Talc Powder Production Companies and Their Manufacturing Facilities Globally

The Role of Talc Powder Manufacturers in Various Industries

Talc powder, a versatile mineral known for its softness and chemical inertness, is widely used across numerous industries, including cosmetics, pharmaceuticals, food, and plastics. The manufacturing of talc powder is a significant sector, with specialized factories committed to producing high-quality talc products that meet the specific needs of these diverse applications. Understanding the processes involved in the production of talc powder and the roles of manufacturers can provide insight into its importance in modern industry.

The Importance of Talc Powder

Talc powder is composed mainly of magnesium, silicon, and oxygen and is renowned for its lubricating properties. This makes it particularly valuable in industries where friction reduction is crucial. For example, in cosmetics, talc is used in the formulation of face powders, blushes, and other beauty products to enhance smoothness, absorb moisture, and prevent caking. In the pharmaceutical industry, talc serves as a filler and lubricant in tablet formulations, ensuring consistent tablet quality.

Furthermore, talc powder plays a critical role in the food industry, where it acts as an anti-caking agent and is useful in processing various food products. Its non-toxicity allows for safe usage in food applications, making it a preferred choice for many manufacturers.

The Manufacturing Process

The production of talc powder involves several key steps. It starts with the extraction of talc from deposits found in the earth's crust. Talc mining typically occurs in mountainous regions where metamorphic rocks contain high concentrations of talc. After extraction, the raw talc undergoes a series of processes including crushing, grinding, and air classification. These processes ensure that the talc is reduced to the desired particle size and purity level.

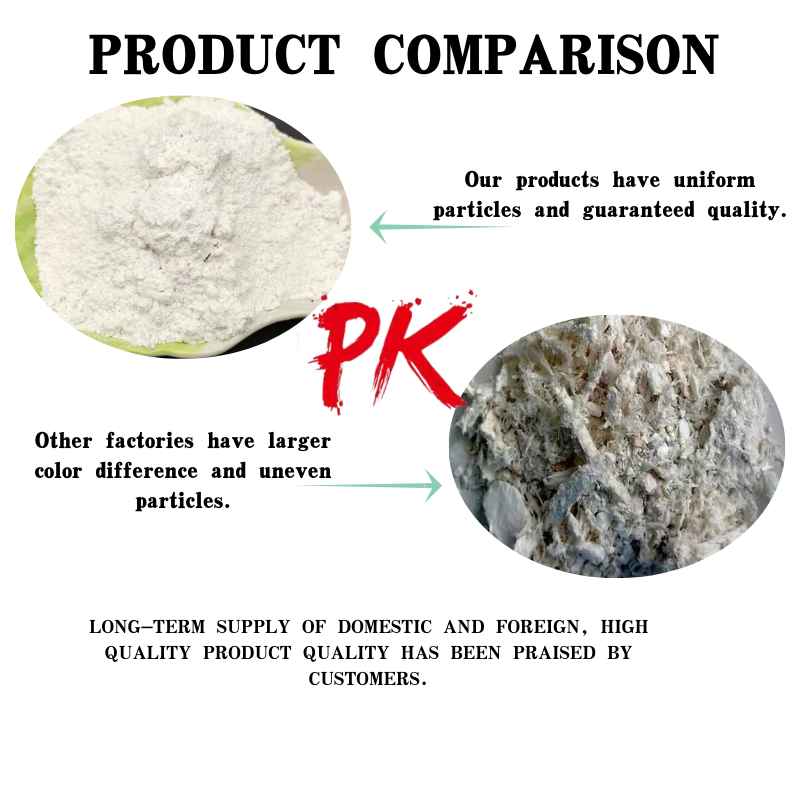

Once the talc powder is processed, manufacturers perform tests to guarantee product quality. This includes analyzing the talc for impurities and assessing its physical properties, such as particle size distribution, brightness, and moisture content. Only after passing these stringent quality controls can talc powder be packaged and sent to various industries.

talc powder manufacturers factories

Challenges Facing Talc Powder Manufacturers

Despite the many uses of talc powder, manufacturers face several challenges. One of the primary issues is the increasing scrutiny regarding the safety of talc, particularly in cosmetic applications. Concerns about potential asbestos contamination and its links to health risks have led to more rigorous testing and regulatory standards. Consequently, talc powder manufacturers must invest in extensive research and development to ensure their products are safe and compliant with industry regulations.

Additionally, fluctuations in market demand can pose challenges. As industries evolve and new materials emerge, talc's position as a preferred ingredient may be threatened. Manufacturers must continuously innovate and adapt their product offerings to stay competitive in the market.

The Future of Talc Powder Manufacturing

Looking ahead, the future of talc powder manufacturing appears promising despite the challenges. With advancements in technology, manufacturers are exploring new applications for talc powder, particularly in the realm of green technology and sustainable materials. The ongoing development of biodegradable plastics could create new avenues for talc usage as a filler and reinforcing agent.

Moreover, the growing trend toward organic and natural products in cosmetics and personal care items may lead to a resurgence in talc's popularity, given its natural origin and inherent properties. Manufacturers who can address safety concerns while emphasizing the benefits of talc may find significant opportunities in this evolving market.

In conclusion, talc powder manufacturers play a vital role in supplying various industries with essential materials. By ensuring high-quality production, navigating regulatory landscapes, and innovating for the future, these manufacturers can continue to meet the demands of their clients. As industries seek sustainable and effective solutions, talc powder's adaptability and unique properties will likely sustain its relevance and importance in the manufacturing landscape for years to come.

Share

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025