oem bentonite clay powder factories

Exploring OEM Bentonite Clay Powder Factories A Comprehensive Overview

In the diverse world of industrial minerals, bentonite clay stands out for its unique properties and versatile applications. From the construction industry to cosmetics and pharmaceuticals, bentonite's uses are expansive. With a growing demand for high-quality bentonite products, the role of OEM (Original Equipment Manufacturer) factories has become increasingly important. This article delves into the intricacies of OEM bentonite clay powder factories, their processes, benefits, and significance in modern industries.

What is Bentonite Clay?

Bentonite is a naturally occurring clay formed from the weathering of volcanic ash, primarily composed of montmorillonite. It possesses exceptional absorbent qualities, making it valuable in various applications. The clay is known for its swelling, viscosity, and adhesive properties, making it effective in drilling fluids, sealants, and as a natural binder in metals and ceramics.

The Rise of OEM Bentonite Clay Powder Factories

As industries seek specialized products tailored to their specific needs, OEM bentonite clay powder factories have emerged as vital players in the supply chain. These factories produce customized bentonite products designed to meet the unique specifications of their clients, ranging from formulation adjustments to packaging requirements.

The rise of OEM factories is driven by several factors

1. Customization Industries often require bentonite clay with specific characteristics. OEM factories have the flexibility to produce customized formulations that align with the precise needs of their clients. Whether it's for enhanced viscosity or improved absorption, these manufacturers can modify the clay processing techniques to achieve the desired outcomes.

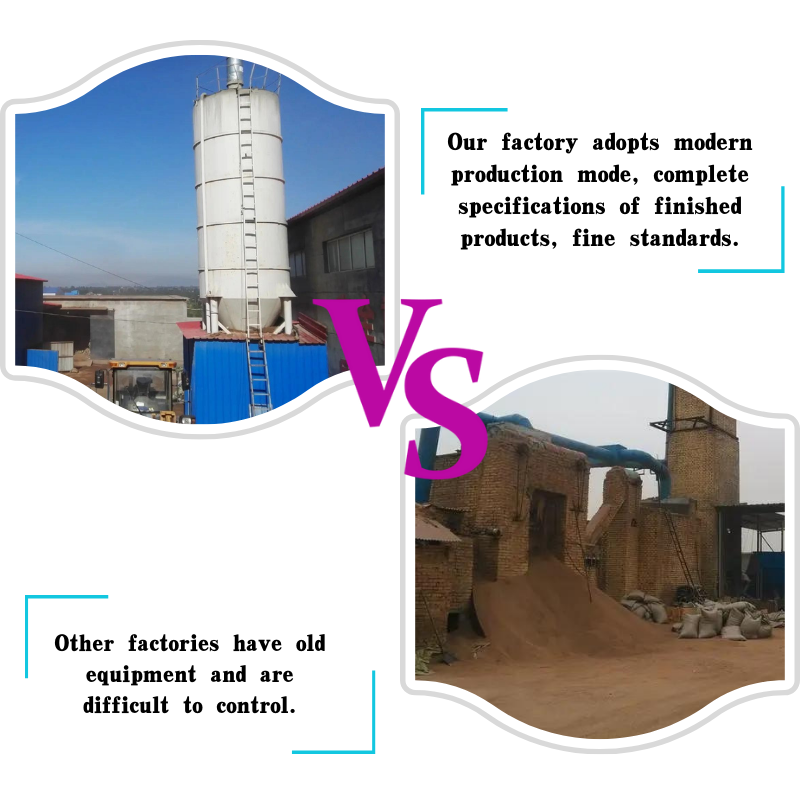

2. Quality Control OEM factories typically maintain stringent quality control measures, ensuring that each batch of bentonite clay powder meets industry standards. This focus on quality not only enhances product performance but also builds trust with clients who depend on consistent material properties for their applications.

3. Cost-efficiency By partnering with OEM factories, businesses can reduce production costs. These factories often leverage economies of scale and optimized manufacturing processes to deliver high-quality bentonite clay at competitive prices. This financial advantage is particularly appealing for companies aiming to maximize profitability while maintaining product quality.

4. Supply Chain Efficiency OEM factories streamline the supply chain by consolidating manufacturing processes. This efficiency enables quicker turnaround times and better inventory management, allowing clients to keep production running smoothly without unexpected delays.

Manufacturing Process of Bentonite Clay Powder

oem bentonite clay powder factories

The manufacturing of bentonite clay powder involves several steps, each critical in ensuring the clay meets the required specifications

. Here is a brief overview of the typical process1. Extraction Bentonite is mined from natural deposits, often using methods like open-pit mining. High-quality raw material is essential for producing superior clay powder.

2. Crushing and Milling After extraction, the bentonite is crushed and milled to achieve the desired particle size. This process enhances the clay's surface area, crucial for its absorbent and binding properties.

3. Modification and Treatment Depending on the final application, the bentonite may undergo chemical or thermal treatment to enhance its performance characteristics. This step is often tailored according to client specifications.

4. Quality Testing Rigorous quality testing is conducted to ensure compliance with industry standards and client requirements. Tests may include checking for purity, pH levels, and viscosity.

5. Packaging and Distribution Once the bentonite clay powder passes quality tests, it is packaged and prepared for distribution to clients worldwide.

Applications of Bentonite Clay Powder

The versatility of bentonite clay powder makes it suitable for a wide range of applications, including

- Construction Used as a binding agent in cement and as a waterproofing material. - Drilling Essential in the oil and gas industry as a component of drilling fluids. - Industrial Utilized in cat litter, as a filler in rubber and plastics, and as a clarifying agent in food processing. - Cosmetics Incorporated in skin care products for its absorbent and detoxifying properties.

Conclusion

OEM bentonite clay powder factories play a crucial role in the modern industrial landscape, providing tailored solutions that enhance product quality and efficiency. As the demand for specialized bentonite products continues to grow, these factories will remain essential partners in various sectors. Their ability to customize formulations, maintain quality, and streamline supply chains ensures that industries can rely on high-performance bentonite clay for their diverse applications.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025