titanium dioxide for pai. factories

The Role of Titanium Dioxide in PAI Factories An In-Depth Look

Introduction

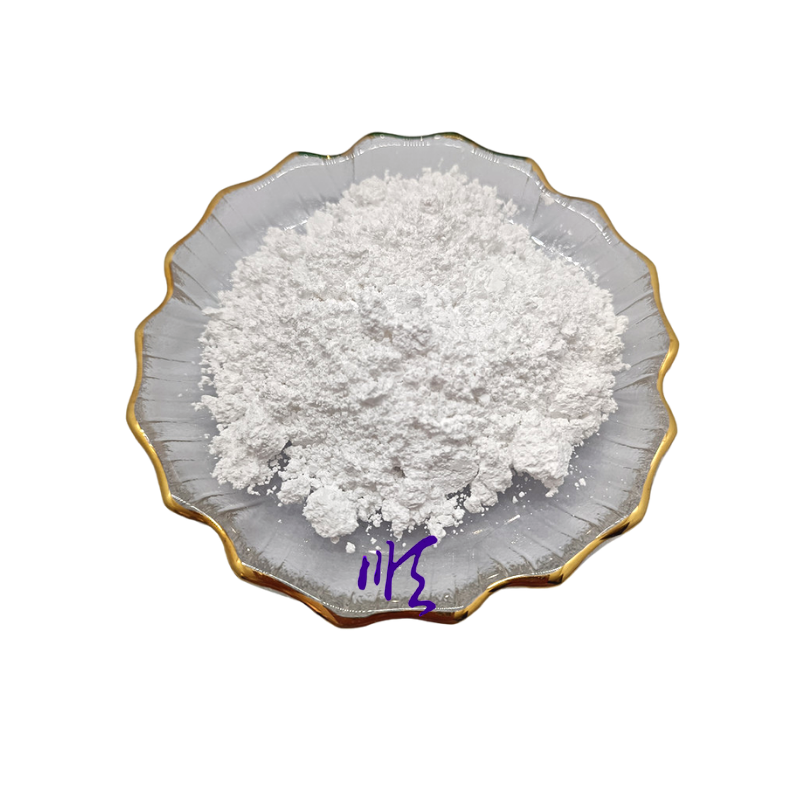

Titanium dioxide (TiO2) is an essential compound widely used in various industries, primarily known for its exceptional brightness and opacity. Recently, its application in the production of polyamide-imide (PAI) has garnered attention, particularly in factory settings. This article delves into the significance of titanium dioxide in PAI factories, exploring its benefits, applications, and potential challenges.

Understanding Titanium Dioxide

Titanium dioxide is a white pigment with a high refractive index, making it an excellent choice for providing brightness and hiding power in various formulations. In the context of PAI, TiO2 plays a crucial role as a filler, enhancing both the performance and aesthetic qualities of the final product. PAI is a high-performance polymer characterized by excellent thermal stability, mechanical strength, and chemical resistance, making it ideal for demanding applications in the aerospace, automotive, and electrical industries.

Benefits of Titanium Dioxide in PAI Production

1. Enhanced Mechanical Properties The inclusion of titanium dioxide as a filler in PAI contributes to improved mechanical strength. This enhancement is crucial in applications that involve high stress and extreme conditions, where the durability of materials is paramount.

2. Thermal Stability Titanium dioxide can help maintain the thermal stability of PAI, ensuring that the polymer retains its properties even at elevated temperatures. This characteristic is particularly important in sectors such as aerospace, where materials are subjected to significant thermal fluctuations.

3. UV Protection PAI products often face exposure to ultraviolet (UV) light, which can degrade materials over time. Titanium dioxide serves as a UV absorber, increasing the longevity and reliability of PAI components by minimizing light-induced wear.

4. Aesthetic Qualities The white pigment provided by titanium dioxide enhances the aesthetic appeal of PAI products. Its ability to provide excellent opacity and brightness is advantageous in applications where appearance is crucial, such as in consumer electronics and automotive coatings.

titanium dioxide for pai. factories

Applications of Titanium Dioxide in PAI Factories

In PAI factories, titanium dioxide is utilized in several ways

1. Film and Coatings TiO2 is commonly used in the formulation of films and coatings, which are integral to protecting surfaces in various industries. Its inclusion enhances the durability and lifespan of coatings applied to metals, electronics, and other materials.

2. Composite Materials The addition of titanium dioxide can enhance the performance of composite materials, leading to products that are lightweight yet strong. This property is vital in sectors like aerospace, where reducing weight while maintaining strength is essential.

3. Electrical Insulation PAI’s excellent electrical insulating properties make it suitable for applications in electrical components. Titanium dioxide contributes to this by providing additional resistance to electrical discharge, thereby improving safety and performance.

Challenges and Considerations

While the benefits of titanium dioxide in PAI factories are significant, some challenges must be addressed. Firstly, the sourcing and processing of titanium dioxide can have environmental impacts, including mining activities that may disrupt ecosystems. Factories must adopt sustainable practices to mitigate these effects.

Secondly, the handling of titanium dioxide requires careful safety measures. Inhalation of fine TiO2 particles can pose health risks, necessitating proper ventilation and protective equipment in manufacturing environments. Ensuring worker safety while maintaining productivity is a critical balance that factories must achieve.

Conclusion

Titanium dioxide's role in PAI factories is indispensable, offering numerous benefits ranging from enhanced mechanical properties to improved thermal stability. As industries continue to evolve and demand higher performance materials, the integration of TiO2 in PAI manufacturing will likely increase. However, addressing the associated challenges responsibly will be crucial for achieving sustainable production practices. As we move forward, the innovation and application of titanium dioxide in PAI will play a vital role in shaping the future of high-performance materials.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025