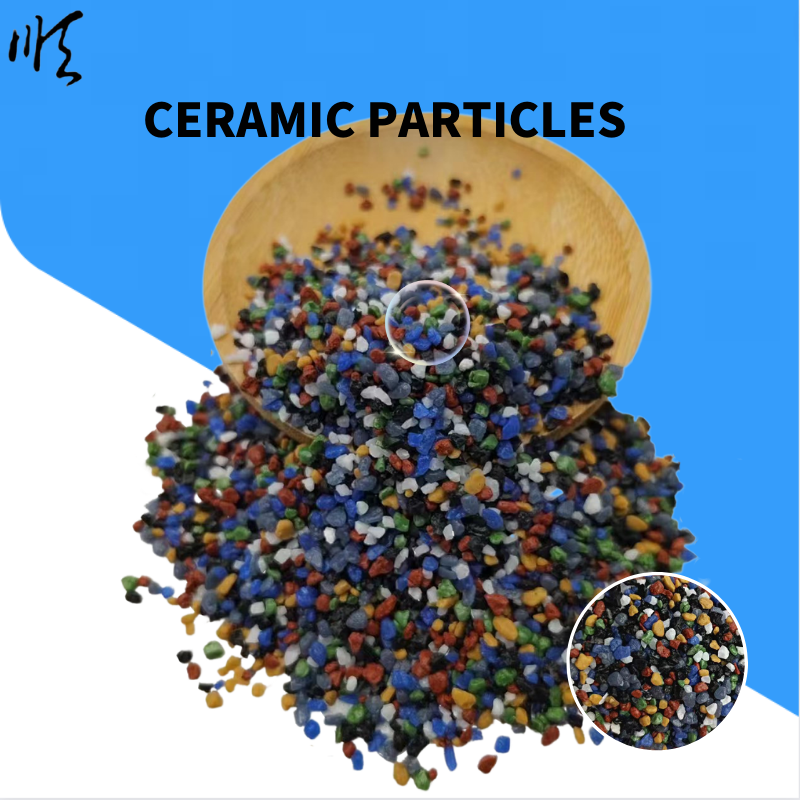

oem colour stone manufacturers

The Rise of OEM Colour Stone Manufacturers A Comprehensive Overview

In the realm of stone manufacturing, Original Equipment Manufacturer (OEM) colour stone producers have carved a significant niche, catering to the diverse demands of the construction and design industries. This article delves into the evolution of OEM colour stone manufacturers, their role in the market, the advantages they offer, and the trends shaping their future.

Understanding OEM Colour Stones

OEM colour stones are produced by manufacturers who partner with various brands to create bespoke products featuring specific colours and finishes. These stones are typically used in various applications such as flooring, countertops, wall cladding, and decorative pieces. With the growing consumer demand for unique and aesthetically pleasing materials, OEM manufacturers have emerged as crucial players in the stone industry.

The Evolution of the Market

Historically, stone production was relatively standard, focusing primarily on natural hues and traditional finishes. However, the late 20th century heralded a shift towards customization. As interior design became increasingly important, architects and designers sought ways to integrate personal branding into their projects. OEM colour stone manufacturers responded by adopting advanced technologies and production techniques, enabling them to offer a wide variety of shades, textures, and finishes.

The Advantages of OEM Colour Stones

1. Customization One of the primary advantages of working with OEM colour stone manufacturers is the ability to create customized products to meet specific project requirements. Whether it’s a unique shade to match a brand’s identity or a specific finish to achieve a desired texture, OEM manufacturers can accommodate various requests.

2. Quality Control OEM manufacturers often boast superior quality control processes. By maintaining a close relationship with their clients, they ensure that the final product meets the expected standards. Rigorous testing and quality checks throughout the production process guarantee that the stones are durable, resilient, and aesthetically pleasing.

3. Cost-Effectiveness Partnering with OEM manufacturers can also lead to cost savings. By streamlining the production process and reducing the need for extensive inventory management, companies can optimize their operations and deliver products at competitive prices. Furthermore, the ability to source materials globally allows OEM manufacturers to offer a range of options that can suit various budgets.

oem colour stone manufacturers

4. Sustainability As environmental concerns take precedence in many industries, OEM colour stone manufacturers are increasingly adopting sustainable practices. By focusing on eco-friendly materials and processes, they can offer products that not only appeal to consumers' aesthetic preferences but also align with their values regarding sustainability.

Trends Shaping the Future of OEM Colour Stone Manufacturers

As we move forward, several trends are emerging within the market that could redefine the landscape of OEM colour stone production.

1. Increased Digitalization The integration of advanced technologies such as 3D modeling, virtual reality, and artificial intelligence is transforming how OEM manufacturers operate. These technologies allow for more efficient design processes, enabling quicker adjustments based on client feedback and preferences.

2. Sustainable Practices With growing awareness of environmental issues, more OEM manufacturers are adopting sustainable sourcing and production methods. This shift not only contributes to their reputation as responsible producers but also meets the demands of environmentally conscious consumers.

3. Globalization The expansion of global trade has enabled OEM colour stone manufacturers to access a wider range of raw materials and innovative techniques from around the world. This trend is fostering more collaboration across borders, leading to unique products that blend different cultural influences.

4. Increased Consumer Empowerment Today’s consumers are more informed and have higher expectations regarding product personalization. This shift is prompting OEM manufacturers to prioritise client collaboration and feedback during the design and production phases, enabling a more customer-centric approach.

Conclusion

The landscape of OEM colour stone manufacturing is rapidly evolving, driven by innovation, sustainability, and the demand for customization. As these manufacturers continue to adapt to changing market dynamics and consumer preferences, they will play an increasingly vital role in property development, construction, and design. By embracing these trends and leveraging their strengths, OEM colour stone manufacturers are not only securing their place in the market but are also setting the pace for the future of the stone industry.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025