OEM Suppliers of Natural Zeolite Powder for Various Applications and Industries

The Rise of OEM Natural Zeolite Powder Manufacturers

In recent years, the demand for natural zeolite powder has surged, primarily due to its diverse applications across various industries. Natural zeolites are porous, crystalline aluminosilicates that are found in nature. Their unique properties, such as ion exchange capabilities, adsorption, and molecular sieving, make them suitable for industries ranging from agriculture to wastewater treatment. As a result, Original Equipment Manufacturer (OEM) natural zeolite powder manufacturers have become increasingly significant players in this market.

The Importance of Natural Zeolite

Natural zeolite has been recognized for its environmental benefits and efficiency in several applications. In agriculture, for instance, zeolite's ability to retain moisture and improve nutrient exchange in soils has led to enhanced crop yields. Farmers worldwide are utilizing zeolite as a soil amendment to reduce fertilizer usage, ultimately leading to a more sustainable and eco-friendly approach to farming.

In water treatment, natural zeolite is used for its ion exchange properties, effectively removing heavy metals and other contaminants from wastewater. Its application in treating drinking water has also gained traction, as zeolite can filter out harmful substances, ensuring safe water for communities. Moreover, the animal husbandry sector is leveraging natural zeolite to improve feed quality and enhance the health of livestock, which underscores its vast utility.

The Role of OEM Manufacturers

The rise of OEM manufacturers in the natural zeolite powder industry plays a crucial role in meeting the burgeoning demand. These manufacturers focus on producing high-quality zeolite powder tailored to the specific needs of their clients. By offering customization options, they enable businesses across different sectors to utilize zeolite in a way that best suits their applications.

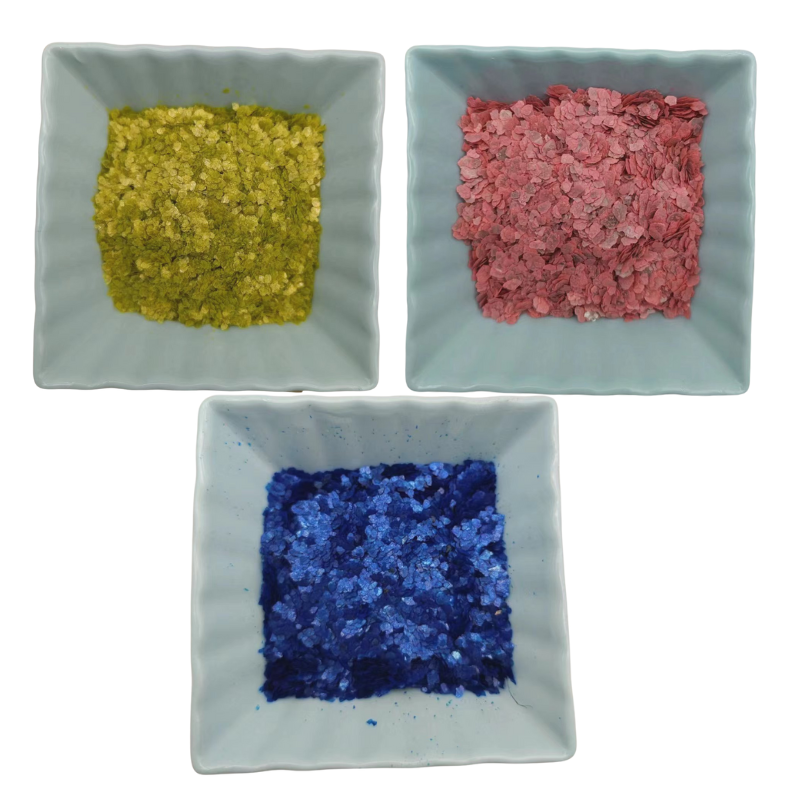

OEM manufacturers typically engage in sourcing raw natural zeolite from mines, processing it through grinding and sieving, and then providing it in various particle sizes and purities. This versatility allows companies to incorporate zeolite powder into their products seamlessly. For instance, industries can use zeolite in fertilizers, water filtration systems, or even in cosmetics, thereby expanding its application potential.

oem natural zeolite powder manufacturers

Sustainable Production Practices

With the increasing awareness of environmental issues, many OEM natural zeolite manufacturers are adopting sustainable production practices. This shift is vital, as the extraction of natural zeolites can have ecological impacts if not managed responsibly. Modern manufacturers are now focusing on sustainable mining techniques that minimize disruption to the surrounding ecosystem and ensure that resources are harvested efficiently.

Furthermore, these manufacturers are increasingly committed to reducing their carbon footprint by incorporating renewable energy sources and employing eco-friendly technologies in their production processes. This commitment not only enhances their marketability but also resonates with environmentally-conscious consumers who prefer products with a smaller ecological impact.

Challenges and Opportunities Ahead

Despite the promising growth of the natural zeolite powder industry, OEM manufacturers face several challenges. Global supply chain disruptions, fluctuating raw material prices, and competition from synthetic alternatives pose threats to market stability. Nevertheless, these challenges also bring opportunities. As industries continue to seek natural solutions for their needs, the adaptability and proven efficacy of natural zeolite position it as a favorable option against synthetic counterparts.

Moreover, with ongoing research dedicated to exploring new applications of natural zeolite, manufacturers who invest in innovation and product development can stay ahead. Potential markets include the pharmaceutical industry, where zeolite’s properties may be harnessed in drug delivery systems or as a component in medical applications.

Conclusion

In conclusion, the landscape of OEM natural zeolite powder manufacturers is evolving rapidly, driven by the increasing demand for sustainable and efficient solutions across various industries. By focusing on quality production, customization, and environmentally-friendly practices, these manufacturers contribute significantly to the growth and application of natural zeolite powder in modern society. As challenges persist, the horizon remains bright for those willing to innovate and adapt in this dynamic marketplace.

Share

-

Premium Ceramsite for Plants & Hydroponics - Ideal Growing MediaNewsAug.10,2025

-

Premium Mineral Sepiolite Powder: Versatile Adsorbent & FillerNewsAug.09,2025

-

Premium Talcum Powder - Smoothness & Purity GuaranteedNewsAug.08,2025

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025