Top Metakaolin Suppliers for OEM Applications and Innovative Manufacturing Solutions

The Rising Demand for OEM Metakaolin Manufacturers

In recent years, the construction industry has undergone significant transformation, driven by the need for more sustainable and efficient building materials. One of the materials that have gained prominence is metakaolin, a high-performative pozzolanic material derived from kaolinite clay through a calcination process. As the demand for this innovative material grows, the role of Original Equipment Manufacturer (OEM) metakaolin manufacturers becomes increasingly critical.

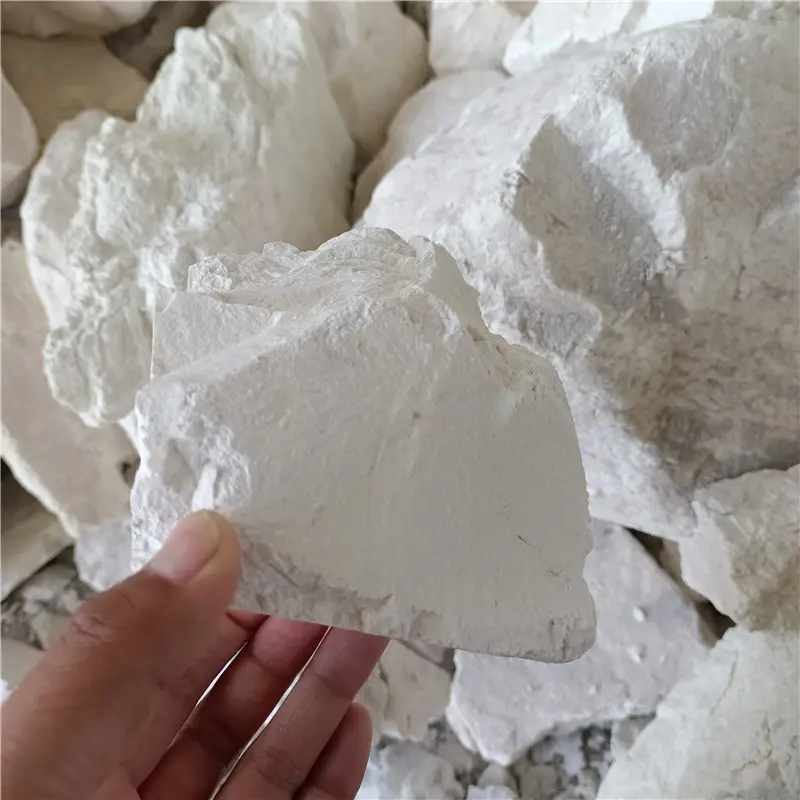

Understanding Metakaolin

Metakaolin is created by heating kaolin clay to temperatures between 600°C and 800°C. This process dehydroxylates the clay, resulting in a highly reactive aluminosilicate compound. The unique properties of metakaolin, including its fine particle size, white color, and pozzolanic behavior, make it a valuable additive in cement, concrete, and various building products. It helps improve the mechanical properties of concrete, enhances workability, and reduces permeability, leading to longer-lasting structures.

The Role of OEM Manufacturers

OEM metakaolin manufacturers play a pivotal role in the market by producing customized products tailored to the specific needs of their clients. These manufacturers work closely with construction companies, engineers, and architects to develop metakaolin that meets stringent quality standards and performance criteria. The collaboration allows for the optimization of material properties for various applications, from residential buildings to large-scale infrastructure projects.

Advantages of OEM Metakaolin

1. Customization OEM manufacturers can produce metakaolin with specific physical and chemical properties, allowing for better integration with different types of cement and concrete mixes. This customization helps clients achieve desired performance metrics, such as strength and durability.

oem metakaolin manufacturers

2. Quality Control By leveraging advanced technology and dedicated production processes, OEM manufacturers ensure that their metakaolin consistently meets high-quality standards. This quality assurance is crucial, as any inconsistencies in material performance can lead to structural failures.

3. Supply Chain Efficiency Having a reliable OEM partner can streamline the supply chain for construction projects. OEM manufacturers are often capable of large-volume production, which helps maintain a steady supply of metakaolin, reducing delays and ensuring that builders have access to the necessary materials when needed.

4. Sustainability As the construction industry increasingly adopts green building practices, metakaolin's low environmental impact makes it an attractive option. OEM manufacturers often implement eco-friendly practices in their production processes, thus further promoting sustainability within the industry.

5. Research and Innovation Many OEM metakaolin manufacturers are involved in ongoing research and development to innovate new products and applications. This commitment to innovation not only enhances the performance of metakaolin but also expands its use in various sectors, including road construction, precast concrete products, and more.

The Future of OEM Metakaolin Manufacturers

As the global construction market evolves, the future of OEM metakaolin manufacturers appears bright. The growing emphasis on sustainable construction and the demand for high-performance materials position metakaolin at the forefront of innovation. Additionally, as more countries prioritize infrastructure development, the need for reliable and high-quality metakaolin will only continue to rise.

In conclusion, OEM metakaolin manufacturers are integral to the future of sustainable building practices. They provide essential products that enhance the quality and longevity of construction materials, thereby contributing to the development of resilient infrastructure. As the industry progresses, the synergy between metakaolin manufacturers and construction professionals will play a crucial role in shaping the future of building technology.

Share

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025