Jan . 28, 2025 00:52

Back to list

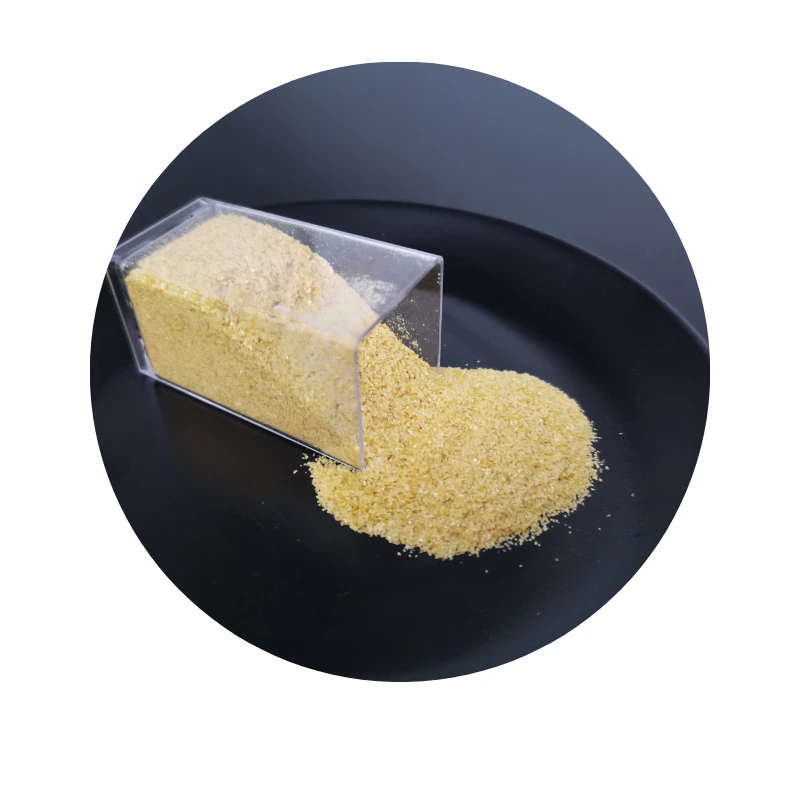

mica plates

Mica plates, though often overlooked in casual conversations, play a critical role in various industrial applications and consumer products. Their unique properties make them indispensable in areas ranging from electronics to heating appliances, offering unparalleled performance and reliability. In this article, we delve into the intriguing world of mica plates, uncovering the reasons behind their select usage and highlighting factors that contribute to their superior functionality.

Environmental considerations also underscore the importance of integrating mica plates in eco-conscious product design. Versatility in recycling and low-impact extraction processes accentuates mica as a sustainable choice. Unlike many synthetic insulators, mica's natural abundance and ease of processing reduce the environmental footprint associated with its production and disposal. In terms of innovation, the future of mica plates looks promising. Recent advancements in composite materials have led to the development of enhanced mica derivatives with even greater thermal and electrical stability. These improvements open doors to new applications, including advanced nanotechnology and green energy solutions such as solar panels and wind turbines. Industry experts anticipate exponential growth in these areas, predicting that mica plates will continue to push the boundaries of technological advancement. For businesses and consumers alike, understanding the properties and benefits of mica plates is critical in making informed decisions. Suppliers with proven expertise, such as offering detailed compliance certifications and transparent sourcing practices, stand out as trustworthy partners. Engaging with knowledgeable professionals who can provide bespoke advice further heightens the assurance and success of integrating mica solutions in specific projects. In conclusion, mica plates represent a fascinating intersection of nature's ingenuity and human engineering. Their substantial role across diverse applications stands testament to their performance, reliability, and safety. As industries evolve and new challenges emerge, mica plates are poised to remain pivotal in driving sustainable progress and technological excellence. Embracing their use not only elevates standards but also reflects a commitment to leveraging materials that embody both performance and responsibility.

Environmental considerations also underscore the importance of integrating mica plates in eco-conscious product design. Versatility in recycling and low-impact extraction processes accentuates mica as a sustainable choice. Unlike many synthetic insulators, mica's natural abundance and ease of processing reduce the environmental footprint associated with its production and disposal. In terms of innovation, the future of mica plates looks promising. Recent advancements in composite materials have led to the development of enhanced mica derivatives with even greater thermal and electrical stability. These improvements open doors to new applications, including advanced nanotechnology and green energy solutions such as solar panels and wind turbines. Industry experts anticipate exponential growth in these areas, predicting that mica plates will continue to push the boundaries of technological advancement. For businesses and consumers alike, understanding the properties and benefits of mica plates is critical in making informed decisions. Suppliers with proven expertise, such as offering detailed compliance certifications and transparent sourcing practices, stand out as trustworthy partners. Engaging with knowledgeable professionals who can provide bespoke advice further heightens the assurance and success of integrating mica solutions in specific projects. In conclusion, mica plates represent a fascinating intersection of nature's ingenuity and human engineering. Their substantial role across diverse applications stands testament to their performance, reliability, and safety. As industries evolve and new challenges emerge, mica plates are poised to remain pivotal in driving sustainable progress and technological excellence. Embracing their use not only elevates standards but also reflects a commitment to leveraging materials that embody both performance and responsibility.

Share

Next:

Latest news

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025