oem iron oxide manufacturers

Understanding OEM Iron Oxide Manufacturers Quality, Applications, and Market Trends

In the manufacturing sphere, the demand for iron oxide pigments has been steadily rising due to their versatile applications across various industries. Original Equipment Manufacturer (OEM) iron oxide manufacturers play a crucial role in this sector, producing colored compounds essential for a diverse range of products, including paints, coatings, plastics, and construction materials.

What is Iron Oxide?

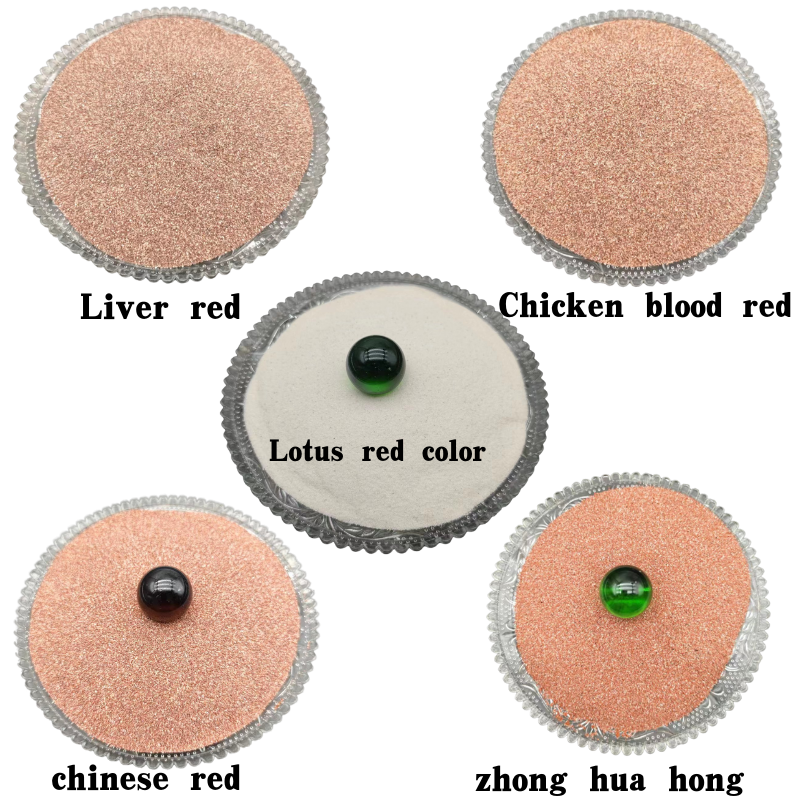

Iron oxide is a natural compound composed of iron and oxygen, presenting itself in various forms, such as red, yellow, and black pigments. These pigments are not only valued for their color but also for their stability, durability, and non-toxicity. Consequently, they are widely utilized in applications ranging from construction to cosmetics.

The Role of OEM Manufacturers

OEM iron oxide manufacturers specialize in the production of tailored pigment solutions for various clients, ranging from small businesses to large corporations. They often supply pigments that meet specific customer requirements, including color shades, particle sizes, and performance characteristics. By leveraging advanced processing techniques and technologies, OEM manufacturers can produce high-quality iron oxides that fulfill stringent industry standards.

One of the significant advantages of working with OEM iron oxide manufacturers is their ability to customize products. Companies can collaborate with manufacturers to develop unique formulations that cater to niche markets or specific applications. This flexibility allows businesses to differentiate their products, gaining a competitive edge in the market.

Quality Standards and Compliance

Ensuring product quality is paramount in the iron oxide manufacturing industry. Many OEM manufacturers adhere to international quality standards, including ISO certifications, which guarantee that their products meet safety and quality benchmarks. The use of rigorous testing methods, such as particle size distribution analysis and thermal stability tests, helps ensure that the iron oxide pigments produced are consistent and reliable.

oem iron oxide manufacturers

Moreover, compliance with environmental regulations is increasingly important. Leading OEM manufacturers often implement sustainable practices, focusing on minimizing waste and reducing carbon footprints. This commitment to sustainability not only aligns with global initiatives but also addresses the growing consumer demand for environmentally friendly products.

Diverse Applications

The versatility of iron oxide pigments is evident in their wide range of applications. In the construction industry, they are used to enhance the aesthetic appeal of concrete, tiles, and bricks. The pigments provide UV stability and resistance to fading, ensuring that structures retain their color over time.

In the coatings industry, iron oxides are employed in industrial coatings, automotive paints, and architectural applications. Their excellent weather resistance and opacity characteristics make them ideal for exterior surfaces exposed to varying environmental conditions.

Additionally, iron oxides find their way into the cosmetics industry, where they are used as colorants in products like foundations, eye shadows, and blushes. Their non-toxic nature and skin-friendly properties make them a preferred choice for formulators seeking safe and effective color solutions.

Market Trends and Future Outlook

The global market for iron oxide pigments is witnessing steady growth, driven by increasing demand from emerging economies and a shift towards environmentally friendly products. Innovation in manufacturing processes and the development of synthetic iron oxides are opening up new avenues for applications.

Furthermore, as industries focus on sustainability, the trend toward bio-based and eco-friendly pigments is likely to influence the production strategies of OEM iron oxide manufacturers. Companies that invest in research and development to create sustainable solutions will be well-positioned to capture market share in the future.

In conclusion, OEM iron oxide manufacturers are integral to supplying high-quality pigments necessary for a multitude of industrial applications. Their ability to adapt to market trends, focus on sustainability, and ensure product quality will determine their success in an evolving landscape. As demand for iron oxide continues to grow, manufacturers who prioritize innovation and compliance will thrive in this competitive industry.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025