pure zeolite manufacturers

The Rise of Pure Zeolite Manufacturers An In-Depth Analysis

In recent years, the demand for zeolite minerals has surged due to their diverse applications across various industries. Pure zeolite manufacturers are at the forefront of this trend, supplying high-quality zeolites that serve in agriculture, environmental remediation, and industrial processes. This article explores the significance of pure zeolite manufacturers, their production processes, the benefits of using zeolites, and the future of this burgeoning industry.

Understanding Zeolites

Zeolites are naturally occurring or synthetic aluminosilicate minerals characterized by their unique crystalline structure and porous nature. They are renowned for their ion-exchange, adsorption, and catalytic properties, making them invaluable in multiple sectors. Natural zeolites like clinoptilolite and mordenite are commonly found deposits, while synthetic zeolites, such as Zeolite A and Zeolite Y, are engineered for specific applications.

The Role of Pure Zeolite Manufacturers

The role of pure zeolite manufacturers is pivotal in maintaining product quality and meeting the growing market needs. These manufacturers focus on extracting zeolite minerals from natural deposits or synthetically producing them while ensuring high purity levels. This purity is essential for various applications, as impurities can significantly alter the material's performance and effectiveness.

Leading manufacturers invest in advanced extraction and processing techniques to produce zeolites that meet stringent quality standards. They utilize state-of-the-art technology, including automated systems and precision machinery, to enhance efficiency and minimize contamination. Moreover, rigorous quality control measures are implemented throughout the production process, ensuring that the final product aligns with industry specifications.

Applications of Pure Zeolites

Pure zeolites are widely used across different industries due to their versatile properties. In agriculture, zeolites act as natural soil amendments, improving soil health and fertility. Their ability to retain water and nutrients benefits crop yields, making them popular among farmers seeking sustainable agriculture solutions.

pure zeolite manufacturers

In environmental applications, zeolites are employed in water purification processes. Their ion-exchange capabilities enable the removal of harmful pollutants, heavy metals, and ammonia from wastewater. This makes them an essential component in the treatment of contaminated water bodies, contributing to environmental conservation efforts.

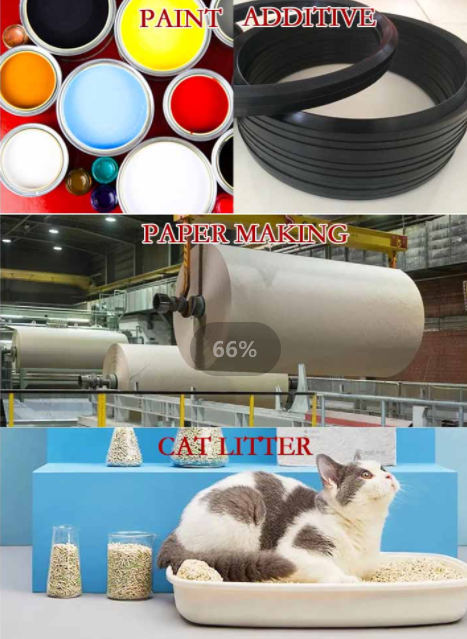

Additionally, the industrial sector utilizes zeolites as catalysts in various chemical reactions, enhancing reaction rates and selectivity. They also find applications in the manufacturing of detergents and as additives in the production of plastics.

Benefits of Using Pure Zeolites

The use of pure zeolites presents several significant benefits. First and foremost, their natural origin and non-toxic nature make them an environmentally friendly choice for numerous applications. This aspect is particularly appealing in a market that is increasingly leaning towards sustainable and eco-friendly solutions.

Furthermore, pure zeolites offer excellent performance characteristics. Their high surface area and porosity enhance their adsorption and ion-exchange capabilities, resulting in more efficient processes in both agricultural and industrial settings. The ability to tailor zeolite properties through synthetic methods allows manufacturers to produce specialized variants that cater to specific client needs.

The Future of Pure Zeolite Manufacturing

As industries continue to evolve, the future of pure zeolite manufacturers looks promising. The increasing awareness of environmental issues and the need for sustainable practices will drive demand for zeolite applications. Innovations in synthetic zeolite production will further expand their usability, creating new market opportunities.

Moreover, with ongoing research into the unique properties of zeolites, manufacturers are likely to discover new applications that can benefit from these minerals. Collaboration between academic institutions and zeolite manufacturers may pave the way for breakthroughs that enhance performance and efficiency.

In conclusion, pure zeolite manufacturers are playing a crucial role in meeting the rising demand for this versatile mineral. Their commitment to producing high-quality zeolites ensures that industries can harness the full potential of these materials. As the market for zeolites continues to grow, manufacturers who prioritize quality, innovation, and sustainability will undoubtedly lead the industry into a promising future. The increasing integration of zeolites in environmentally conscious practices further reflects the valuable contribution they offer to societal growth and ecological preservation.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025