china fly ash and cement

The Role of Fly Ash in the Cement Industry in China

Fly ash, a byproduct of coal combustion in power plants, has garnered significant attention in the construction and cement industries in China. With the rapid industrialization and urbanization that the country has experienced over recent decades, the demand for cement has surged. Concurrently, environmental concerns related to waste disposal from coal-burning power plants have stimulated interest in the beneficial reuse of fly ash. This article explores the role of fly ash in the cement industry, its benefits, and future prospects, particularly in the context of China.

The Significance of Fly Ash

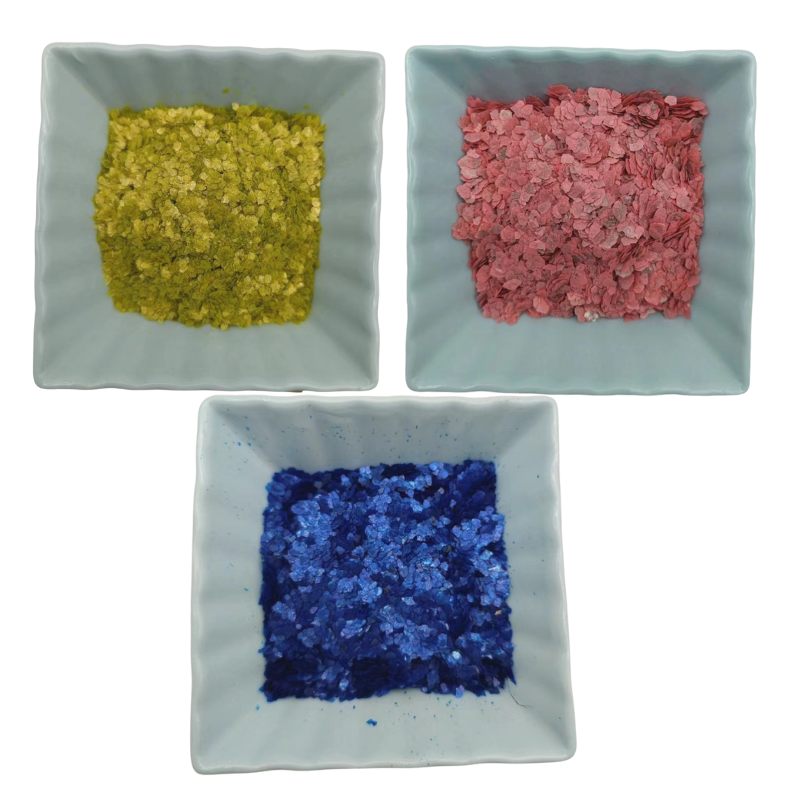

Fly ash is primarily composed of silica, alumina, and iron, making it a perfect candidate for use in cement production. In China, fly ash is increasingly recognized not merely as waste but as a valuable resource. According to the China Building Materials Federation, nearly 20% of the cement produced in China in recent years has included fly ash as a supplementary cementitious material (SCM). This incorporation helps improve the properties of concrete, enhancing its workability, durability, and resistance to chemical attack.

Environmental Benefits

The utilization of fly ash in cement production presents substantial environmental benefits. First, it reduces the amount of waste sent to landfills, thereby mitigating land use and environmental degradation associated with waste disposal. In China, where coal is a major energy source, power plants produce vast quantities of fly ash. By reusing this byproduct, the cement industry plays a crucial role in supporting the circular economy, aligning with national goals for sustainable development.

Additionally, using fly ash can lead to lower greenhouse gas emissions associated with cement production. Cement manufacturing is one of the largest sources of carbon dioxide emissions globally, primarily due to the calcination of limestone and fuel consumption. Replacing a portion of Portland cement with fly ash can reduce the carbon footprint of concrete products, making construction more sustainable.

Performance Advantages

china fly ash and cement

When fly ash is incorporated into cement, it contributes to improved physical properties of concrete. High-quality fly ash enhances the strength and overall quality of concrete, especially in long-term performance. The pozzolanic reactions between the silica in fly ash and calcium hydroxide during hydration result in lower permeability and increased resistance to chloride and sulfate attacks, which are critical for infrastructure longevity.

Moreover, the improved workability offered by fly ash can lead to reduced water content in concrete mixes, which ultimately enhances strength and durability. This is especially important in a country like China, which is continuously expanding its infrastructure to meet the demands of urbanization.

Challenges and Future Prospects

Despite the benefits of using fly ash in cement, challenges persist. The quality of fly ash can vary significantly based on the source and combustion conditions. Ensuring consistent quality standards is essential for its effective integration into cement production. Additionally, with the growing energy transition towards renewable sources, the availability of fly ash may decline, posing questions about future supply.

To address these challenges, researchers and industry practitioners in China are focusing on developing advanced processing techniques to enhance fly ash quality and ensure its suitability for various applications. Furthermore, policies promoting sustainable construction methods and recycling practices could provide much-needed support for expanding fly ash utilization.

Conclusion

In conclusion, fly ash represents a valuable resource for the cement industry in China, providing numerous environmental and performance advantages. As the country continues to grapple with the dual challenges of rapid urbanization and environmental sustainability, integrating fly ash into cement production stands out as a practical solution. By promoting the recycling of fly ash, China can not only reduce waste and emissions but also enhance the quality and durability of its concrete structures, paving the way for a more sustainable future.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025