oem loi fly ash factory

The Role of OEM in the Fly Ash Industry Exploring Opportunities for Sustainable Development

In recent years, the construction and building materials industry has undergone significant transformation, with a growing emphasis on sustainability and eco-friendly practices. One of the key players in this arena is fly ash, a byproduct of coal combustion in power plants, which has emerged as a valuable resource in the production of concrete and other building materials. The Original Equipment Manufacturer (OEM) sector plays a pivotal role in enhancing the fly ash industry, providing advanced technologies and solutions that ensure efficient processing and utilization of this industrial byproduct.

Fly ash is recognized for its pozzolanic properties, which enable it to react chemically with lime in the presence of moisture, thereby contributing to the strength and durability of concrete. As a result, many construction companies are increasingly incorporating fly ash into their projects to achieve higher performance standards while simultaneously reducing their carbon footprint. This trend aligns with the global push for sustainable development and the need to minimize waste generation.

The Role of OEM in the Fly Ash Industry Exploring Opportunities for Sustainable Development

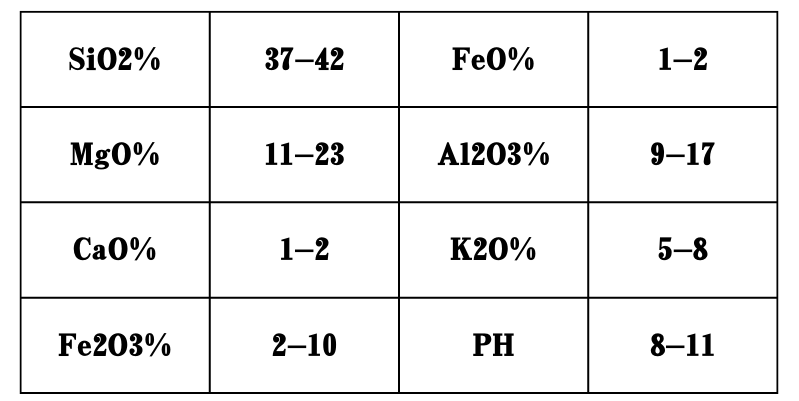

One of the key challenges in the fly ash industry is the variability in the quality and composition of fly ash from different sources. OEMs are addressing this challenge by developing sophisticated testing and quality control systems that can evaluate the properties of fly ash in real time. This capability allows manufacturers to make informed decisions regarding the blending of fly ash with other materials, ensuring that the final concrete mix meets the required specifications and performance standards.

oem loi fly ash factory

Moreover, OEMs are also playing a critical role in promoting the benefits of fly ash utilization. Through collaborations with industry stakeholders, they are educating contractors, architects, and engineers about the advantages of incorporating fly ash into their designs. This includes highlighting its benefits such as enhanced concrete performance, reduced water consumption, and diminished greenhouse gas emissions. By raising awareness and providing training, OEMs are helping to create a more sustainable future for the construction industry.

In addition to promoting fly ash utilization, OEMs are also focused on developing innovative recycling methods that not only preserve the environment but also create economic opportunities. By converting fly ash into valuable products such as lightweight aggregates or high-performance concrete, OEMs are helping to close the loop on waste materials. This circular economy approach not only minimizes landfill waste but also reduces the demand for virgin materials, fostering a sustainable ecosystem within the construction sector.

As the demand for sustainable building materials continues to rise, the role of OEMs in the fly ash industry will become increasingly significant. By investing in research and development, OEMs can foster advancements in fly ash processing technology and develop new applications for this versatile material. This not only benefits the environment but also provides economic incentives for power plants and manufacturers alike.

In conclusion, the relationship between OEMs and the fly ash industry is crucial for driving innovation and promoting sustainable practices. By harnessing advanced technology, improving quality control, and advocating for the use of fly ash, OEMs are positioning themselves as leaders in the transition toward green construction materials. As the industry evolves, collaboration between OEMs, manufacturers, and regulators will be essential to unlocking the full potential of fly ash, transforming it from a waste product into a cornerstone of sustainable building practices. Through these efforts, the fly ash industry can play a vital role in shaping a more sustainable future for construction and environmental stewardship.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025