pure calcium carbonate powder factories

The Role and Importance of Pure Calcium Carbonate Powder Factories

Calcium carbonate (CaCO3) is a naturally occurring mineral that has become a vital ingredient in various industries, including construction, pharmaceuticals, food and beverages, and plastic manufacturing. Its versatility stems from its unique properties, such as high purity, low cost, and excellent performance as a filler and coating agent. Pure calcium carbonate powder factories play a crucial role in manufacturing high-quality products that meet the growing demands of various sectors.

Understanding Calcium Carbonate

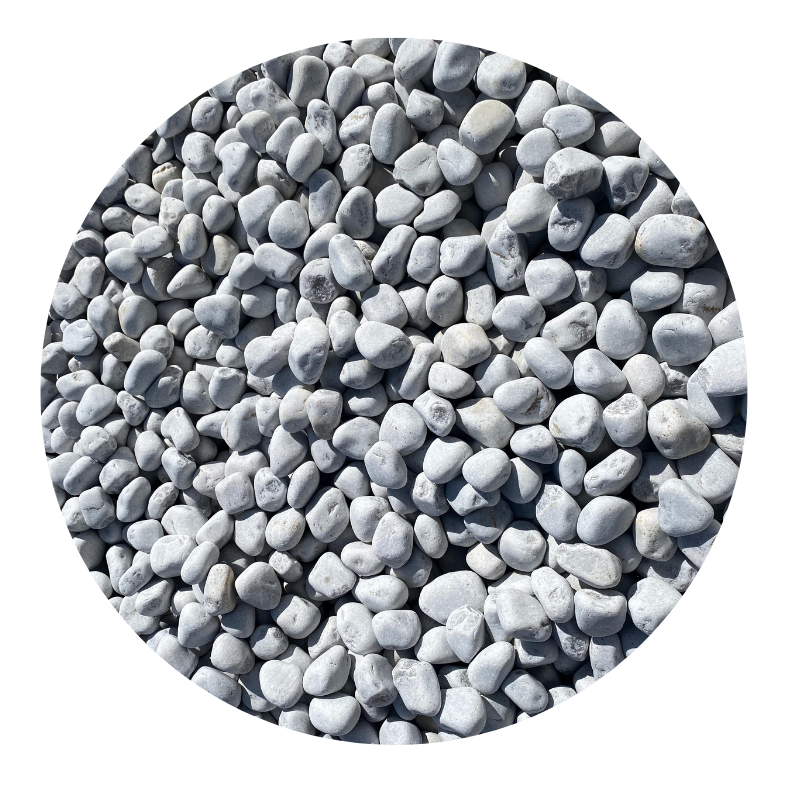

Calcium carbonate is found in rocks in the form of minerals like limestone, marble, and chalk. It is a white, odorless powder that is insoluble in water, but soluble in acids. When heated, it decomposes into calcium oxide (lime) and carbon dioxide, making it an essential compound in construction and manufacturing processes.

The purity of calcium carbonate is significant in determining its applicability in industrial uses. Pure calcium carbonate typically boasts a purity of 98% or higher, ensuring that it meets the stringent quality standards required by various industries. Factories that produce pure calcium carbonate powder implement strict quality control measures to ensure that the product remains free from contaminants.

Key Processes in Calcium Carbonate Production

The production of pure calcium carbonate powder involves several key processes. The first step is the extraction of raw materials from quarries. The extracted limestone undergoes crushing and grinding to reduce it to a desired particle size.

Next, the powdered limestone is subjected to a calcination process in which it is heated in a kiln. This step not only purifies the material but also helps in producing a specific form of calcium carbonate, such as precipitated calcium carbonate (PCC) or ground calcium carbonate (GCC). PCC is produced through a chemical process involving carbon dioxide and lime, resulting in a product with high purity and controlled particle size.

pure calcium carbonate powder factories

Once the desired form of calcium carbonate is produced, it undergoes further processing to ensure it meets industry-specific standards

. This may include surface treatment, classification, and packaging, during which quality assurance measures are taken to ensure that the final product is free from impurities and meets customer specifications.Applications of Pure Calcium Carbonate Powder

The applications of pure calcium carbonate powder are vast and diverse. In the construction industry, it is used as a vital ingredient in cement and concrete production, providing strength and durability to structures. It is also used as a filler in paints, coatings, and plastics, improving their texture and performance while reducing production costs.

In the pharmaceutical and food industries, pure calcium carbonate is valued for its calcium content and is used as a dietary supplement. It acts as an antacid, relieving symptoms of indigestion and heartburn. Additionally, its white color and fine texture make it an excellent food additive for various products, including bakery goods and dairy items.

Moreover, the environmental impact of calcium carbonate should not be overlooked. Pure calcium carbonate can be utilized in carbon capture technologies, making it instrumental in the fight against climate change. It can absorb carbon dioxide emissions, helping industries transition to more sustainable practices.

The Future of Calcium Carbonate Factories

As industrial applications for pure calcium carbonate continue to grow, so too does the need for efficient and sustainable production. Factories are increasingly adopting advanced technologies to enhance production processes, reduce energy consumption, and minimize waste. Research into new applications and the development of innovative products based on calcium carbonate is also on the rise, pointing towards a promising future.

In conclusion, pure calcium carbonate powder factories are integral to numerous industries, providing high-quality materials essential for a range of applications. As the demand for pure calcium carbonate continues to increase, these factories are expected to play an even more significant role in shaping sustainable industrial practices and fulfilling the needs of a rapidly evolving market.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025