OEM Activated Carbon Granules Production Facilities and Their Specialties

The Rise of OEM Activated Carbon Granules Factories

In recent years, the demand for activated carbon granules has surged globally, driven by the increasing need for air and water purification

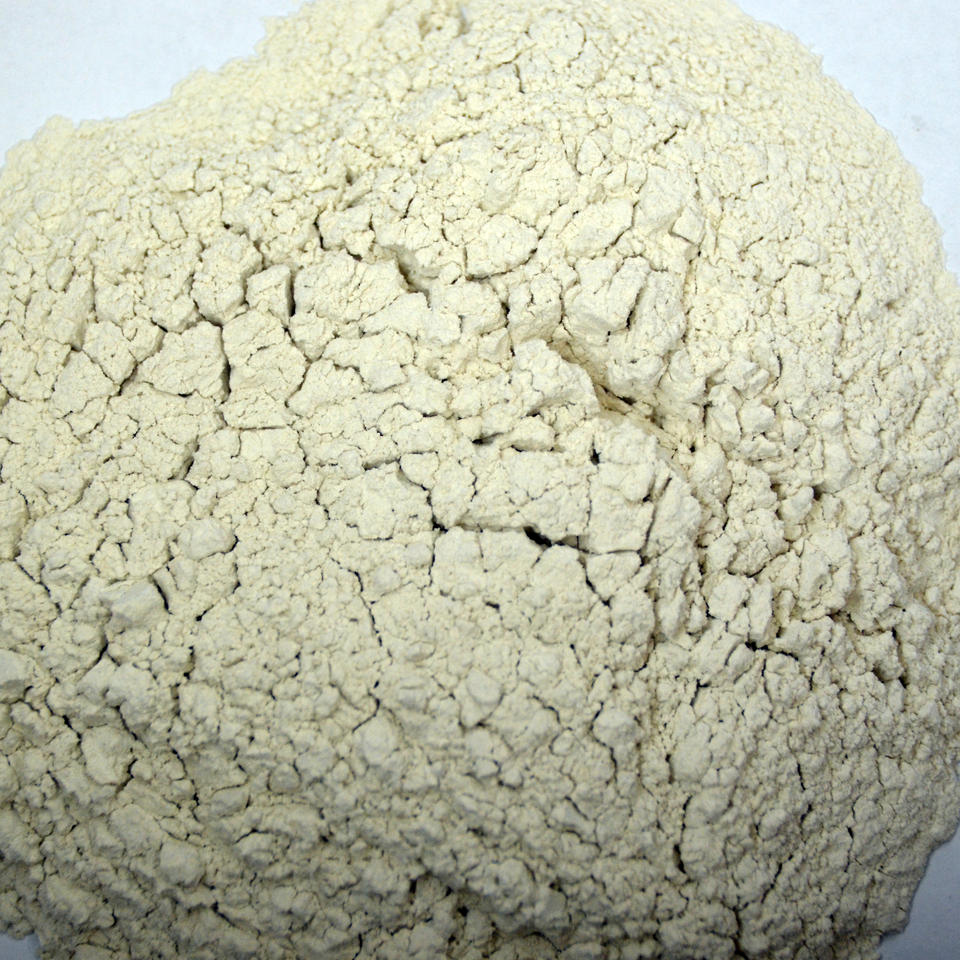

. Original Equipment Manufacturer (OEM) activated carbon granules factories have emerged as critical players in this growing market, emphasizing quality and customization to meet diverse industrial needs.Activated carbon granules are produced from carbonaceous materials through a process of pyrolysis and activation. This highly porous material is renowned for its exceptional adsorption properties, making it an effective solution for removing contaminants from gases and liquids. The uniqueness of OEM factories lies in their ability to produce activated carbon tailored to specific requirements, catering to various industries including water treatment, pharmaceuticals, food processing, and air purification.

One of the main advantages of OEM activated carbon granules factories is their ability to establish long-term partnerships with clients. These factories often work closely with their customers to understand their unique specifications and applications. By leveraging advanced technology and skilled expertise, OEM factories can create customized activated carbon solutions that maximize efficiency and performance. This personalized approach not only enhances customer satisfaction but also bolsters brand loyalty.

oem activated carbon granules factories

Moreover, the environmental sustainability of activated carbon production is gaining increasing attention. OEM factories are adopting eco-friendly practices, which include utilizing renewable resources and implementing efficient manufacturing processes. By prioritizing sustainability, these factories not only comply with regulatory requirements but also appeal to environmentally conscious consumers who prefer products that contribute to a greener planet.

In addition to customization and sustainability, quality control is another fundamental aspect that OEM activated carbon granules factories focus on. Implementing stringent quality assurance measures guarantees that the end products meet international standards and specifications. Regular testing and verification help ensure that the activated carbon granules maintain optimal adsorption capacities and meet performance benchmarks across various applications.

The growth of OEM activated carbon granules factories is also propelled by technological advancements in production methods. Innovations in steam activation and chemical activation processes have enabled factories to produce activated carbon with higher surface areas and porosities. As a result, this enhances the effectiveness of the granules in trapping impurities, making them more desirable for industrial use.

In conclusion, OEM activated carbon granules factories are at the forefront of meeting the rising global demand for high-quality activated carbon solutions. By focusing on customization, sustainability, quality control, and technological innovation, these factories not only enhance their own competitiveness but also contribute significantly to the health of our environment. As industries worldwide continue to prioritize purification methods, the role of these factories will only grow more critical in the years to come.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025