talc use

The Role and Impact of Talc Use in Various Industries

Talc, a naturally occurring mineral composed of magnesium, silicon, and oxygen, has been utilized for centuries in various industries due to its unique properties. With its softness and effectiveness as a lubricant, talc finds applications in everything from cosmetics to pharmaceuticals, ceramics, and even food processing. However, its use has come under scrutiny in recent years, primarily due to health concerns associated with talc containing asbestos—a known carcinogen. This article explores the significant uses of talc, its benefits, risks, and the evolving regulatory landscape surrounding its usage.

In the cosmetics industry, talc is commonly used as an ingredient in products such as baby powder, face powders, and blushes. Its ability to absorb moisture, reduce friction, and provide a smooth texture makes it a popular choice among manufacturers. Talc also helps in improving product spreadability and dispersibility. Despite these benefits, concerns have arisen about the potential for talc to be contaminated with asbestos during mining. This has led to significant media coverage and consumer awareness, prompting many companies to reformulate their products and prioritize safety.

The pharmaceutical industry also utilizes talc in various applications, primarily as an excipient in tablet formulations. Talc aids in the manufacturing process by improving the flow properties of powders and preventing clumping. Furthermore, its inert nature makes it a suitable agent for use in pharmaceutical products. However, as with cosmetics, the purity of talc is paramount. Pharmaceutical companies have increasingly focused on sourcing talc from suppliers who can guarantee asbestos-free products.

talc use

In the realm of manufacturing, talc is frequently employed in the production of plastics, rubber, and ceramics. Its properties enhance the strength, durability, and heat resistance of these materials. For example, in the automotive industry, talc-filled polypropylene is used to produce lighter parts, contributing to fuel efficiency. In ceramics, talc is vital for improving the plasticity and workability of clays. Nevertheless, manufacturers are urged to evaluate the source of talc used in their products to mitigate any health risks.

The food industry also benefits from talc, where it serves as an anti-caking agent and processing aid. Talc is safe for consumption in regulated amounts and is used in powdered food products, ensuring they remain free-flowing and retain their quality. However, public perception of talc has shifted, leading some companies to seek alternatives that do not carry the same level of scrutiny.

Regulatory bodies worldwide have responded to health concerns related to talc use, prompting stricter guidelines and testing protocols. The United States Food and Drug Administration (FDA) and other international organizations monitor talc products to ensure they are free from harmful contaminants. Companies are increasingly encouraged to provide transparency regarding their sourcing and testing processes, demonstrating their commitment to consumer safety.

In conclusion, while talc remains a versatile and valuable mineral across various industries, the associated health risks have prompted a reevaluation of its application. With heightened awareness and regulatory oversight, the industry is witnessing a shift towards safer alternatives and stricter quality control measures. As consumers grow more discerning about ingredient safety, manufacturers must adapt their practices and innovate solutions that maintain quality while prioritizing health. The future of talc use hinges upon balancing its beneficial properties with the imperative for safety in an increasingly health-conscious market.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

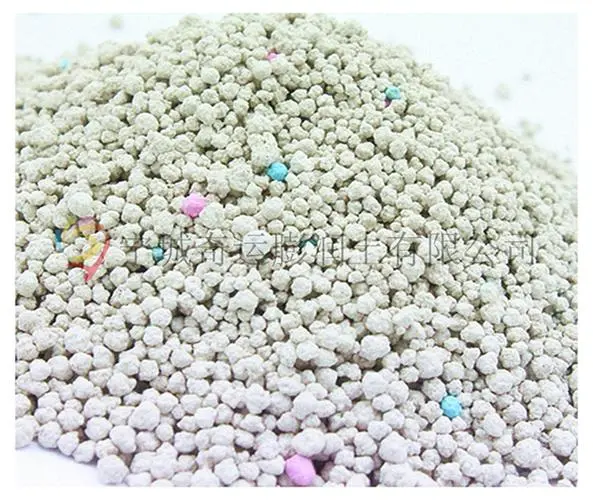

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025