oem glass ball manufacturer

The Rising Demand for OEM Glass Balls A Comprehensive Overview

In today's industrial landscape, the demand for specialized components such as glass balls has surged significantly. As manufacturers focus on achieving high quality, precision, and customization in their products, Original Equipment Manufacturer (OEM) glass ball suppliers have emerged as pivotal players in various sectors. This article delves into the significance of OEM glass ball manufacturing, its applications, and the factors driving its growth in the market.

What Are OEM Glass Balls?

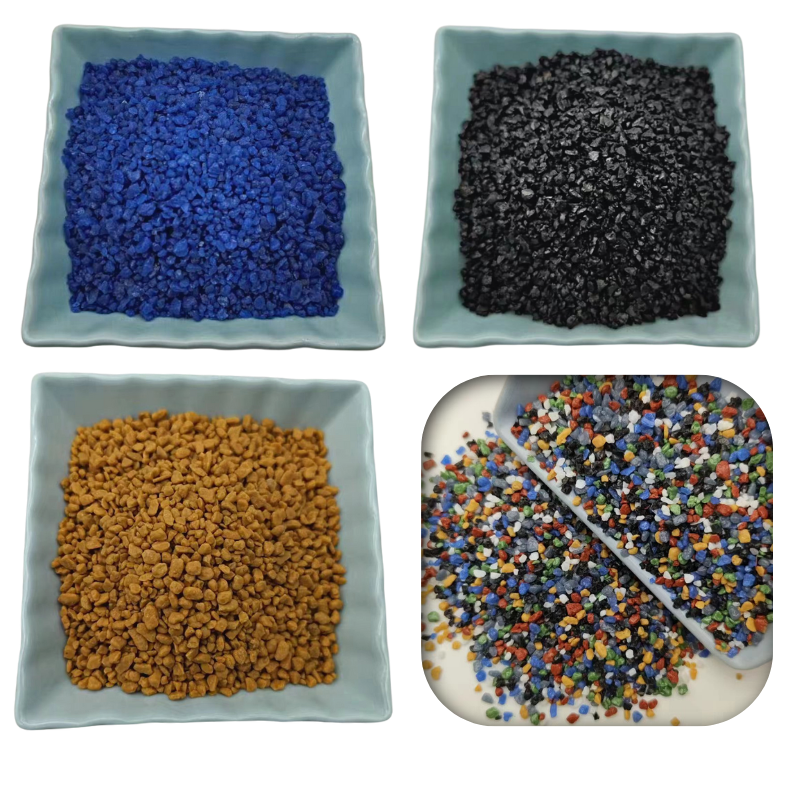

OEM glass balls are precision-engineered glass spheres specifically designed to meet the unique requirements of different industries. These balls can be produced in various sizes, colors, and finishes, making them suitable for an array of applications. The term OEM reflects the nature of these products being tailored for other companies that integrate them into their own products. Consequently, the manufacturing process involves stringent quality controls, advanced technology, and a commitment to customer specifications.

Applications of Glass Balls

The versatility of glass balls lends itself to numerous applications across diverse industries. Here are some key sectors where OEM glass balls are commonly used

1. Automotive Industry Glass balls are utilized in several automotive components, such as in fuel injectors and other precision-engineered parts. Their lightweight yet durable properties enhance performance and efficiency.

2. Aerospace In the aerospace sector, OEM glass balls are used in various fasteners and connectors. Their ability to withstand extreme conditions makes them ideal for applications in aircraft manufacturing.

3. Cosmetics and Personal Care Many cosmetic companies incorporate glass balls in their packaging to enhance aesthetics and functionality. These balls can facilitate smooth product dispensing and add a premium feel to the product.

4. Medical Equipment In the healthcare sector, glass balls are used in dosing devices, syringes, and various diagnostic equipment. Their chemical resistance and non-reactive nature make them suitable for medical applications.

oem glass ball manufacturer

5. Decorative Uses Beyond industrial applications, glass balls are also popular in home decor and craft projects. Their visual appeal adds elegance to vases, centerpieces, and garden decorations.

Factors Driving Growth

Several factors contribute to the increasing demand for OEM glass balls in the market

1. Customization Requirements Industries are leaning towards customized solutions to differentiate their products. OEM manufacturers provide options for customization, meeting unique specifications that cater to the individual needs of clients.

2. Technological Advancements With advancements in manufacturing technology, producing high-quality glass balls has become more efficient and cost-effective. Innovations such as automated production lines and improved quality control systems enhance the reliability of glass ball suppliers.

3. Sustainability Initiatives The push for sustainable practices across industries has led to a preference for glass over plastic. Glass is recyclable, non-toxic, and has a lower environmental impact compared to some synthetic materials, making it an attractive choice for companies focused on sustainability.

4. Global Market Expansion The growth of emerging markets and increased globalization have created new opportunities for OEM glass ball manufacturers. As industries expand their footprints internationally, the demand for customized components—like glass balls—continues to rise.

Conclusion

As the landscape of manufacturing continues to evolve, the importance of high-quality OEM glass balls cannot be overstated. Their diverse applications, coupled with the growing demand for customization and sustainability, position them as essential components across various sectors. For manufacturers looking to stay competitive, partnering with reliable OEM glass ball suppliers can provide the necessary edge to innovate and meet the dynamic needs of the market. With ongoing technological advancements and an emphasis on quality, the future of OEM glass ball manufacturing appears bright, promising sustained growth and innovation in the years to come.

Share

-

Premium Ceramsite for Plants & Hydroponics - Ideal Growing MediaNewsAug.10,2025

-

Premium Mineral Sepiolite Powder: Versatile Adsorbent & FillerNewsAug.09,2025

-

Premium Talcum Powder - Smoothness & Purity GuaranteedNewsAug.08,2025

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025