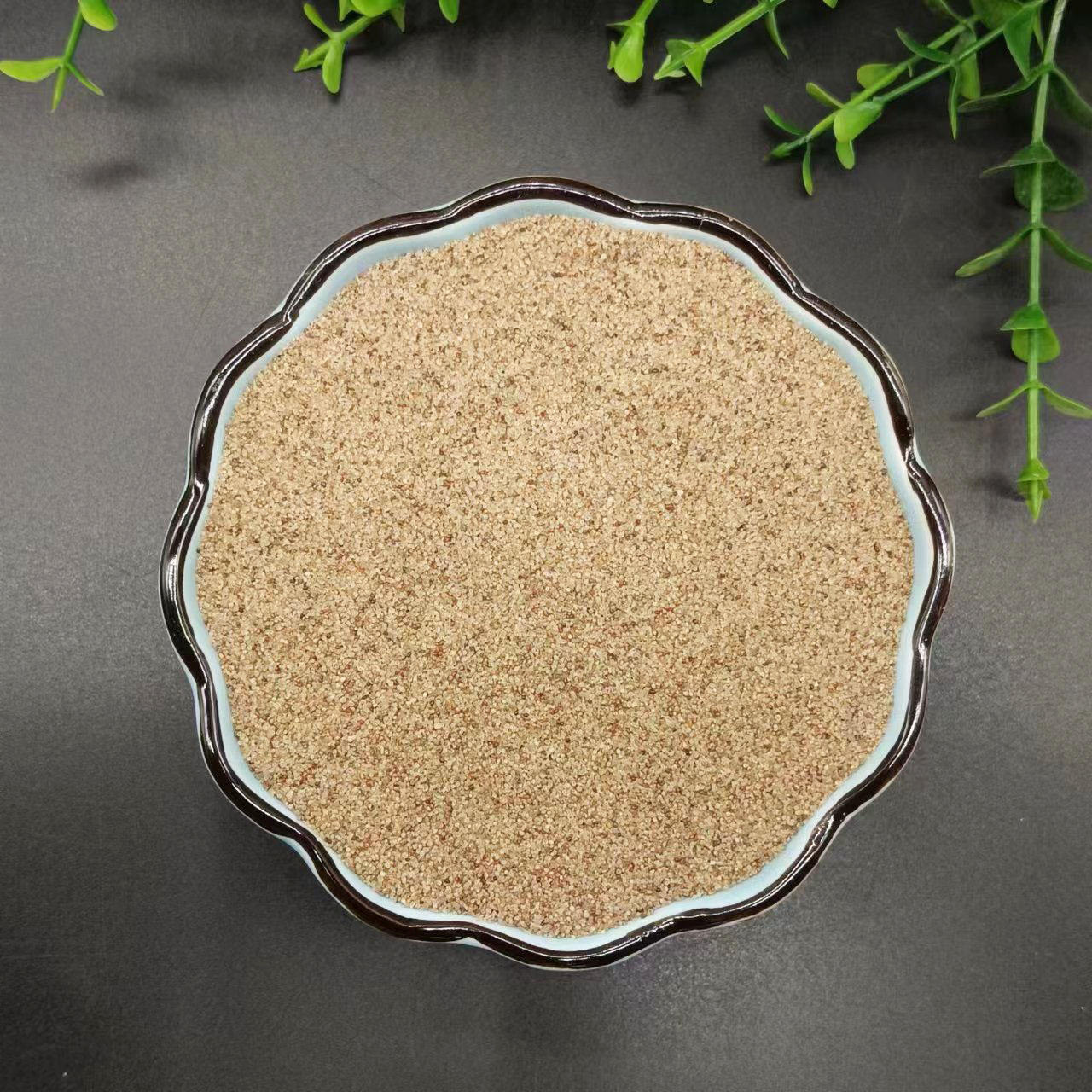

pure iron powder

The Versatility and Applications of Pure Iron Powder

Iron is one of the most abundant elements on Earth, and its versatile properties have made it an essential component in various industries. Among the various forms of iron, pure iron powder stands out due to its unique characteristics and diverse applications. In this article, we will explore what pure iron powder is, its production methods, and its importance in modern technology and industry.

What is Pure Iron Powder?

Pure iron powder is finely divided iron that contains a high percentage of iron, typically over 99.5%. Its fine particles provide an incredibly high surface area, which enhances reactivity and makes it suitable for numerous applications. Unlike conventional steel, which contains various alloying elements, pure iron is known for its excellent magnetic and ductile properties. This makes it an ideal material in sectors that require magnetic characteristics and precise control of physical properties.

Production Methods

The production of pure iron powder involves several methods, each designed to achieve high purity and specific particle size distribution. The most common techniques include

1. Reduction of Iron Oxides This method involves the reduction of iron ore or other iron-containing materials in a controlled environment using agents such as hydrogen or carbon monoxide. The process results in iron powder with a low level of contaminating elements.

2. Electrolysis In this method, iron is extracted from its electrolyte solution, resulting in high-purity iron powder. The electrolysis process is often used when higher purity is required for specialized applications.

3. Mechanical Milling In this approach, bulk iron is mechanically ground into a fine powder. While the purity may be lower than that obtained through chemical methods, milling can produce a range of particle sizes tailored for specific applications.

Applications of Pure Iron Powder

pure iron powder

Pure iron powder has a wide range of applications across different industries due to its unique physical and chemical properties. Some notable applications include

1. Magnetic Materials Pure iron powder is widely used in the production of magnetic cores for transformers, inductors, and electric motors. The superior magnetic properties of pure iron enhance the efficiency and effectiveness of these components, making them essential in electronics.

2. Additive Manufacturing In the field of 3D printing, pure iron powder is used as a feedstock for producing intricate components through selective laser sintering (SLS) and other additive manufacturing techniques. The fine particle size allows for detailed designs and complex geometries that would be difficult to achieve through traditional methods.

3. Metal Injection Molding (MIM) This process uses a mixture of metal powder and a polymer binder to produce complex shapes with high precision. Pure iron powder is a preferred material in MIM due to its ability to achieve tight tolerances and excellent mechanical properties.

4. Catalysts and Chemical Reactions Pure iron powder is also utilized as a catalyst in various chemical reactions, including the production of ammonia in the Haber process. Its high surface area increases the reaction rates, making the process more efficient.

5. Biomedical Applications In the biomedical field, pure iron powder is explored for use in implants and drug delivery systems. Due to its biocompatibility and ability to be absorbed by the body, it holds promise for various medical applications.

6. Batteries and Energy Storage Recent research has highlighted the potential of pure iron powder in energy storage applications, particularly in battery technologies. Its affordability and abundance could lead to the development of more sustainable energy solutions.

Conclusion

Pure iron powder is a remarkable material encompassed in a variety of industrial applications, thanks to its superior properties. From magnetic materials to advanced manufacturing techniques, its versatility is paving the way for innovative solutions across multiple sectors. As technology continues to evolve, the demand for pure iron powder is expected to grow, highlighting its importance in the development of new materials and products. Ongoing research into its applications and production methods will undoubtedly unlock further potential, making pure iron powder a vital component in the future of engineering and technology.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025