oem natural dolomite powder factories

Understanding OEM Natural Dolomite Powder Factories

In recent years, the demand for natural dolomite powder has surged, driven by its versatile applications across various industries, including agriculture, construction, and manufacturing. Operating as Original Equipment Manufacturer (OEM) factories, producers of dolomite powder play a vital role in supplying this essential mineral in a format tailored to specific customer requirements. This article delves into the significance, processes, and benefits of OEM natural dolomite powder factories.

What is Dolomite Powder?

Dolomite is a calcium magnesium carbonate mineral that in its powdered form, serves as a critical component in numerous industrial applications. It boasts remarkable physical and chemical properties, such as high purity levels, low iron content, and excellent particle size distribution. These characteristics make dolomite powder suitable for use in the production of ceramics, glass, fertilizers, and as a filler in plastics, paints, and more.

The Role of OEM in Dolomite Production

OEM factories specialize in producing products that are branded and sold by other companies. In the context of dolomite powder, these factories provide custom solutions that can meet specific client specifications regarding particle size, purity levels, and packaging formats. This flexibility allows businesses to leverage expert manufacturing services while focusing on their core competencies.

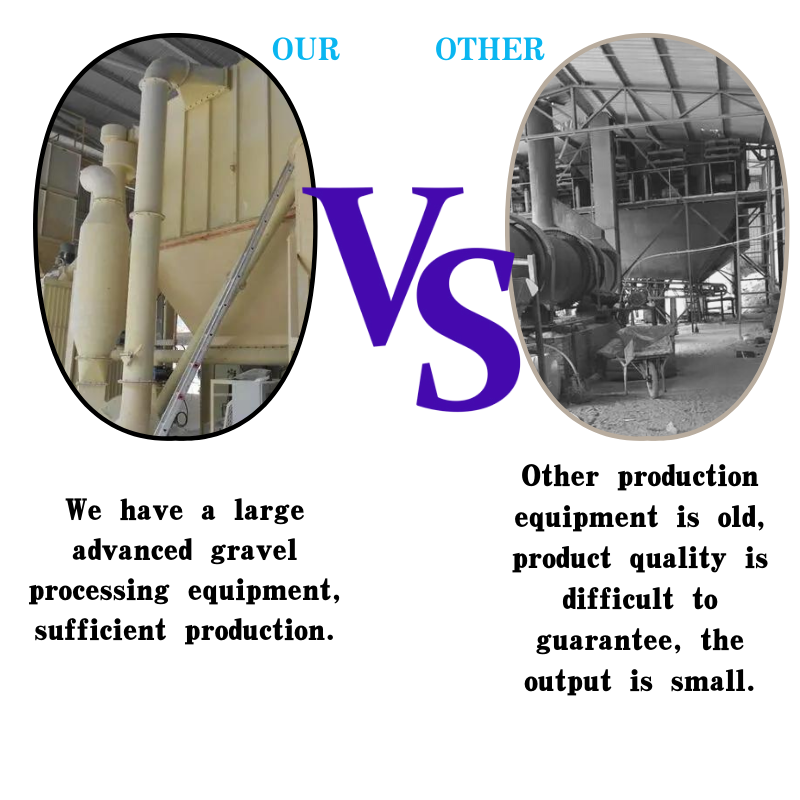

By partnering with OEM natural dolomite powder factories, companies can benefit from reduced production costs, improved product quality, and access to advanced technology that they might not have in-house. Additionally, OEM manufacturers often possess industry certifications, ensuring that their products meet regulatory standards and are safe for various applications.

Manufacturing Process of Dolomite Powder

The manufacturing process of dolomite powder typically involves several key steps

1. Mining The first step involves the extraction of dolomite from quarries or mines. This raw material contains both calcium and magnesium carbonate, which are crucial for producing high-quality dolomite powder.

2. Crushing Once mined, the dolomite rocks are crushed into smaller pieces using crushers. This step increases the surface area of the material and prepares it for the grinding process.

oem natural dolomite powder factories

3. Grinding The crushed dolomite is then finely ground using various types of mills, such as ball mills or Raymond mills. The goal during this phase is to achieve a specific fineness that meets customer specifications.

4. Classifying After grinding, the dolomite powder is classified based on particle size using air classifiers. This step ensures that the final product is sorted according to the varying size requirements of different industries.

5. Packaging Finally, the dolomite powder is packaged in appropriate bags or containers to facilitate transportation and maintain product integrity.

Applications of Dolomite Powder

The versatility of natural dolomite powder allows it to be used in numerous applications, including

- Agriculture Dolomite powder is an excellent soil conditioner, helping to correct soil acidity and providing essential nutrients to crops. - Construction In construction, it serves as an aggregate in concrete and asphalt, enhancing the material's strength and durability. - Chemicals The powder is also used in the production of glass and ceramics, acting as a flux to lower the melting point of raw materials. - Filler Material Industries such as plastics, paints, and rubber utilize dolomite powder as a filler, improving product attributes like texture and stability.

Benefits of Sourcing from OEM Factories

By choosing to source dolomite powder from OEM factories, businesses can experience several advantages

- Customization OEM manufacturers offer tailor-made solutions, ensuring the dolomite powder aligns perfectly with the specific needs of the customer. - Quality Assurance OEM factories typically implement stringent quality control measures, ensuring that all products comply with industry standards. - Cost Efficiency By outsourcing production to OEM facilities, companies can minimize capital investments and operational costs, ultimately increasing profitability.

Conclusion

The importance of OEM natural dolomite powder factories in today’s market cannot be overstated. Their ability to produce high-quality, customized dolomite powder is crucial for various industries that depend on this versatile mineral. As businesses continue to seek out innovative and cost-effective solutions, partnering with OEM manufacturers may prove to be a strategic move that fosters growth and enhances product offerings in the competitive marketplace. With a thorough understanding of dolomite powder production, companies can effectively meet customer demands and thrive in their respective industries.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025