glass pebbles factory

The Allure of Glass Pebbles An Inside Look at a Glass Pebbles Factory

In the quaint corners of artisan towns and bustling marketplaces, glass pebbles have become a popular decorative item, adored for their vibrant colors and smooth texture. Behind their mesmerizing appeal lies an intricate process carried out in glass pebbles factories, where creativity and craftsmanship unite to create these exquisite pieces.

The Process of Creation

The journey of a glass pebble begins with raw materials, predominantly silica sand, soda ash, and limestone. The combination of these materials is heated in a furnace to temperatures exceeding 1,400 degrees Celsius until they melt into a molten glass. This molten glass is then carefully poured into molds or shaped into pebbles by skilled artisans.

One of the most fascinating aspects of glass pebble manufacturing is the incorporation of color. Factories often use metal oxides and other coloring agents to create a wide palette of hues, from the rich blues reminiscent of ocean waves to vibrant reds echoing the warmth of sunsets. The color is painstakingly mixed in during the melting stage, ensuring that every pebble possesses a unique charm. After pouring, the glass cools and solidifies into its pebble form.

After the Molten Stage

Once the pebbles are formed, they are subjected to a rigorous polishing process. This stage is crucial, as it transforms the rough glass pieces into smooth, lustrous stones that are visually appealing and safe for handling. Workers use both manual and mechanical polishing techniques, employing tools that carefully grind down any imperfections while enhancing the pebble's natural luminosity.

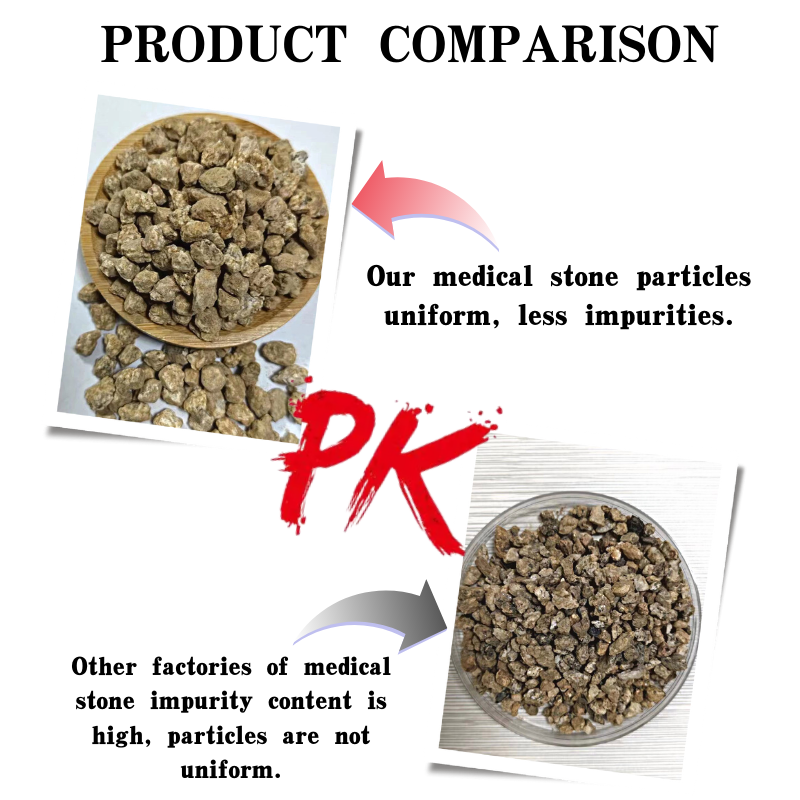

Quality control is essential in this phase. Each pebble is inspected for flaws any that fail to meet the factory's high standards are discarded. The factory prides itself on its commitment to delivering only the finest products, understanding that customers expect quality and aesthetic beauty.

glass pebbles factory

Sustainability Practices

In recent years, awareness regarding environmental impact has surged, prompting many glass pebbles factories to adopt sustainable practices. This includes sourcing recycled glass, which not only reduces waste but also lessens the energy required for production. By reusing glass products, factories can create new pebbles while minimizing their carbon footprint.

Furthermore, many factories now utilize eco-friendly packaging materials and energy-efficient machinery. These measures ensure that the joy of owning beautifully crafted glass pebbles does not come at the expense of the planet.

Uses Beyond Decoration

Glass pebbles have a versatile appeal, serving various purposes beyond decoration. They are often used in landscaping, as fillers for vases, and even in aquariums where they provide an eye-catching substrate. Their practicality, combined with aesthetic qualities, means that they can enhance both indoor and outdoor settings.

Craft enthusiasts also make use of glass pebbles in DIY projects. From garden paths to artwork, their applications are limited only by creativity. This adaptability has contributed to the growing popularity of glass pebbles across multiple markets, making them a sought-after commodity.

Conclusion

The journey of glass pebbles from raw materials to finished products is a testament to the blend of artistry and industry. The dedication of the workers, the sustainable practices of the factories, and the endless possibilities for their use make glass pebbles a remarkable product, cherished by people around the globe. Whether as decorative elements in a home or as part of a grander design scheme, glass pebbles continue to charm and inspire, sparkling brightly in the hearts and homes of their admirers.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025