type f fly ash factory

Exploring the Types and Benefits of Fly Ash from Factories

Fly ash, a byproduct of coal combustion in power plants, has gained significant attention in recent years for its versatility and eco-friendly characteristics. As industries focus on sustainability and resource optimization, the production and utilization of fly ash have become increasingly relevant. This article examines the various types of fly ash produced by factories, their properties, and their applications in construction and other fields.

What is Fly Ash?

Fly ash is a fine powder composed of silica, alumina, and iron. It is produced when coal is burned to generate electricity. The combustion process results in the formation of fine particles that are carried off by flue gases and captured by electrostatic precipitators or bag filters. Once collected, fly ash can be processed and utilized in various applications, primarily in the construction industry.

Classification of Fly Ash

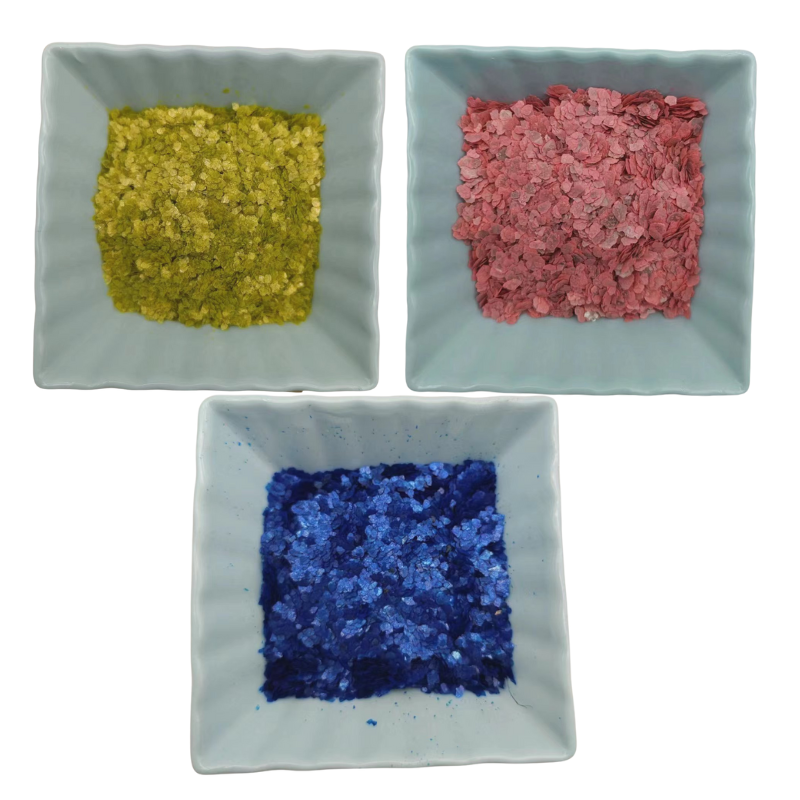

Fly ash is typically classified into two main types based on its composition and physical properties Class F fly ash and Class C fly ash.

1. Class F Fly Ash Class F fly ash is produced from the combustion of anthracite or bituminous coal. It typically contains more than 70% silica and alumina, which makes it highly pozzolanic. Pozzolans are materials that react chemically with lime in the presence of moisture to form compounds possessing cementitious properties. Class F fly ash is often used in producing concrete, providing improved strength and durability. It is particularly beneficial in structures exposed to harsh environmental conditions, making it ideal for infrastructure projects.

2. Class C Fly Ash Class C fly ash is derived from the combustion of lignite or sub-bituminous coal, containing a higher concentration of calcium, generally around 20-30%. Due to its higher calcium content, Class C fly ash boasts self-cementing properties, allowing it to be used as a partial replacement for Portland cement in concrete mixes. This type of fly ash is advantageous in applications requiring rapid strength gain, making it popular in pre-cast concrete products and rapid construction projects.

Benefits of Using Fly Ash

The utilization of fly ash offers numerous benefits, both environmentally and economically

type f fly ash factory

1. Sustainability By repurposing fly ash, industries can reduce waste sent to landfills. This contributes to a more sustainable approach to construction, effectively minimizing the carbon footprint associated with traditional cement production.

2. Enhanced Concrete Properties Incorporating fly ash into concrete improves its workability, durability, and resistance to sulfate attacks and alkali-silica reactions. These enhanced properties extend the lifespan of concrete structures, reducing maintenance costs over time.

3. Cost-Effectiveness Fly ash can serve as a cheaper alternative to traditional cement. Utilizing it in concrete mixes can lead to savings in raw material costs, while also reducing the energy required for cement production.

4. Energy Efficiency The production of cement is energy-intensive. By substituting cement with fly ash, industries can lower energy consumption, leading to a smaller overall environmental impact.

Applications in Construction

Beyond its role in concrete production, fly ash is utilized in several construction applications, including

- Soil Stabilization Fly ash can be used to improve the strength and stability of weak soils, making it an essential material for road construction and other civil engineering projects. - Lightweight Fill Materials Due to its low density, fly ash is often employed as a lightweight fill material in embankments and backfills.

- Bricks and Blocks Fly ash is used as a key ingredient in the manufacture of fly ash bricks and blocks, which are known for their strength and thermal insulation properties.

Conclusion

Fly ash production and utilization present a unique opportunity for industries to enhance sustainability while benefiting economically. The classification into Class F and Class C fly ash indicates their varied applications in construction, while their inherent properties contribute to the durability and longevity of structures. As we move towards a more sustainable future, the use of fly ash is poised to play a crucial role in the construction and building materials sectors. By embracing this byproduct, industries not only support environmental conservation but also promote innovative practices that will shape the future of construction.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025