oem fly ash in cement factories

The Role of OEM Fly Ash in Cement Factories A Sustainable Approach to Construction

Fly ash, a byproduct of coal combustion in power plants, has emerged as a significant material in the construction industry, particularly in the production of cement. Over the years, Original Equipment Manufacturers (OEMs) have recognized the potential of incorporating fly ash into cement production processes, leading to numerous advantages. This article explores the implications of using OEM fly ash in cement factories, emphasizing its sustainability, cost-effectiveness, and performance benefits.

Understanding Fly Ash

Fly ash is a fine powder that is collected from the flue gases of coal-fired power plants. It primarily consists of silica, alumina, and iron oxide, and its properties vary depending on the source of the coal burned. Traditionally, fly ash has been viewed as a waste product, posing disposal challenges for power plants. However, its pozzolanic properties—ability to react with calcium hydroxide in the presence of water to form compounds that have cement-like properties—have made it a valuable additive in cement and concrete production.

Benefits of Using OEM Fly Ash in Cement Manufacturing

1. Environmental Sustainability The use of fly ash in cement production significantly reduces the environmental impact of both coal-fired power generation and cement manufacturing. By repurposing this industrial byproduct, cement factories can diminish the need for lime and other raw materials, resulting in lower carbon emissions. This aligns with the global push for sustainable construction practices and helps reduce landfill waste associated with fly ash disposal.

2. Cost-Effectiveness Incorporating fly ash into cement production offers a cost-effective alternative to traditional materials. Fly ash can often be sourced at a lower price than virgin materials, thus reducing overall production costs for cement manufacturers. Additionally, the use of OEM fly ash can lead to reduced energy consumption during the cement manufacturing process.

oem fly ash in cement factories

3. Enhanced Performance Cement blended with fly ash often exhibits improved mechanical properties. It can enhance the workability of concrete, reduce shrinkage, and improve durability. The pozzolanic reaction contributes to the strength of the concrete over time, allowing for longer-lasting structures. As a result, projects that utilize fly ash can benefit from increased longevity, reduced maintenance costs, and improved performance in various environmental conditions.

4. Regulatory Compliance and Market Demand With increasing regulations aimed at reducing carbon footprints and promoting sustainable practices, cement manufacturers that incorporate fly ash can better comply with environmental standards. Furthermore, market demand is shifting towards more eco-friendly construction materials. Companies that utilize OEM fly ash can enhance their competitive advantage and appeal to environmentally conscious consumers.

Challenges and Considerations

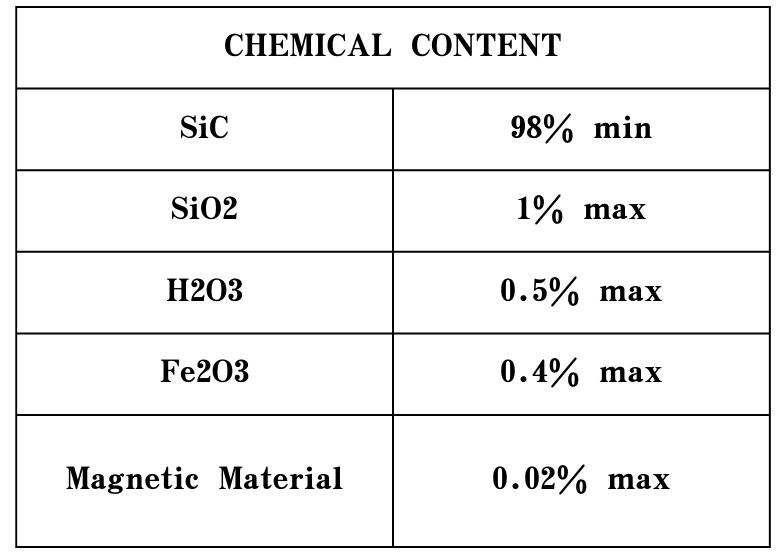

Despite the numerous advantages, the use of fly ash in cement production is not without challenges. The variability in the chemical composition and performance characteristics of fly ash can affect the consistency of cement products. Cement manufacturers must invest in proper quality control measures to ensure that the fly ash used meets the necessary specifications.

Additionally, the declining use of coal for power generation in some regions has also led to a reduction in fly ash availability, prompting the need for alternative sources or supplementary materials. Developing strategies to source high-quality fly ash and assessing its long-term performance in various applications will be essential for the sustainability of this approach.

Conclusion

The integration of OEM fly ash into cement factories represents a significant step toward a more sustainable construction industry. By leveraging the environmental, economic, and performance benefits of fly ash, cement manufacturers can play a pivotal role in reducing carbon emissions and promoting circular economy principles. As the construction sector moves forward, embracing innovative solutions like OEM fly ash will be crucial for meeting both building needs and environmental responsibilities.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025