Reduced Iron Powder: A Revolutionary Product

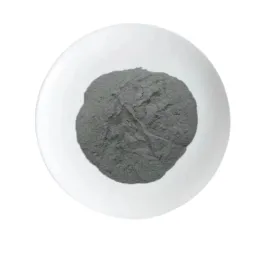

Welcome to our latest company news! Today, we are excited to introduce our newest product, reduced iron powder, also known as sponge iron powder. This innovative material is set to transform various industries with its exceptional properties and wide range of applications. Let's dive into the details of this remarkable product.

High-Quality Reduced Iron Powder for Diverse Applications

Our reduced iron powder is manufactured using state-of-the-art technology, ensuring the highest quality and consistency. This product is widely used in metallurgy, chemical engineering, and powder metallurgy. Its unique sponge-like structure provides excellent reactivity and porosity, making it ideal for direct reduction processes and as a raw material for high-performance alloys. The iron powder is carefully processed to achieve a fine particle size, which enhances its surface area and reactivity, leading to superior performance in various applications.

Advantages of Sponge Iron Powder

The sponge iron powder we offer comes with several advantages. Firstly, its high purity ensures minimal impurities, which is crucial for applications requiring high-quality materials. Secondly, the powder's porous structure allows for efficient gas diffusion, making it perfect for chemical reactions and catalytic processes. Additionally, the iron powder is easy to handle and transport, thanks to its stable physical properties. These features make our sponge iron powder a top choice for industries seeking reliable and efficient materials.

Iron Powder CAS No: Ensuring Safety and Compliance

At our company, safety and compliance are of utmost importance. Our iron powder is registered with a specific CAS number, which is a unique identifier for chemical substances. This ensures that our product meets all regulatory standards and is safe for use in various industrial processes. The CAS number also helps in tracking and managing the material, providing transparency and accountability throughout its lifecycle. By adhering to these standards, we guarantee that our iron powder is of the highest quality and safe for our customers.

Applications of Reduced Iron Powder

The versatility of reduced iron powder makes it suitable for a wide range of applications. In the metallurgical industry, it is used for the production of high-quality steel and alloy powders. In the chemical industry, the iron powder serves as a catalyst for hydrogenation reactions and other chemical processes. Additionally, it is used in the manufacturing of magnetic materials, electronics, and even in the food industry for iron fortification. The fine particle size and high reactivity of our reduced iron powder make it a versatile and valuable material for modern industries.

Reduced Iron Powder FAQs

What is reduced iron powder used for?

Reduced iron powder, also known as sponge iron powder, is used in various industries such as metallurgy, chemical engineering, and powder metallurgy. It is ideal for direct reduction processes, alloy production, and as a catalyst in chemical reactions.

How is reduced iron powder different from regular iron powder?

Reduced iron powder has a unique sponge-like structure, which provides higher reactivity and porosity compared to regular iron powder. This makes it more efficient in applications requiring high reactivity and gas diffusion.

What is the CAS number of iron powder?

The CAS number of iron powder is a unique identifier that ensures the material meets regulatory standards. Our iron powder is registered with a specific CAS number to guarantee safety and compliance.

Is reduced iron powder safe to handle?

Yes, reduced iron powder is safe to handle when proper safety measures are followed. It is important to store and transport the powder in a dry and well-ventilated area to prevent any potential hazards.

What industries benefit the most from reduced iron powder?

Industries such as metallurgy, chemical engineering, powder metallurgy, electronics, and even the food industry benefit significantly from reduced iron powder. Its high reactivity and versatility make it a valuable material for various applications.

Thank you for reading our latest company news! We hope this article has provided you with valuable insights into the features and advantages of our reduced iron powder. For more information or to place an order, please visit our website or contact our sales team. We look forward to serving you!

Share

-

White Silica Fume for Advanced ApplicationsNewsAug.07,2025

-

Shell Soil and Shell Sand: Nature's GiftNewsAug.07,2025

-

Reduced Iron Powder: A Revolutionary ProductNewsAug.07,2025

-

Iron Powder: A Versatile MaterialNewsAug.07,2025

-

Discover the Magic of Tourmaline BallsNewsAug.07,2025

-

Discover the Beauty of Glass MarblesNewsAug.07,2025