OEM Glass Beads Blasting Manufacturers for High-Quality Surface Finishing Solutions

The Role of OEM Glass Beads Blasting in Modern Manufacturing

In the ever-evolving world of manufacturing, surface treatment plays a crucial role in the enhancement of product quality and longevity. One of the most effective methods of achieving superior surface finishes is through the use of glass beads blasting. For industries seeking customized solutions, Original Equipment Manufacturer (OEM) glass beads blasting factories have become pivotal in providing tailored services that meet specific manufacturing requirements.

Understanding Glass Beads Blasting

Glass beads blasting is a process that involves the use of finely manufactured glass beads as an abrasive medium to clean, strengthen, or polish the surface of various materials. This technique is particularly favored for its non-destructive nature, making it suitable for delicate and intricate components. The process involves propelling glass beads at high velocity towards the surface of the workpiece, thereby producing a uniform finish while minimizing the risk of altering the original dimensions or properties of the material.

The Benefits of OEM Glass Beads Blasting

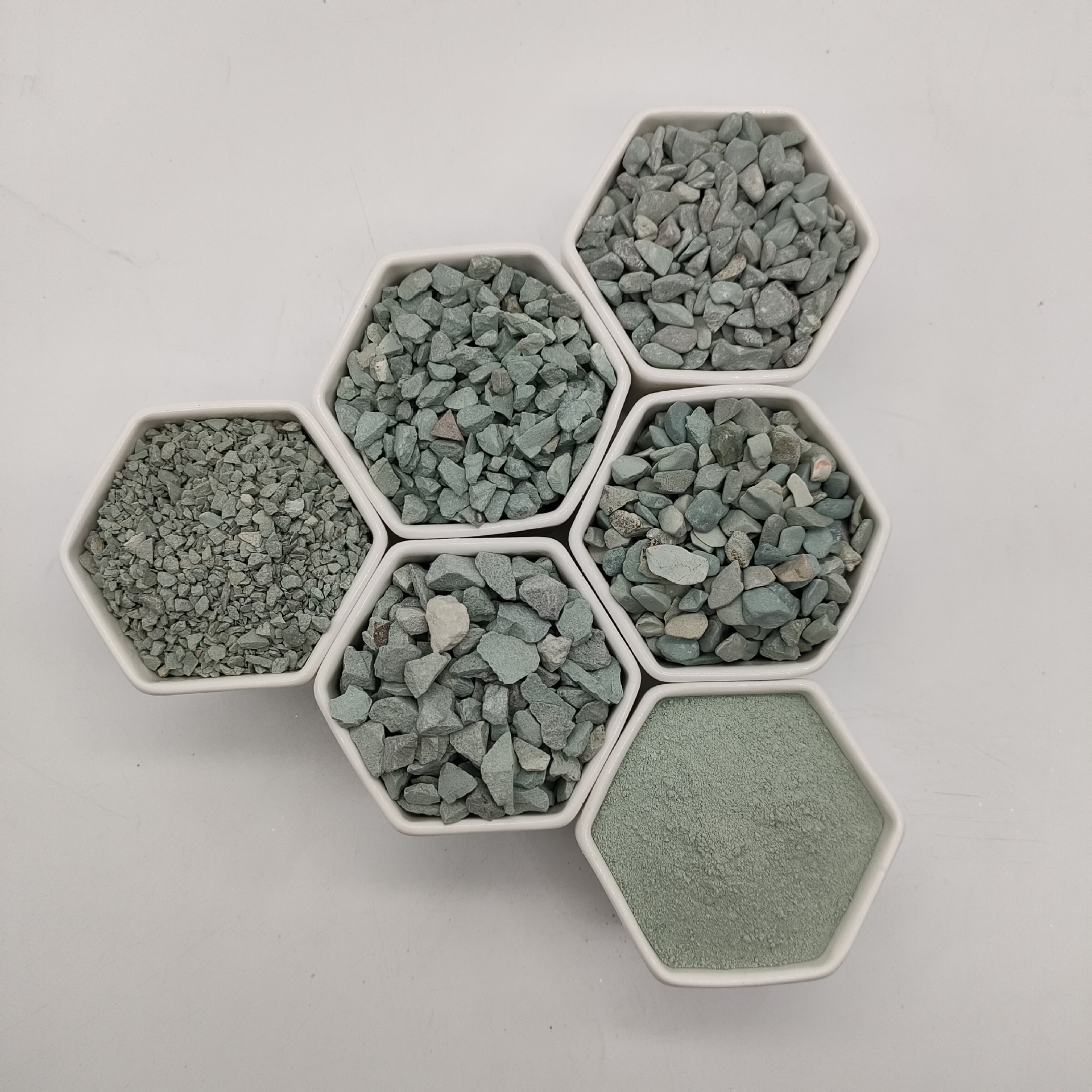

One of the primary advantages of utilizing OEM glass beads blasting factories is the customization they offer. These facilities are equipped to provide specific bead sizes, compositions, and blasting techniques tailored to the unique requirements of a client’s production needs. For instance, certain industries may require a finer finish for cosmetic products, while others may need a more aggressive blasting process for industrial components.

Moreover, OEM glass beads offer consistency and reliability. Factory standards ensure that the glass beads produced adhere to strict quality control measures, resulting in a uniform surface finish that meets industry standards. This consistency is crucial for manufacturers, as it directly impacts the quality of the final product.

Applications Across Industries

The versatility of glass beads blasting makes it applicable across various sectors. In the automotive industry, for instance, glass beads are used to clean components such as engine blocks and chassis parts, ensuring they are free from contaminants and prepared for further treatment. In the aerospace industry, precision and weight are critical factors; hence glass beads are used to develop lighter components without compromising strength.

oem glass beads blasting factories

Electronics manufacturers also benefit significantly from glass beads blasting, where the process aids in cleaning circuit boards and other delicate components, ensuring optimal functionality

. Furthermore, the medical field utilizes this technique for sterilizing surgical instruments, maintaining high standards of hygiene and safety.Environmental Considerations

In an age where sustainability is paramount, the use of glass beads in blasting processes also aligns with environmental considerations. Unlike traditional sandblasting, which can produce harmful silica dust, glass beads generate far less airborne particulate matter. They are also reusable, which reduces waste and minimizes the environmental footprint of manufacturing processes.

Furthermore, OEM factories are increasingly adopting eco-friendly practices by utilizing advanced technologies that enhance the efficiency of the glass beads blasting process. These innovations not only improve performance but also contribute to energy savings and reduced material consumption.

The Future of Glass Beads Blasting

As industries continue to evolve and the demand for high-quality finishes grows, the role of OEM glass beads blasting factories is set to expand. Technological advancements such as automated blasting systems and improved glass bead formulations will usher in new possibilities for surface treatment. Additionally, the integration of Industry 4.0 practices, including data analytics and smart manufacturing, will enhance operational efficiency, enabling factories to provide even better customized solutions.

Conclusion

In conclusion, OEM glass beads blasting factories represent a critical component in modern manufacturing. Their ability to provide customized, high-quality surface treatments positions them as invaluable partners for industries seeking to enhance their product quality and operational efficiency. As the demand for precision and sustainability continues to rise, glass beads blasting is poised to remain at the forefront of surface treatment technologies, driving innovation and excellence across various sectors. By embracing these advancements, manufacturers can achieve superior finishes, contributing to the overall success and competitiveness of their products in a global marketplace.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025