oem perlite concrete

The Use and Advantages of OEM Perlite Concrete

Perlite concrete, a lightweight and versatile construction material, has garnered significant attention in modern building practices. Often utilized for its superior insulation properties and low density, perlite concrete is composed of perlite aggregate, which is a volcanic glass that expands when heated. One of the foremost methodologies in producing such innovative materials is through Original Equipment Manufacturer (OEM) partnerships, which streamline the manufacturing process. This article delves into the characteristics, benefits, and applications of OEM perlite concrete.

Understanding Perlite Concrete

Perlite is a naturally occurring siliceous volcanic rock that, when heated to high temperatures, expands into small, lightweight aggregates. When combined with cement and water, it forms a type of concrete that is not only light but also offers exceptional thermal and acoustic insulation properties. The inherent porosity of perlite contributes to its thermal performance, making perlite concrete an excellent choice for energy-efficient building designs.

The Role of OEM in Perlite Concrete Production

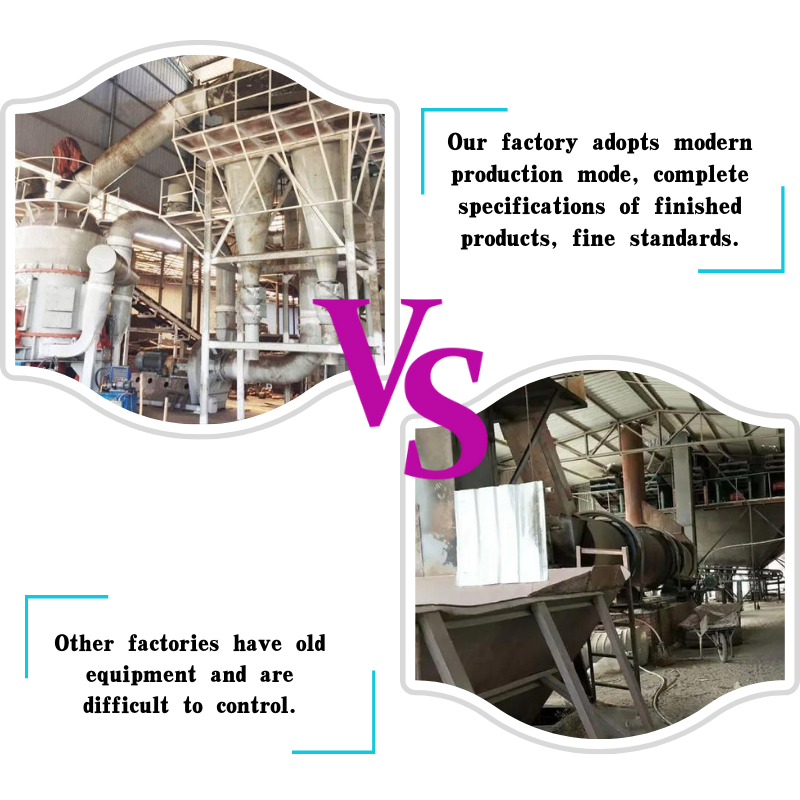

OEMs play a critical role in the production of perlite concrete. By partnering with specialized manufacturers, companies can acquire high-quality perlite aggregates that meet specific standards. This collaboration ensures consistency in material properties and performance, which is vital for commercial applications. Furthermore, OEM relationships facilitate innovation within the construction sector, allowing for the development of new formulations and products that can meet the evolving demands of the market.

Benefits of OEM Perlite Concrete

1. Lightweight Nature One of the primary advantages of perlite concrete is its lightweight characteristic. This feature significantly reduces the overall weight of structures, making it easier to handle during construction and requiring less foundational support. This lightweight aspect allows for more flexible design options and potential cost savings on materials.

2. Excellent Insulation Perlite concrete has been shown to provide superior thermal insulation compared to traditional concrete. The air pockets within the perlite aggregate effectively reduce heat transfer, resulting in energy savings for heating and cooling systems in buildings. This energy efficiency is not only beneficial for occupants' comfort but also aligns with sustainable building practices.

oem perlite concrete

3. Fire Resistance Given its inorganic composition, perlite concrete exhibits fire-resistant properties. This makes it an ideal choice for applications that demand fire safety, such as in commercial buildings, high-rise structures, and residential developments. The use of fire-resistant materials can potentially lower insurance premiums and enhance the overall safety of the design.

4. Sound Absorption The porous nature of perlite also provides excellent sound absorption capabilities. Structures built with perlite concrete can achieve enhanced acoustic performance, which is particularly advantageous in urban areas where noise control is paramount. This application is ideal for residential buildings, theaters, and offices requiring peaceful environments.

5. Eco-friendliness As awareness of environmental issues grows, perlite concrete stands out as an environmentally sustainable option. The use of volcanic ash and the lightweight nature of the material contribute to reduced carbon footprints. Additionally, the energy efficiency of perlite concrete helps lessen reliance on fossil fuels for heating and cooling.

Applications of OEM Perlite Concrete

The versatility of OEM perlite concrete allows it to be utilized in a variety of applications. Common uses include

- Roofing Systems Its lightweight and insulation properties make perlite concrete ideal for roofing applications, helping to reduce energy costs and providing effective drainage. - Walls and Partitions The combination of structural integrity and sound insulation makes perlite concrete an excellent choice for interior and exterior wall systems. - Floors Used as a topping layer, perlite concrete can create a resilient floor surface that is both lightweight and thermally efficient. - Precast and Cast-in-Place Structures Perlite concrete can be employed in both precast elements and cast-in-place construction due to its adaptability and ease of use.

Conclusion

In conclusion, OEM perlite concrete represents a significant advancement in building materials, offering numerous benefits from its lightweight nature to impressive insulation properties. By leveraging OEM partnerships, builders can ensure the quality and consistency of perlite concrete, paving the way for innovative construction practices that prioritize sustainability and efficiency. As the demand for energy-efficient and environmentally-friendly materials continues to grow, perlite concrete stands as a promising option for the future of construction.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025