OEM Manufacturer of Glass Beads for Blasting Applications and Solutions

Exploring the World of OEM Glass Beads Blasting Manufacturers

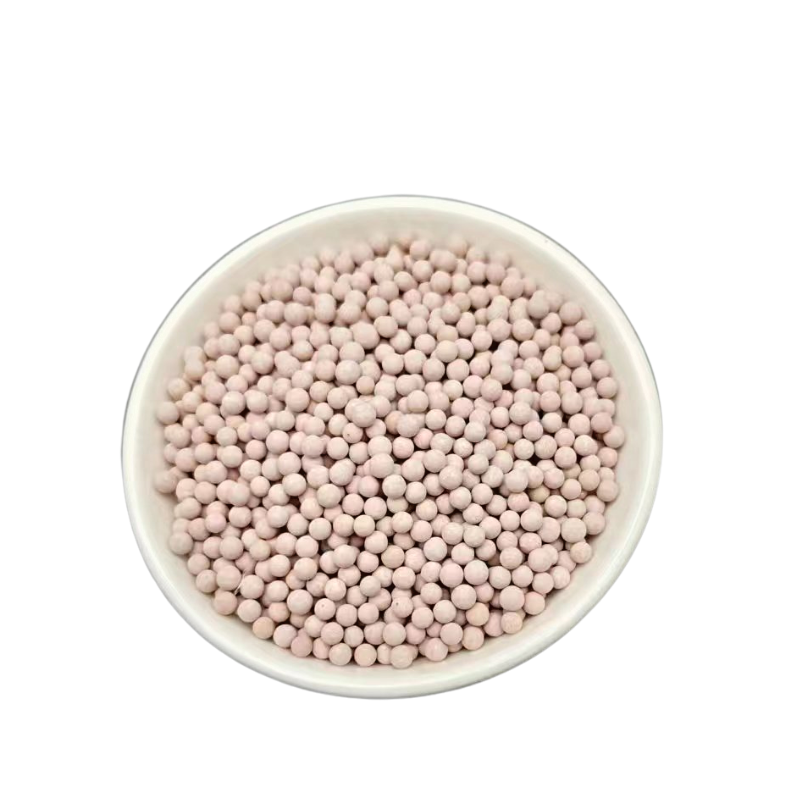

In the realm of surface preparation and finishing processes, glass bead blasting has become a popular method for achieving a smooth, matte finish on various materials. This technique involves the use of glass beads — small, spherical particles created from recycled glass — to clean, deburr, or finish the surfaces of metals, plastics, wood, and composites. With an increasing demand for efficient and effective surface treatment solutions, the role of OEM (Original Equipment Manufacturer) glass beads blasting manufacturers becomes crucial.

Understanding Glass Bead Blasting

Glass bead blasting is a form of abrasive blasting where the glass beads act as the abrasive medium. When propelled at high speeds against a surface, these beads impact the surface, removing contaminants, burrs, and imperfections. Unlike other abrasives, glass beads are non-toxic, environmentally friendly, and can be recycled, making them an attractive option for businesses looking to maintain high sustainability standards.

The process results in a clean, uniform surface that enhances the appearance of the material, prepares it for further coatings or finishes, and increases its longevity. Industries ranging from automotive to aerospace rely on this technique for surface treatment, making OEM glass beads blasting manufacturers a vital part of the supply chain.

The Role of OEM Manufacturers

OEM manufacturers specializing in glass beads blasting play a significant role in the production and distribution of these essential abrasives. They are responsible for producing high-quality glass beads tailored to the specific needs of various industries. By collaborating with businesses, these manufacturers can develop customized glass bead solutions that meet precise specifications.

One of the key advantages of working with OEM manufacturers is the ability to ensure consistent quality and size of the glass beads. The performance of glass bead blasting is highly dependent on the size and hardness of the beads used. OEM manufacturers utilize advanced technologies and stringent quality control measures to guarantee that their products meet industry standards and customer requirements.

oem glass beads blasting manufacturer

Innovations in Glass Bead Production

As industries evolve and seek more efficient and effective solutions, OEM glass beads blasting manufacturers are also innovating in their production processes. Many companies incorporate advanced techniques, such as automated production lines and precision sizing equipment, to ensure uniform bead production. This innovation not only increases the efficiency of manufacturing but also reduces production costs, allowing manufacturers to offer competitive pricing to their clients.

Additionally, some manufacturers are exploring sustainable practices in their production processes. The use of recycled glass in the creation of glass beads is a notable trend, aligning with global efforts to reduce waste and promote sustainability. By recycling glass, OEM manufacturers can contribute to environmental conservation while providing high-quality products for blasting applications.

Choosing the Right OEM Manufacturer

When selecting an OEM glass beads blasting manufacturer, businesses should consider several factors. The manufacturer’s reputation, experience in the industry, and commitment to quality are essential aspects to evaluate. It’s also important to assess their ability to provide customized solutions and technical support throughout the process.

Customer testimonials and case studies can offer valuable insights into the manufacturer's reliability and product performance. Additionally, exploring their commitment to sustainability and environmental practices can help businesses align their values with those of their suppliers.

Conclusion

In conclusion, OEM glass beads blasting manufacturers are key players in the surface preparation industry. Their ability to provide quality glass beads tailored to specific applications not only enhances the performance of blasting processes but also contributes to sustainable manufacturing practices. As businesses continue to prioritize efficiency and environmental responsibility, the demand for high-quality OEM solutions in glass bead blasting will only grow. By understanding the importance of this industry and choosing the right manufacturer, companies can elevate their finishing processes and achieve superior results.

Share

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025

-

High-Quality Iron Oxide Pigment for Vibrant Colors & DurabilityNewsJul.28,2025