OEM Real Glass Beads Manufacturer for High-Quality Decorative Applications and Industrial Uses

OEM Real Glass Beads Factory Crafting Excellence in Every Bead

In today’s dynamic market, the demand for high-quality glass beads has surged across various industries, including fashion, decoration, and handicrafts. One of the key players meeting this demand is OEM (Original Equipment Manufacturer) real glass beads factories, which specialize in producing top-notch glass beads tailored to the specific needs of their clients. This article explores the significance of OEM real glass beads factories, their production processes, and the benefits they offer to businesses and artisans alike.

Understanding OEM in Glass Bead Manufacturing

OEM refers to companies that manufacture products based on the specifications provided by another company. In the context of glass beads, OEM factories create bespoke beads that meet the unique design requirements of their clients. This ability to customize products makes OEM factories an attractive option for brands looking to differentiate themselves in a competitive marketplace.

The Production Process

The process of manufacturing real glass beads involves several meticulous steps. Firstly, the selection of raw materials is crucial. High-quality glass, often sourced from reliable suppliers, is blended with various additives to achieve the desired color, durability, and finish. The glass mixture is then heated to extremely high temperatures in a furnace, transforming it into a molten state.

Once the glass is molten, skilled artisans or advanced machinery shape the beads. This can be done in several ways, including hand-rolling and molding. The consistency in size and shape is imperative, especially for applications in jewelry and decorative items where uniformity is key. After shaping, the beads are cooled in a controlled environment to prevent cracking and preserve their integrity.

Once cooled, the beads undergo a series of finishing processes. This may include polishing, coating, or adding intricate designs. These finishing touches not only enhance the aesthetic appeal of the beads but also ensure they meet the specific standards demanded by clients. The final stages of production involve thorough quality control checks to guarantee that only the best products reach the market.

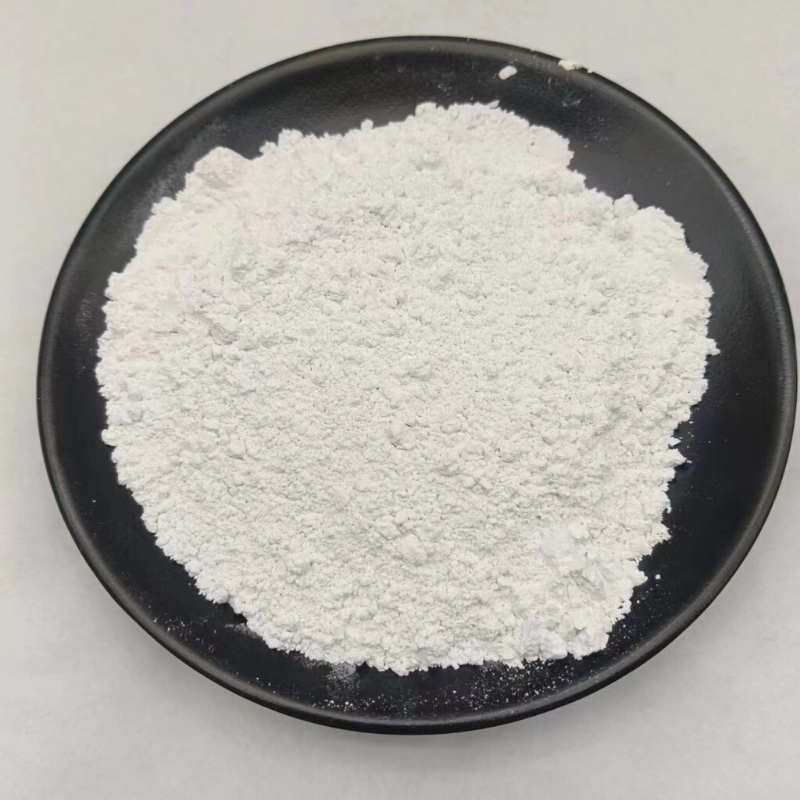

oem real glass beads factory

Benefits of Partnering with OEM Real Glass Beads Factories

1. Customization and Flexibility One of the most significant benefits of working with an OEM factory is the ability to customize. Clients can specify everything from color and size to the intricacy of designs. This level of customization helps brands create unique product lines that appeal to specific target markets.

2. Cost-Effectiveness OEM factories often have well-established supply chains and production processes, which can lead to lower manufacturing costs. By partnering with an OEM, brands can reduce their overheads, pass on savings to customers, and ultimately increase their profit margins.

3. Quality Assurance Reputable OEM factories prioritize quality control. With strict procedures in place, clients can be assured that the products will meet their standards. This is critical in industries where quality can directly impact brand reputation.

4. Scalability For businesses looking to grow, partnering with an OEM factory provides the operational flexibility required to scale production up or down based on demand. Whether launching a new product line or responding to market trends, OEM factories can adjust production schedules to meet changing needs.

5. Access to Expertise Many OEM manufacturers possess extensive knowledge and experience in glass bead production. This expertise can be invaluable for clients looking to innovate or develop new products. Collaborating with a knowledgeable partner can streamline the design process and lead to better outcomes.

Conclusion

In an era where personalization and quality are paramount, OEM real glass beads factories emerge as essential partners for businesses across various sectors. Their ability to provide customized, high-quality glass beads while maintaining cost-effectiveness and scalability positions them as leaders in the market. As the demand for unique and aesthetically pleasing products continues to rise, these factories are likely to play an increasingly important role in meeting consumer needs and shaping industry trends. Whether for jewelry-making, crafts, or decor, OEM glass beads are a testament to craftsmanship and innovation, ensuring that every bead adds value to creations across the globe.

Share

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025