OEM Fine Calcium Carbonate Powder Manufacturer for Various Industries

The Significance of OEM Calcium Carbonate Powder (CaCO3) Factories

Calcium carbonate (CaCO3) is one of the most widely used industrial minerals, found in a variety of applications across sectors such as construction, plastics, rubber, agriculture, and food production. As the demand for high-quality calcium carbonate continues to grow, Original Equipment Manufacturer (OEM) factories have played a crucial role in supplying tailored products to meet specific market needs. This article delves into the importance of OEM calcium carbonate powder factories and their contributions to various industries.

Understanding Calcium Carbonate

Calcium carbonate exists in three main forms chalk, limestone, and marble. It is a naturally occurring substance that is refined for industrial use by crushing, grinding, and classifying. The resulting powder is utilized for its various properties, such as whiteness, low oil absorption, chemical inertness, and high purity. These characteristics make calcium carbonate ideal for a multitude of applications, from the production of paper and paint to serving as a filler in plastics.

The Role of OEM Factories

OEM factories specialize in providing customized manufacturing solutions for specific client needs. These factories produce calcium carbonate powder tailored to the specifications provided by their clients, ensuring that the end product meets the unique requirements for various applications. The increasing complexity of industrial applications necessitates high standards of quality and purity, which OEM factories are equipped to deliver.

One significant advantage of OEM manufacturers is their ability to fabricate products in different sizes and grades. This versatility enables them to cater to a broad range of industries. For example, in the paint industry, the demand for fine calcium carbonate that can produce a smooth finish is vastly different from the needs of the construction sector, which may require more coarse material for cement production. By leveraging their expertise and technology, OEM calcium carbonate factories can provide the right specifications for each application.

Quality Control and Certification

oem calcium carbonate powder caco3 factory

Quality control is paramount in the production of calcium carbonate. OEM factories invest heavily in stringent quality control processes to ensure that their products meet international standards. This includes regular testing for purity, particle size distribution, and other critical parameters. Many of these factories are certified to ISO standards, which reinforces their commitment to quality and safety.

Furthermore, they often utilize advanced processing techniques and state-of-the-art equipment, ensuring that their calcium carbonate is not only high grade but also consistent in quality. This is particularly essential in industries like pharmaceuticals and food production, where contaminants can pose serious health risks.

Environmental Considerations

In addition to maintaining high-quality standards, OEM calcium carbonate manufacturers are increasingly focusing on sustainable practices. The extraction and processing of calcium carbonate can have substantial environmental impacts, from landscape disruption to carbon emissions. Many factories are actively seeking more eco-friendly methods of production and are adopting practices such as recycling and utilizing waste products in their processes.

Furthermore, by producing calcium carbonate powder that can replace more harmful substances in various applications, OEM factories contribute to environmental sustainability. For instance, in the manufacturing of plastics, substituting calcium carbonate for more harmful fillers can reduce the overall environmental footprint of the resulting products.

Conclusion

The role of OEM calcium carbonate powder factories is crucial in accommodating the diverse requirements of various industries. With a focus on customization, quality control, and sustainability, these factories are well-positioned to meet the growing demands for high-quality calcium carbonate in an ever-evolving market. As industries continue to seek innovative solutions and materials that adhere to stringent quality and environmental standards, OEM manufacturers will remain at the forefront, driving both growth and sustainability in the mineral sourcing sector.

Investing in OEM calcium carbonate powder not only ensures access to high-quality products but also fosters a collaborative approach to meeting the needs of modern industries while considering environmental impacts. As we move towards a more sustainable future, the significance of these factories will undoubtedly continue to grow.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

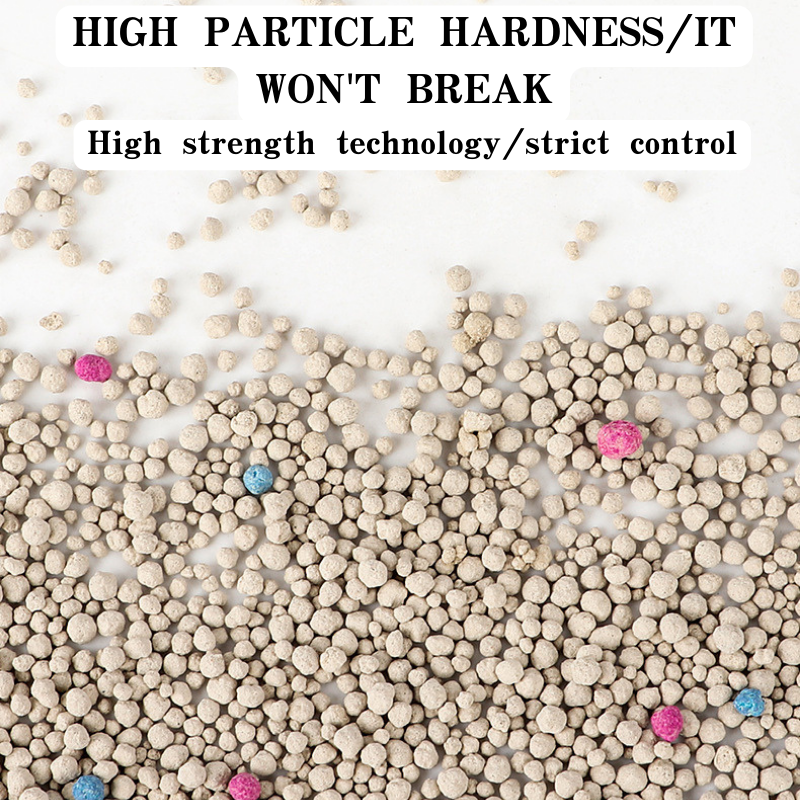

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025