OEM Glass Beads for Road Paint Manufacturing Solutions and Innovations

The Importance of OEM Glass Beads in Road Paint Production

In the contemporary world, road safety and visibility have become paramount concerns for urban planning and infrastructure development. One of the crucial materials that contribute significantly to road safety is glass beads, particularly those produced through Original Equipment Manufacturer (OEM) processes for road paint applications. This article delves into the significance and utility of OEM glass beads in enhancing road paint functionality and durability.

What are OEM Glass Beads?

OEM glass beads are small, spherical particles made from high-quality glass materials. They are manufactured under strict quality control standards to ensure uniform size, shape, and optical properties. These beads are typically incorporated into road marking paints to enhance retro-reflection, which is pivotal for improving night-time visibility on roads. When vehicle headlights strike these beads, they reflect light back towards the driver, significantly enhancing safety during nighttime and adverse weather conditions.

Benefits of Using OEM Glass Beads in Road Paint

1. Enhanced Visibility The primary function of glass beads in road paint is to improve visibility. By reflecting light effectively, they play a crucial role in ensuring that road markings remain visible even in low light conditions. This is particularly important for lane markings, pedestrian crossings, and other critical roadway indicators.

2. Durability OEM glass beads are designed to withstand harsh environmental conditions, including UV rays, moisture, and abrasion. Their durability ensures that road markings retain their reflective properties for longer periods, reducing the need for frequent repainting. This longevity leads to cost savings for municipalities and transit authorities.

oem glass beads road paint factory

3. Improved Aesthetics Aside from safety, the integration of glass beads in road paint can enhance the overall look of road markings. The reflective quality adds a shiny finish that can improve the visual appeal of the roadway, making it more inviting and well-maintained.

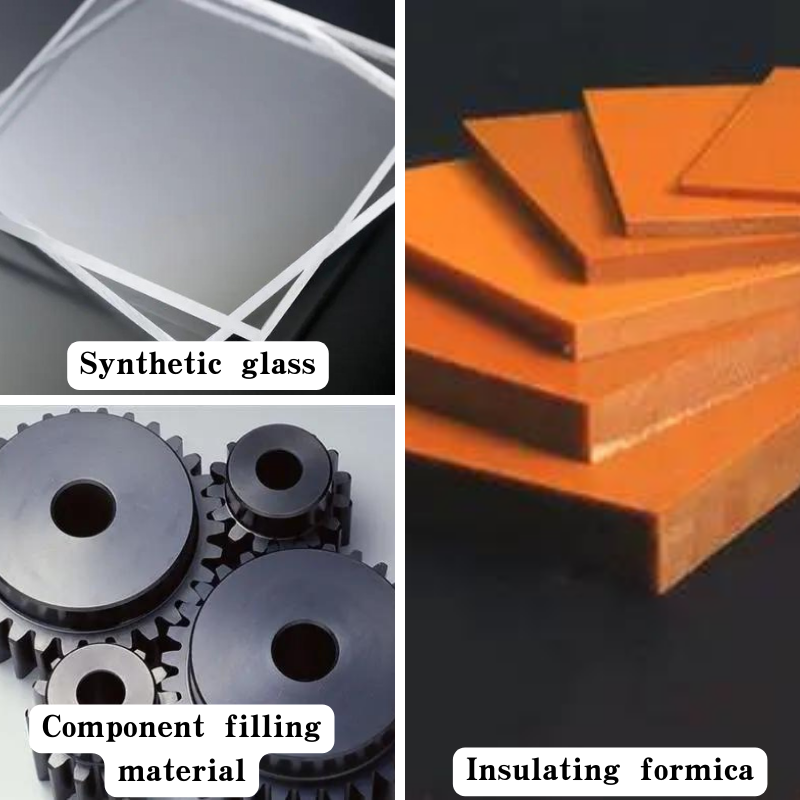

4. Versatile Applications OEM glass beads are not limited to just road markings. They can be used in various applications, including sports courts, airport runways, and even parking lots. Their versatile nature makes them a preferred choice for many infrastructure projects.

5. Environmental Considerations Many OEM glass bead manufacturers are increasingly adopting eco-friendly practices, producing beads from recycled glass sources. This not only helps in reducing waste but also supports sustainability efforts within the construction and infrastructure sectors.

The Manufacturing Process

The production of OEM glass beads involves several stringent processes that ensure their quality and performance. High-quality glass is melted and formed into beads, followed by a cooling process that solidifies their structure. The beads are then screened to achieve uniformity in size. Advanced technological methods such as precision grinding and polishing may be employed to enhance the reflective properties of the glass beads. Finally, rigorous testing is conducted to ensure that they meet industry standards before being supplied to road paint manufacturers.

Conclusion

The integration of OEM glass beads into road paints is a game-changer in the field of road safety and infrastructure development. Their ability to enhance visibility, ensure durability, and improve aesthetics not only contributes to safer roads but also promotes a more efficient use of resources in urban planning. As cities continue to evolve and expand, the reliance on innovative materials like OEM glass beads will undoubtedly become more significant. By investing in high-quality road marking solutions, we can pave the way for safer and more aesthetically pleasing environments for all road users. The future of road construction and maintenance rests on such advancements, making OEM glass beads an essential component of modern infrastructure projects.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025