silica fume company manufacturer

Understanding the Role of Silica Fume in Construction A Guide to Manufacturers

Silica fume, also known as microsilica, is a byproduct of the silicon and ferrosilicon industry that has gained significant attention over the years for its superior properties. As construction practices evolve, the demand for high-performance materials continues to rise, making silica fume a critical component in modern concrete production. In this article, we will delve into the role of silica fume, its benefits, and what to consider when selecting a silica fume manufacturer.

What is Silica Fume?

Silica fume is an ultra-fine material, typically composed of more than 90% silicon dioxide (SiO2). It consists of spherical particles that are approximately 100 times smaller than average cement particles. This unique size and shape contribute to its pozzolanic properties, allowing it to chemically react with calcium hydroxide in the presence of water to form additional cementitious compounds. As a result, silica fume enhances the overall strength and durability of concrete mixtures.

Benefits of Using Silica Fume

1. Increased Strength Concrete containing silica fume exhibits a dramatic increase in compressive and flexural strength. This strength advantage allows for the construction of lighter and more durable structures, optimizing material usage and reducing construction costs.

2. Improved Durability Silica fume enhances the durability of concrete by reducing permeability and increasing resistance to aggressive chemicals, especially sulfates and chlorides. This characteristic makes it ideal for infrastructure projects, such as bridges and highways, which are exposed to harsh environmental conditions.

3. Reduced Shrinkage The addition of silica fume can significantly reduce the shrinkage of concrete, which minimizes cracking and enhances longevity. This property is particularly beneficial in applications such as industrial floors and precast elements.

4. Sustainability Utilizing silica fume in concrete not only improves its performance but also contributes to sustainability efforts. As a supplementary cementitious material (SCM), it partially replaces Portland cement, thereby reducing the carbon footprint associated with concrete production.

silica fume company manufacturer

Selecting a Silica Fume Manufacturer

When considering the use of silica fume in your construction projects, selecting a reputable manufacturer is crucial. Here are several factors to keep in mind

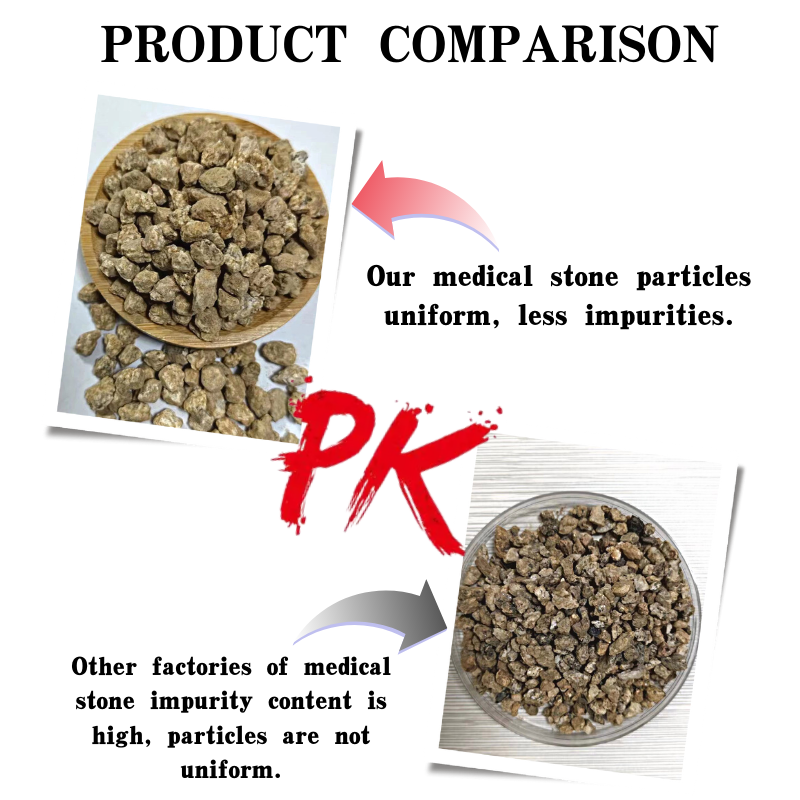

1. Quality Assurance The quality of silica fume can vary significantly between manufacturers. It's essential to ensure that the manufacturer adheres to stringent quality control measures and provides third-party testing results to verify the product's properties.

2. Purity Level The purity of silica fume, generally expressed as a percentage of SiO2 content, is important. A higher purity level often translates to better performance in concrete applications. Opt for manufacturers that can guarantee high purity silica fume.

3. Consistency in Supply Reliability in supply is critical for timely project completion. Choose manufacturers with a strong track record of fulfilling orders and maintaining consistent product availability.

4. Technical Support A quality silica fume manufacturer should offer technical support to help integrate silica fume into concrete mixtures effectively. This may include guidance on mix designs, application techniques, and troubleshooting potential issues.

5. Sustainability Practices Investigate the environmental practices of silica fume manufacturers. Those committed to sustainability will often implement environmentally friendly production processes and effective waste management systems.

Conclusion

As the construction industry continues to seek improved materials that enhance performance and sustainability, silica fume stands out as a valuable solution. Understanding its benefits and choosing the right manufacturer can lead to successful project outcomes. By leveraging the impressive properties of silica fume, builders can construct stronger, more durable, and eco-friendly structures that meet the demands of modern society. If you're considering silica fume for your next project, investing time in research and selecting the right supplier will pay dividends in the long run.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025