OEM Dolomite Powder for Paint Production and Its Benefits for Manufacturers

The Importance of OEM Dolomite Powder in Paint Manufacturing

In the realm of industrial manufacturing, particularly in paint formulation, the choice of raw materials plays a crucial role in determining the quality and performance of the final product. One such material that has gained significant attention in recent years is OEM dolomite powder. This naturally occurring mineral, primarily composed of calcium magnesium carbonate, offers a range of benefits that make it an ideal choice for paint manufacturers.

What is Dolomite Powder?

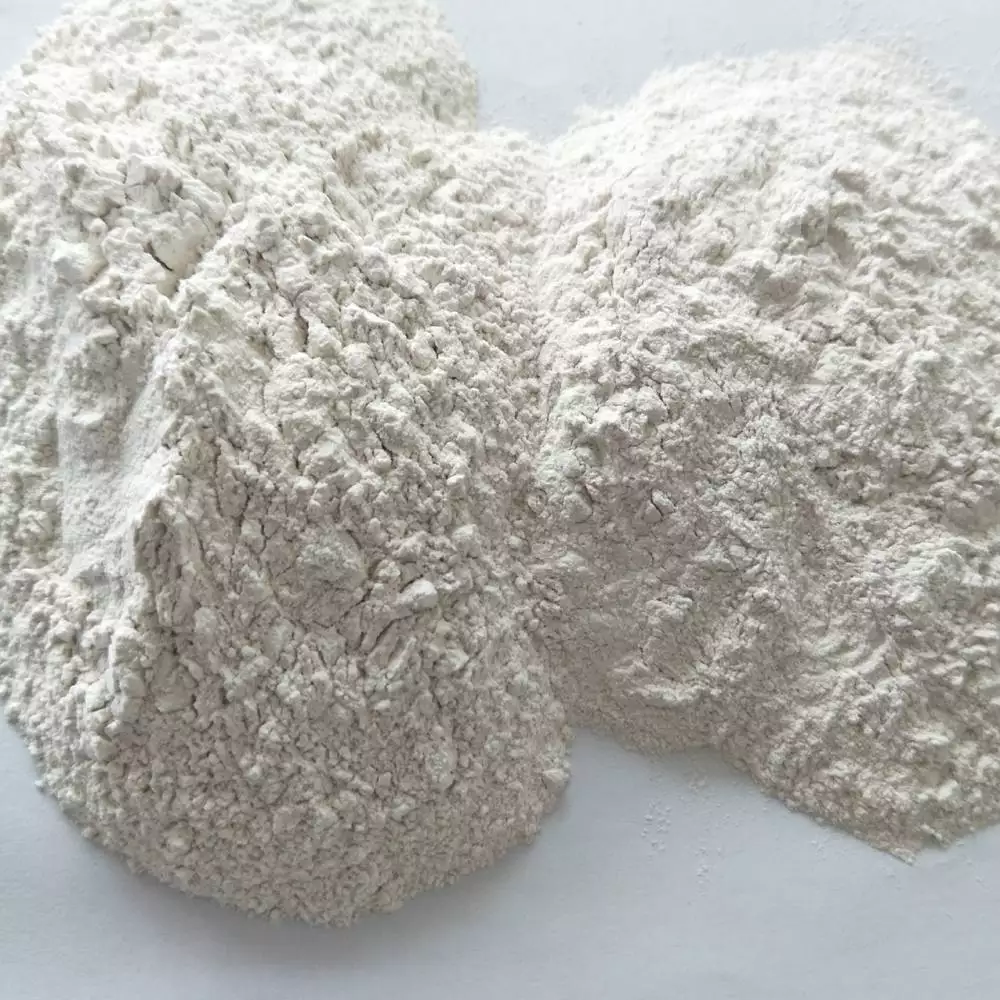

Dolomite powder is created by finely grinding the dolomite mineral, which is primarily found in sedimentary rocks. This powder can vary in particle size and is often categorized based on its brightness, particle size distribution, and chemical composition. Its unique properties, such as high whiteness, low oil absorption, and excellent chemical stability, make it suitable for a variety of applications, especially in the paint industry.

Advantages of Using OEM Dolomite Powder in Paints

1. Enhanced Opacity and Whiteness One of the key advantages of using OEM dolomite powder in paint formulations is its ability to enhance the opacity and whiteness of the paint. The mineral's bright white color helps in achieving a uniform and vibrant finish, allowing manufacturers to produce paints that cover surfaces effectively with fewer coats, thus saving time and resources.

2. Improved Scratch and Abrasion Resistance Dolomite powder contributes to the mechanical strength of paints, providing improved resistance to scratching and abrasion. This is particularly important for exterior paints that are exposed to various weather conditions and physical wear and tear. By incorporating dolomite powder, manufacturers can enhance the durability of their products, extending the life of painted surfaces.

oem dolomite powder for paint manufacturer

3. Cost-Effectiveness Sourcing OEM dolomite powder can significantly reduce production costs for paint manufacturers. Due to its nature as an abundant mineral, dolomite powder is often more affordable compared to other fillers and additives. This cost-effectiveness allows manufacturers to maintain competitive pricing while ensuring high-quality paint production.

4. Improved Application Properties The fine particle size of dolomite powder facilitates better dispersion in the paint medium, leading to improved application properties. Paints containing dolomite exhibit excellent flow and leveling characteristics, making them easier to apply and resulting in a smoother finish. This is particularly beneficial for both professional painters and DIY enthusiasts.

5. Non-Toxic and Environmentally Friendly With growing concerns about environmental sustainability and toxicity in manufacturing processes, dolomite powder stands out as a non-toxic alternative. Its natural composition poses minimal risk to human health and the environment, making it an attractive choice for environmentally conscious paint manufacturers.

6. Versatility in Formulations Dolomite powder is highly versatile and can be used in various types of paint formulations, including water-based, solvent-based, and even specialty paints. Its adaptability allows manufacturers to cater to a wide range of customer needs, from residential to industrial applications.

Conclusion

In conclusion, OEM dolomite powder is a valuable ingredient in the paint manufacturing industry, offering numerous advantages that enhance the quality, durability, and cost-effectiveness of paints. Its properties make it an excellent choice for manufacturers looking to create high-performance coatings that meet market demands while adhering to regulatory standards for safety and environmental impact. As the industry continues to evolve, the utilization of OEM dolomite powder is likely to increase, maintaining its status as a staple in paint formulations and contributing to innovation in the field. By investing in high-quality dolomite powder, paint manufacturers can not only improve their products but also position themselves competitively in the market.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025