white glass beads factory

The Art and Science of White Glass Beads Manufacturing

In the world of artistry and decoration, white glass beads have carved a niche for themselves as both aesthetic and functional materials. Their elegance and versatility make them a favorite among artisans and designers alike. Behind the enchanting beauty of these glass beads lies a sophisticated manufacturing process that combines traditional craftsmanship with modern technology.

The Sourcing of Raw Materials

The journey of creating white glass beads begins with the careful selection of raw materials. High-quality silica sand is the primary ingredient, along with various metal oxides that serve as colorants. For white glass beads, the focus is on purity and clarity, ensuring that the final product radiates an appealing shine. The quality of materials influences not just the appearance, but also the durability and overall performance of the beads.

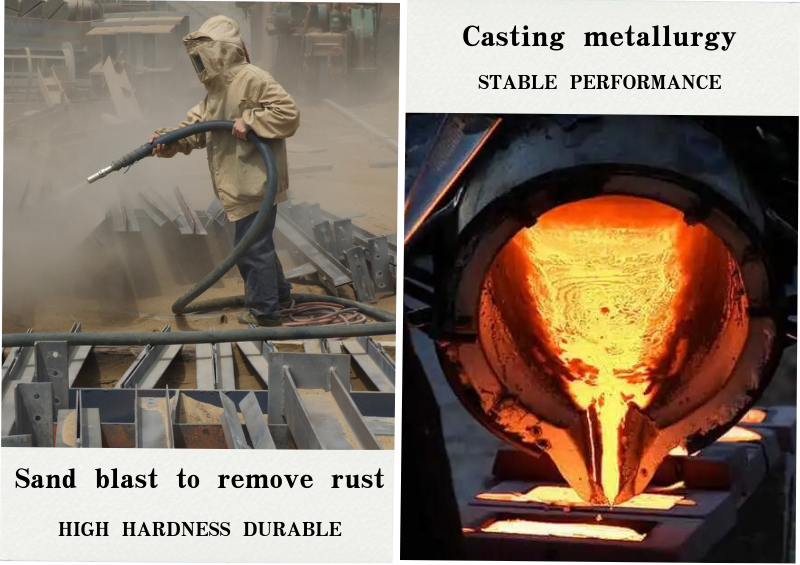

The Melting Process

Once the raw materials are sourced, they undergo a precise melting process. The mixture is heated in large furnaces at temperatures exceeding 1400 degrees Celsius. This intense heat transforms the raw materials into molten glass, a thick, viscous liquid that can be shaped and formed. The consistency of the melt is crucial; it should neither be too thick nor too runny to ensure the beads maintain their shape during cooling.

Forming the Beads

After achieving the desired melt consistency, the next step involves forming the beads. Various techniques can be employed for this purpose, including hand-rolling, mold pressing, or machine extrusion. Each method has its unique characteristics. Hand-rolling allows for creative expression, producing one-of-a-kind beads, whereas machine methods can yield uniform, mass-produced beads that cater to larger demands.

white glass beads factory

Once shaped, the beads need to be cooled gradually in a controlled environment. This annealing process helps to relieve any internal stress within the glass, ensuring that the beads do not crack or shatter easily. The cooling process can take several hours, during which the beads solidify into their final form.

Finishing Touches

The manufacturing of white glass beads does not end with cooling. The finishing touches are crucial in enhancing their beauty. Beads are often polished to achieve a smooth surface and a glossy finish. Additional treatments can include the application of coatings to enhance their shine or to create unique effects such as iridescence.

Quality Control

Quality control plays an essential role in the production of white glass beads. Skilled technicians inspect each batch for uniformity in size, shape, and color. They also conduct tests for durability to ensure the beads can withstand the rigors of crafting and daily use. Products that do not meet the stringent quality standards are discarded, ensuring only the finest beads reach customers.

Conclusion

The production of white glass beads is a precise blend of art and science, transforming raw materials into beautiful, functional items. Whether used in jewelry making, home décor, or various crafts, these beads represent a sophisticated manufacturing process rooted in tradition yet enhanced by modern technology. As we continue to innovate in crafting techniques and materials, the allure of white glass beads will undoubtedly continue to shine bright in the creative world.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025