oem silica fume in cement factory

The Role of OEM Silica Fume in Cement Factories

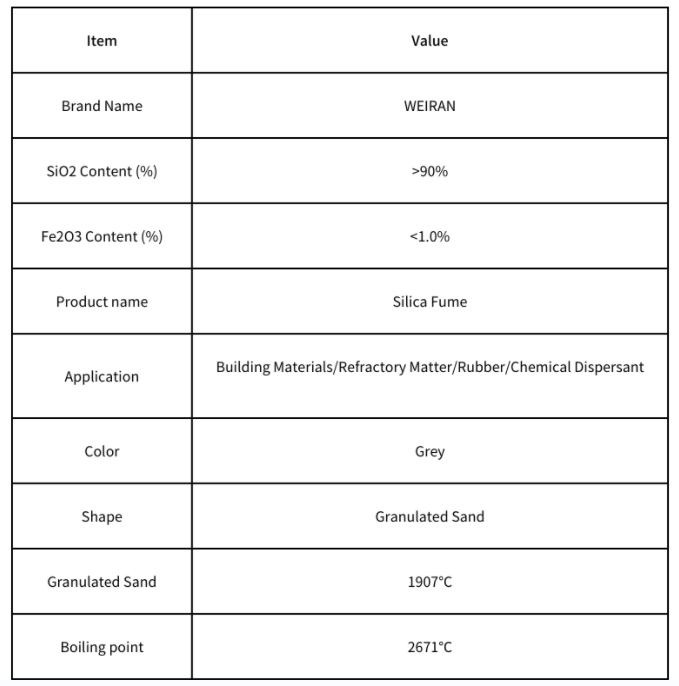

Silica fume, a byproduct of silicon metal production, has garnered considerable attention in the construction industry, particularly in cement manufacturing. This fine, amorphous powder is known for its unique properties that enhance the performance of concrete. As the construction sector continues to evolve, the demand for high-quality concrete has skyrocketed, leading to an increased adoption of silica fume by Original Equipment Manufacturers (OEMs) in cement factories.

The Role of OEM Silica Fume in Cement Factories

Moreover, silica fume contributes to improved workability and reduced permeability. By providing a smoother consistency, the incorporation of silica fume allows for easier placement and finishing of concrete. Simultaneously, it lowers the ingress of harmful substances such as water, chloride ions, and sulfates, which can lead to corrosion and degradation of concrete structures over time. This characteristic is essential for infrastructure exposed to harsh environmental conditions, including bridges, highways, and marine structures.

oem silica fume in cement factory

Another significant benefit of using silica fume in cement factories is its positive environmental impact. The cement industry is one of the largest contributors to CO2 emissions, accounting for approximately 7% of global emissions. By replacing a portion of ordinary Portland cement (OPC) with silica fume, the carbon footprint of concrete production can be significantly reduced. OEMs are increasingly focusing on sustainable practices and utilizing silica fume aligns well with these efforts, contributing to greener construction methods.

In addition to its technical benefits, the use of silica fume can also lead to cost savings for cement factories. Though the initial investment may seem high, the long-term advantages, such as reduced maintenance costs and increased service life of structures, can outweigh the initial expenditure. Furthermore, the enhanced performance characteristics can allow construction companies to use less material without compromising quality, ultimately resulting in economic savings.

As the demand for sustainable and high-performance concrete continues to rise, OEM silica fume will likely play an increasingly vital role in cement factories worldwide. Cement manufacturers are encouraged to embrace this innovative ingredient, not only to enhance the quality of their products but also to contribute to a more sustainable construction industry. In conclusion, OEM silica fume stands out as an essential material that can transform the landscape of cement production, aligning performance with environmental responsibility in modern construction practices.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025