Manufacturers of Custom Silicone Powder with 325 Mesh Size for Various Applications

Custom Silicon Powder 325 Mesh Size Manufacturers A Comprehensive Overview

In the realm of advanced materials, silicon powder plays a pivotal role in various industries, from electronics to pharmaceuticals. One specific grade that has gained significant attention is the 325 mesh size silicon powder, known for its fine particle size and versatile applications. This article delves into the characteristics, manufacturing processes, and the importance of sourcing from custom silicon powder manufacturers.

Understanding Silicon Powder and Its Applications

Silicon powder is derived from silicon, a fundamental element with properties that make it indispensable in many applications. The term 325 mesh refers to the size of the particles, with a mesh number indicating the number of openings per inch in a screen used to separate particles. A 325 mesh means that the powder's particle size is fine, typically around 44 microns or smaller. Due to its small particle size, 325 mesh silicon powder exhibits unique properties such as enhanced reactivity, increased surface area, and improved dissolution rates, making it suitable for various applications.

Some common uses include

- Electronics Silicon powder is crucial in the production of semiconductors and photovoltaic cells. Its fine form supports better conductivity and efficiency in these devices. - Additives In the manufacturing of paints, coatings, and plastics, silicon powder acts as a filler or additive, improving mechanical properties and providing better texture. - Pharmaceuticals The powder serves as an excipient in drug formulations, allowing for better bioavailability and stability of active ingredients. - Cosmetics Silicon powder contributes to skin conditioning and oil absorption in various cosmetic products.

The Importance of Customization

The need for customized silicon powder arises from the diverse requirements across different industries. Manufacturers often require specific grades tailored to their unique applications, necessitating collaboration with custom silicon powder manufacturers who understand these specifications.

custom silicon powder 325 mesh size manufacturers

1. Quality Control Established manufacturers maintain stringent quality control measures to ensure that the silicon powder meets the desired particle size, purity, and consistency. This is crucial for applications where even minor variations can impact performance and safety.

2. Tailored Applications Custom manufacturers can adjust the properties of the silicon powder, such as its surface area, morphology, and reactivity, allowing businesses to procure materials that best suit their production processes.

3. Cost-Effectiveness By sourcing from specialized manufacturers, companies can optimize their supply chain, reducing waste and costs associated with unsuitable materials.

Manufacturing Processes

The process of manufacturing 325 mesh silicon powder involves several steps, each contributing to the final product's quality

- Raw Material Selection High-purity silicon is sourced, usually derived from silica sand. The choice of raw materials is crucial for the overall purity of the final product. - Crushing and Milling The raw silicon undergoes crushing and milling processes to achieve the desired particle size. Equipment like ball mills or jet mills are commonly used for this purpose. - Sieving After milling, the product is sieved to separate particles that do not meet the 325 mesh specification. This ensures that the final powder is uniformly sized and appropriate for its intended applications. - Packaging The final step involves packaging the silicon powder in airtight containers to preserve its quality during storage and transportation.

Conclusion

In conclusion, the demand for high-quality custom silicon powder, particularly in the 325 mesh size, reflects the evolving needs of modern industries. Collaborating with specialized manufacturers can provide companies with the tailored materials required to excel in their respective fields. As technological advancements continue to shape how industries operate, the importance of sourcing customized silicon powder will likely increase, underscoring the role of innovation in material science. As businesses seek to maintain a competitive edge, understanding and investing in quality silicon powder will remain a critical component of their success.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

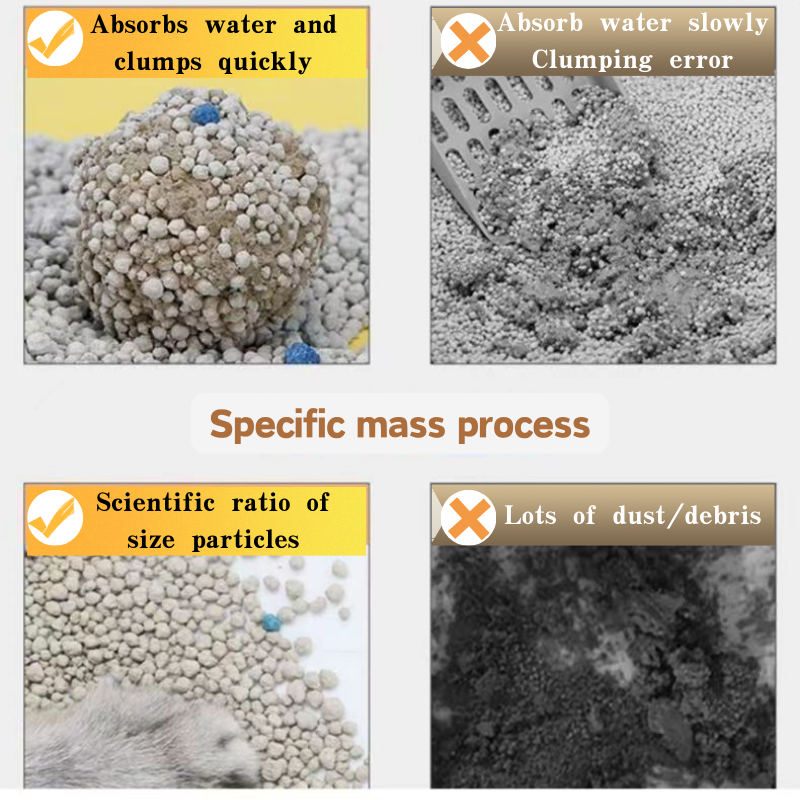

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025