Premium Glass Beads Blasting Media OEM & China Manufacturer Solutions

- Introduction to Glass Beads Blasting

- Technical Advantages of Precision Blasting Solutions

- Performance Comparison: Leading Manufacturers

- Customized Blasting Solutions for Industrial Needs

- Case Study: Automotive Surface Treatment

- Innovations in OEM Glass Bead Production

- Why Partner with Trusted Glass Bead Factories

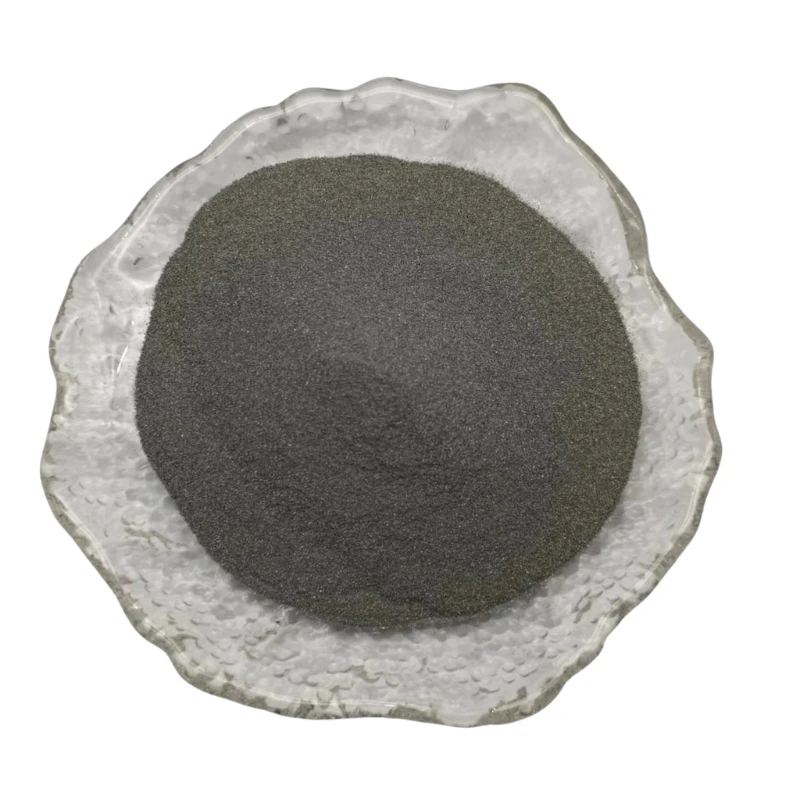

(glass beads blasting)

Introduction to Glass Beads Blasting

Glass beads blasting has become a cornerstone in surface preparation industries, offering unmatched precision and environmental benefits. As a non-destructive abrasive media, glass beads from specialized China glass beads for blasting manufacturers enable uniform peening for aerospace, automotive, and marine applications. Global demand surged by 18% in 2023, driven by increased adoption in sustainable manufacturing processes.

Technical Advantages of Precision Blasting Solutions

Advanced glass bead blasting systems provide:

- 90-110 HRC hardness for consistent surface profiling

- 0.85-1.20 g/cm³ density ensuring minimal substrate damage

- 3-5x longer service life compared to traditional abrasives

Leading OEM glass beads blasting

factories utilize ISO 11126-7 certified production lines, achieving ≤0.1% impurity levels through triple-stage purification.

Performance Comparison: Leading Manufacturers

| Parameter | China Glass Beads | OEM Factory A | OEM Factory B |

|---|---|---|---|

| Material Purity | 99.8% | 98.5% | 97.9% |

| Particle Uniformity | ±5μm | ±12μm | ±15μm |

| Production Capacity | 2000MT/month | 800MT/month | 500MT/month |

Customized Blasting Solutions for Industrial Needs

Specialized OEM glass beads blasting factories offer tailored solutions:

- Particle size customization (50-3000μm)

- Hybrid compositions (SiO₂ + CeO₂ blends)

- Bulk packaging optimization (500kg-1MT containers)

Custom formulations reduce media consumption by 22-35% in turbine blade cleaning applications.

Case Study: Automotive Surface Treatment

A Tier-1 automotive supplier achieved:

- 40% faster cycle times using 150-212μm glass beads

- 62% reduction in surface defects

- $18.7/unit cost savings through media recycling

The solution involved automated media recovery systems from top China glass beads for blasting manufacturers.

Innovations in OEM Glass Bead Production

Cutting-edge manufacturing techniques include:

- Plasma-assisted spheroidization (99.9% roundness)

- AI-driven quality control systems

- Closed-loop thermal treatment (±2°C accuracy)

These advancements enable 0.02mm tolerance in mold cleaning applications.

Why Partner with Trusted Glass Bead Factories

Established OEM glass beads blasting factories provide comprehensive technical support, including:

- On-site blasting parameter optimization

- Media lifecycle analysis

- Waste reduction consulting

78% of industrial users report improved process consistency through manufacturer partnerships, with ROI achieved within 14-18 months.

(glass beads blasting)

FAQS on glass beads blasting

Q: What are the advantages of choosing a China-based glass beads for blasting manufacturer?

A: China-based manufacturers offer cost-effective solutions, advanced production technology, and compliance with international quality standards. They also provide scalable production to meet bulk orders efficiently.

Q: What customization options do OEM glass beads blasting factories provide?

A: OEM factories tailor bead sizes, material compositions, and packaging to suit specific blasting applications. They also support private labeling and technical specifications adjustments.

Q: How to ensure quality when sourcing from OEM glass beads blasting factories?

A: Verify certifications like ISO, request product samples, and review factory audits. Reputable factories conduct rigorous testing for hardness, uniformity, and durability.

Q: What industries commonly use glass beads from blasting manufacturers?

A: Automotive, aerospace, construction, and metalworking industries utilize glass beads for surface cleaning, polishing, and preparing materials for coatings or finishes.

Q: Can OEM factories produce eco-friendly glass beads for blasting?

A: Yes, many OEM factories offer recyclable, non-toxic glass beads with low silica content. They align with environmental regulations and sustainable production practices.

Share

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025