oem fly ash in concrete blocks factories

The Role of OEM Fly Ash in Concrete Block Manufacturing

The construction industry has made significant strides towards sustainability, and one of the materials at the forefront of this movement is fly ash. As an industrial byproduct of coal combustion, fly ash is increasingly used in concrete block manufacturing due to its numerous benefits. Original Equipment Manufacturers (OEMs) are at the helm of these advancements, introducing innovative methods to enhance the efficiency and performance of concrete blocks through the incorporation of fly ash.

Understanding Fly Ash and Its Benefits

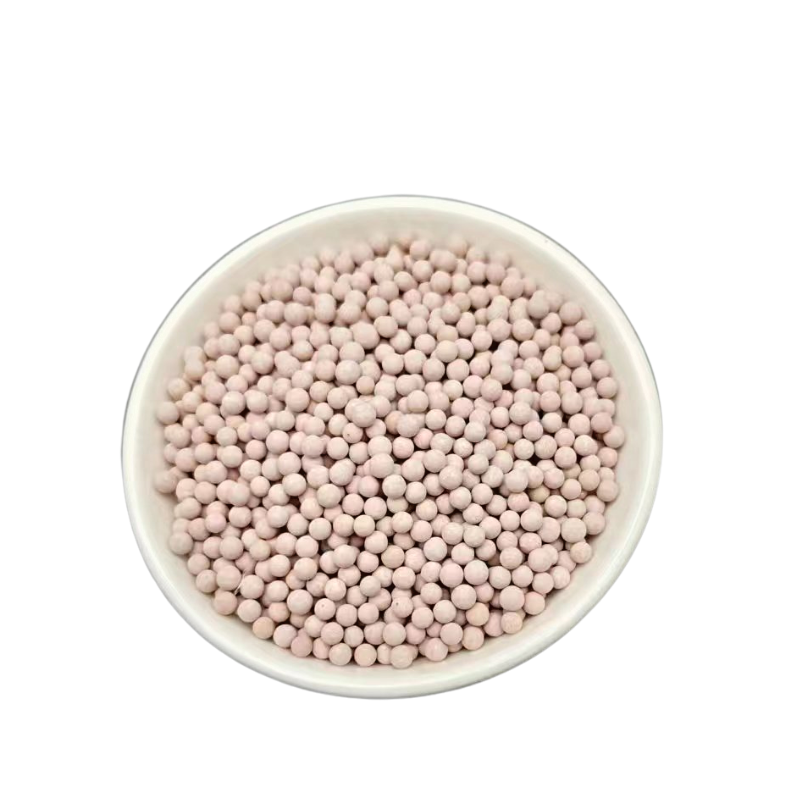

Fly ash is a fine powder that is obtained from the flue gases of coal-fired power plants. It is a pozzolanic material, meaning it can react with calcium hydroxide in the presence of water to form additional cementitious compounds. This key property makes fly ash an excellent additive for concrete, providing multiple advantages

1. Enhanced Durability Concrete blocks made with fly ash are known for their improved durability compared to those made with traditional Portland cement alone. The presence of fly ash helps reduce the permeability of the concrete, which in turn enhances resistance to environmental factors, such as water intrusion and chemical attacks.

2. Reduced Carbon Footprint Using fly ash in concrete block production significantly lowers the carbon footprint of the resulting blocks. The production of Portland cement is a major source of carbon dioxide emissions, accounting for approximately 5-7% of global emissions. By replacing a portion of the cement with fly ash, manufacturers can contribute to reduced greenhouse gas emissions.

3. Cost-Effectiveness Fly ash is often less expensive than traditional cement materials, which can lead to substantial cost savings for manufacturers. By utilizing fly ash as a partial replacement for cement, OEMs can produce high-quality concrete blocks at a lower cost, making them more competitive in the market.

4. Workability and Performance The spherical shape of fly ash particles contributes to improved workability and flow of concrete mixtures. This leads to easier mixing and placement during the manufacturing process, enhancing overall productivity. Moreover, concrete blocks produced with fly ash often exhibit superior mechanical properties, such as increased compressive strength and reduced shrinkage.

The Role of OEMs in Fly Ash Utilization

oem fly ash in concrete blocks factories

Original Equipment Manufacturers are critical players in harnessing the potential of fly ash for concrete block production

. They are responsible for designing and manufacturing the machinery and technology needed to efficiently integrate fly ash into the production process.1. Innovative Machinery Design OEMs are continually developing advanced machinery equipped with precise mixing capabilities to ensure optimal distribution of fly ash within concrete mixtures. This technology helps achieve consistent quality in the final product, meeting the rigorous standards of the construction industry.

2. Quality Control and Testing To ensure the performance and durability of fly ash concrete blocks, OEMs implement stringent quality control measures. This includes regular testing of the fly ash itself as well as the final concrete products. By adhering to standards set by organizations such as ASTM and AASHTO, OEMs can guarantee that their products perform as expected in real-world applications.

3. Research and Development OEMs are heavily invested in research and development initiatives aimed at exploring new uses for fly ash and improving the production process. Collaborations with academic institutions and industry leaders can lead to innovative applications for fly ash, further enhancing the sustainability of concrete block production.

Challenges and Future Prospects

While the use of fly ash in concrete block manufacturing presents numerous advantages, challenges remain. The availability of high-quality fly ash can vary depending on local power plants, and fluctuations in coal use can impact supply. Additionally, public perception of using industrial byproducts in construction can pose a barrier to widespread adoption.

However, with increasing regulatory support for sustainable building materials and growing awareness of environmental issues, the future for fly ash in concrete block manufacturing appears promising. OEMs are well-positioned to lead this transformation, leveraging technology and innovation to create more sustainable building materials that meet the demands of the 21st century.

Conclusion

In conclusion, OEM fly ash is reshaping the landscape of concrete block manufacturing by providing a sustainable, cost-effective, and high-performance alternative to traditional materials. As the construction industry continues to evolve, the integration of fly ash will play a crucial role in promoting environmental stewardship, enhancing durability, and improving the economic viability of building projects. The ongoing collaboration between OEMs and other stakeholders will further drive the adoption of fly ash and propel the industry towards a more sustainable future.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025