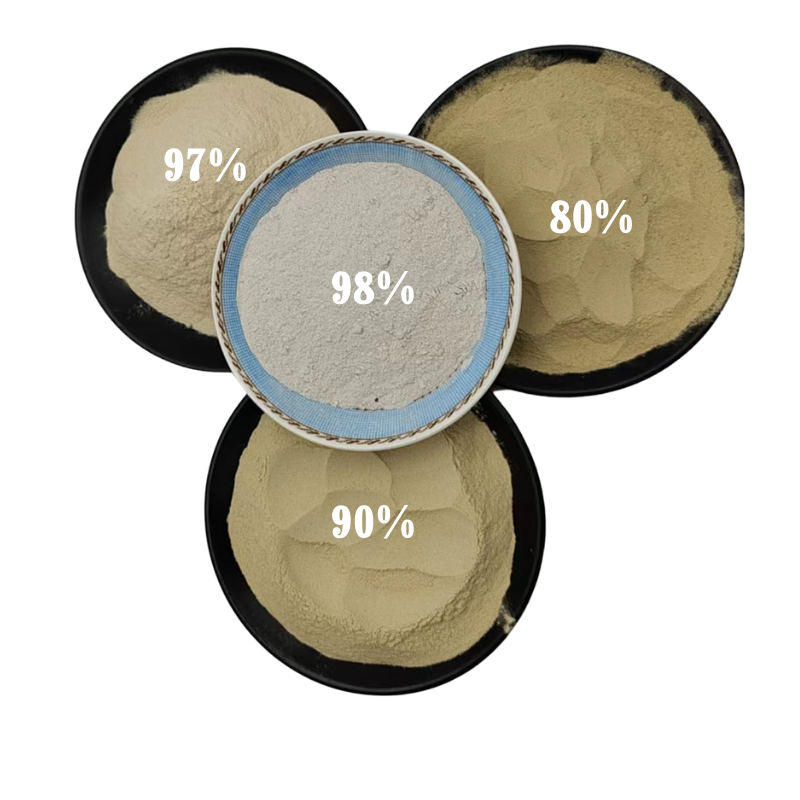

oem silica fume fly ash manufacturer

The Role of OEM Silica Fume and Fly Ash in Modern Construction

In the ever-evolving landscape of construction materials, OEM silica fume and fly ash have emerged as pivotal components, reshaping how concrete is produced and utilized. These materials are not just additives; they play a significant role in enhancing the properties of concrete, contributing to sustainability, and improving the overall performance of structures.

Understanding Silica Fume and Fly Ash

Silica fume, a byproduct of silicon and ferrosilicon alloy production, is composed of very fine particles that can significantly improve the properties of concrete. It is known for its pozzolanic properties, meaning that when mixed with water and calcium hydroxide, it reacts to form compounds that contribute to the strength and durability of concrete. This fine powder can fill voids in the concrete matrix, resulting in a denser, stronger end product.

On the other hand, fly ash is a byproduct of burning pulverized coal in electric power generating plants. It is a versatile material that can be categorized into Class F and Class C fly ash, each with different chemical compositions and properties. Class F fly ash, for instance, is rich in silica and alumina, making it an excellent pozzolanic material. Class C fly ash contains calcium oxide, which can react with water to form cementitious compounds.

Benefits of Using Silica Fume and Fly Ash

1. Enhanced Mechanical Properties

The incorporation of silica fume and fly ash in concrete greatly enhances its mechanical properties. Silica fume contributes to increased compressive strength, flexural strength, and tensile strength. When used together, these materials can create high-performance concrete capable of withstanding extreme conditions, making them suitable for bridges, highways, and other infrastructural developments.

2. Improved Durability

oem silica fume fly ash manufacturer

One of the most significant advantages of using silica fume and fly ash is the improvement in durability. These materials enhance the resistance of concrete to various forms of degradation, including sulfate attack, chloride ion penetration, and alkali-silica reaction. This leads to longer-lasting structures, reduced maintenance costs, and increased safety for users.

3. Sustainability Advantages

In an age where sustainability is paramount, the use of silica fume and fly ash in concrete production promotes green building practices. By utilizing industrial byproducts, these materials reduce the need for virgin materials, minimizing environmental impact. Additionally, the energy required to produce traditional cement is significant, but by replacing a portion of the cement with these pozzolanic materials, the carbon footprint of concrete can be substantially lowered.

4. Cost-Effectiveness

Using OEM silica fume and fly ash can also lead to cost savings in construction projects. The reduction in the amount of cement required not only lowers material costs but also can result in reduced transportation expenses. Moreover, the improved properties of concrete can lead to longer service life and lower lifecycle costs.

The Role of Manufacturers

OEM manufacturers specializing in silica fume and fly ash play a crucial role in this process. They ensure the quality and consistency of these materials, which is essential for maintaining the performance standards expected in modern construction. These manufacturers often invest in research and development to innovate and improve the materials, ensuring they meet the ever-growing demands of the construction industry.

Conclusion

The introduction of OEM silica fume and fly ash marks a significant milestone in the construction sector. Their ability to enhance the strength and durability of concrete while promoting sustainability positions them as vital components in modern construction practices. As the industry continues to evolve, it is clear that the integration of these materials will play a fundamental role in building resilient structures that meet the demands of the future while minimizing environmental impact. Through the commitment of manufacturers to produce high-quality silica fume and fly ash, the construction industry is set to achieve remarkable advancements in material science, sustainability, and structural performance.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025