pelletized activated carbon manufacturers

Pelletized Activated Carbon Manufacturers A Deep Dive into the Industry

In the realm of environmental management and pollution control, activated carbon plays a crucial role due to its unparalleled adsorption capabilities. Among the various forms of activated carbon, pelletized activated carbon (PAC) has emerged as a favorable choice for many applications, including water and air purification, industrial processes, and even in food and beverage industries. This article discusses the manufacturers of pelletized activated carbon, highlighting their importance, production processes, and the applications of their products.

Understanding Pelletized Activated Carbon

Pelletized activated carbon is produced from various carbonaceous materials, such as coconut shells, coal, or peat, which undergoes a rigorous activation process. The result is a highly porous structure with a large surface area, which efficiently traps impurities from gases and liquids. The pelletized form offers additional benefits, including reduced dust generation and improved handling characteristics, making it easier to transport and use in different systems.

The Role of Manufacturers

Manufacturers of pelletized activated carbon are pivotal in ensuring the availability and quality of this essential material. Various companies specialize in the production of PAC, often tailoring their products to meet specific client needs across different industries. These manufacturers adopt advanced technologies to enhance the performance and effectiveness of their activated carbon offerings.

Production Processes

The manufacturing process of pelletized activated carbon typically involves several stages

1. Raw Material Selection The first step involves choosing the right raw materials. Coconut shells are often preferred due to their high carbon content and sustainability. Other sources include bituminous coal and lignite.

2. Carbonization The selected material is subjected to carbonization at high temperatures (around 600-1200°C) in an inert atmosphere. This process removes volatile organic compounds and creates a char structure that is crucial for activation.

3. Activation There are two primary activation methods physical and chemical. Physical activation involves treating the carbonized material with steam or carbon dioxide at high temperatures, while chemical activation uses chemicals like phosphoric acid or potassium hydroxide. This step significantly increases the surface area and porosity of the carbon.

4. Pelletization After activation, the activated carbon is ground into fine particles and then compressed into pellets. This form facilitates handling and enhances performance in adsorption applications.

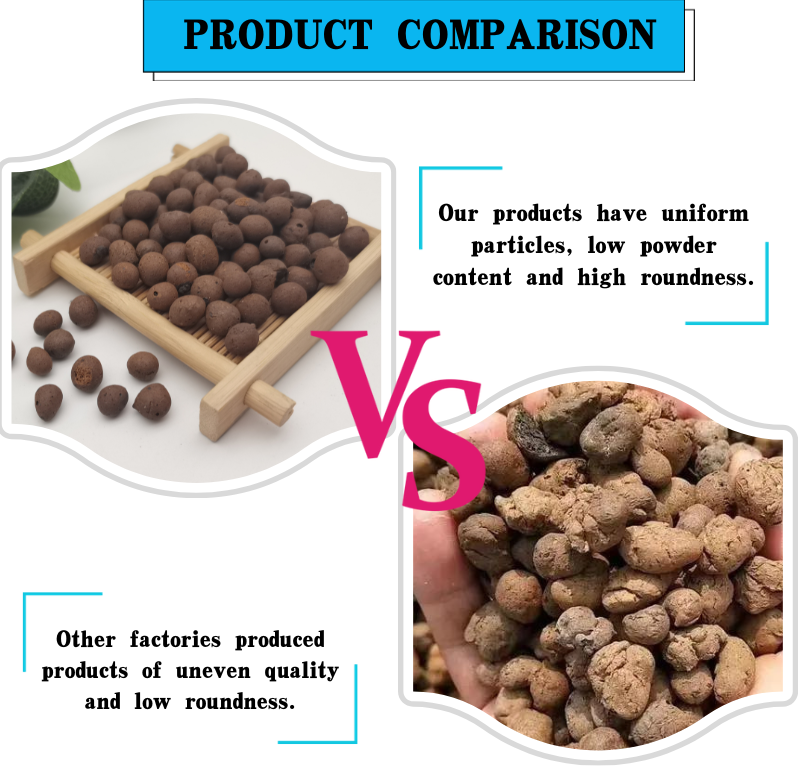

5. Quality Control Manufacturers conduct rigorous quality checks to ensure that the final product meets industry standards and customer specifications. This includes testing for surface area, pore volume, and mechanical strength.

pelletized activated carbon manufacturers

Applications of Pelletized Activated Carbon

The versatility of pelletized activated carbon allows it to be used across various sectors

- Water Treatment PAC is commonly used in municipal and industrial water treatment plants for contaminant removal, taste and odor control, and compliance with environmental regulations.

- Air Purification In industrial settings, PAC is utilized in scrubbers and filters to capture volatile organic compounds (VOCs), odors, and other airborne pollutants.

- Food and Beverage Industry Pelletized activated carbon is employed in sugar refining and alcohol production to eliminate impurities and improve the color and clarity of the final product.

- Pharmaceuticals The pharmaceutical industry uses PAC for purification processes, ensuring the removal of unwanted by-products and contaminants from drugs.

- Automotive The automotive industry employs PAC in cabin air filters to enhance passenger comfort by removing harmful gases and odors.

Challenges and Future Trends

While the market for pelletized activated carbon is growing, manufacturers face several challenges. These include the need for sustainable sourcing of raw materials, compliance with stringent environmental regulations, and the constant demand for product innovation to meet diverse customer requirements.

Looking forward, manufacturers are increasingly focusing on developing eco-friendly production methods and exploring new applications for PAC. Innovations such as the integration of nanotechnology and the development of composite materials that incorporate activated carbon are on the rise. These advancements could open new avenues in air and water treatment, filtration, and beyond.

Conclusion

Pelletized activated carbon manufacturers play an essential role in supplying this critical material for a wide range of applications. Through innovative production techniques and strict quality control, these manufacturers ensure that their products meet the evolving demands of industries worldwide. As environmental concerns continue to grow, the significance of pelletized activated carbon in pollution control and resource management will likely expand, heralding a new era of cleaner air and water.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025