Ground Calcium Carbonate Providers for Quality Industrial Applications and Products

Ground Calcium Carbonate Suppliers An Overview

Ground calcium carbonate (GCC) is a crucial ingredient utilized across various industries for its versatility and multifaceted applications. As a naturally occurring mineral, calcium carbonate is derived from limestone, marble, and chalk through a process of grinding and refining. This white powder is extensively used in construction, agriculture, plastics, paints, and various industrial applications. The suppliers of GCC play a pivotal role in ensuring that industries receive this essential material in the required quality and quantity.

Understanding Ground Calcium Carbonate

Ground calcium carbonate is characterized by its high purity levels and particle size distribution, which can be tailored to meet specific application needs. GCC is known for its ability to improve the hardness, gloss, and opacity of products. Additionally, it acts as a filler material, providing bulk and strength while being cost-effective.

In the construction industry, GCC serves several purposes. It is commonly used in cement and concrete production, enhancing the mixture's properties and ultimately contributing to more durable structures. In the agricultural sector, GCC is utilized as a soil conditioner and pH balancer, promoting plant growth by enhancing nutrient availability. Furthermore, GCC finds its way into paint formulations, where it serves as a white pigment and enhances the coating's quality and durability.

The Role of Suppliers

The demand for ground calcium carbonate has surged in recent years, prompting a significant increase in the number of suppliers in the market. Suppliers of GCC range from large multinational corporations to smaller local companies, each offering a diverse range of products and services. The choice of supplier can significantly impact the quality of the end product, making it crucial for industries to select reliable and reputable partners.

When evaluating ground calcium carbonate suppliers, several factors should be considered

1. Quality Assurance A reputable supplier should provide products that meet stringent quality standards. This includes adhering to specifications set by industry organizations and ensuring that the GCC is free from impurities.

ground calcium carbonate suppliers

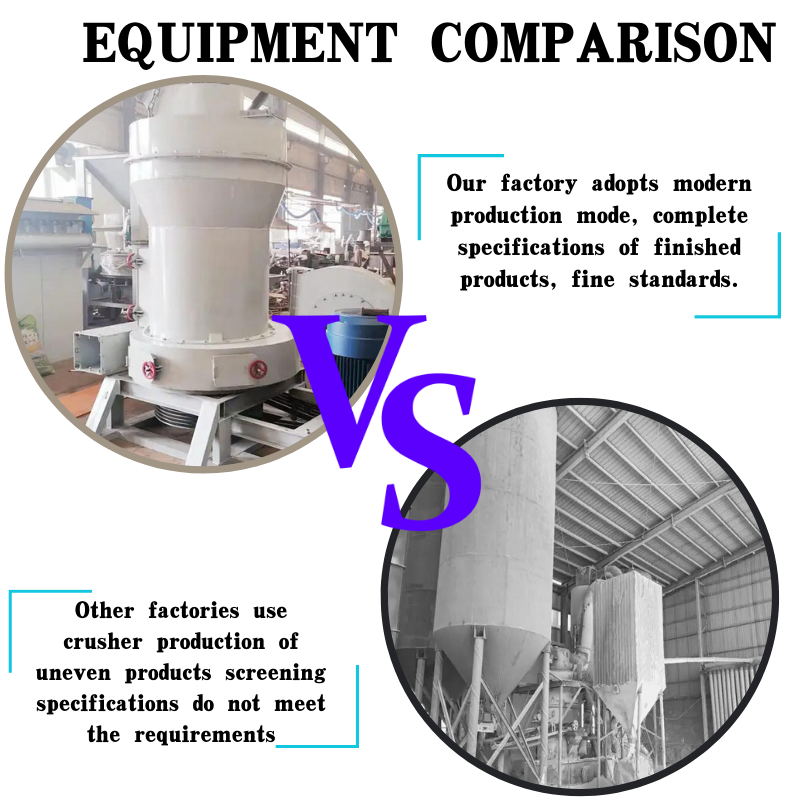

2. Production Capabilities Suppliers differ in terms of their production capabilities. Companies that operate modern, efficient facilities may offer a more consistent quality and a broader range of particle sizes, which can be tailored to specific application requirements.

3. Supply Chain Reliability The ability to deliver products on time is vital for many industries. Suppliers that maintain an efficient logistics network can ensure timely delivery, thus preventing production delays for their clients.

4. Technical Support and Consultation Many manufacturers benefit from technical support offered by GCC suppliers. This could include guidance on product selection, application techniques, or formulation advice to maximize the effectiveness of the calcium carbonate used.

5. Sustainability Practices As environmental consciousness grows, many businesses are now prioritizing suppliers that adhere to sustainable practices. This may include sourcing materials responsibly, reducing waste, and minimizing carbon footprints during production.

Market Trends

The ground calcium carbonate market has been influenced by several trends, including the rise of environmentally friendly materials and practices in manufacturing. Many consumers are now demanding eco-friendly products, prompting industries to explore natural and sustainable alternatives like GCC.

Additionally, advancements in technology have resulted in the development of better processing techniques, leading to higher-quality products and the ability to meet more specialized customer needs. This evolving landscape continues to reshape supplier dynamics, fostering competition and innovation.

Conclusion

Ground calcium carbonate suppliers play an integral role in various sectors by providing essential materials that contribute to product quality and performance. With the industry's increasing demand for high-quality GCC, selecting the right supplier becomes a critical factor for businesses aiming for success. By focusing on quality assurance, production capabilities, supply chain reliability, technical support, and sustainability, companies can forge strong partnerships with suppliers and ensure optimal outcomes for their products and applications. As the market continues to evolve, the collaboration between manufacturers and suppliers will remain vital in meeting the challenges and demands of the future.

Share

-

Premium Ceramsite for Plants & Hydroponics - Ideal Growing MediaNewsAug.10,2025

-

Premium Mineral Sepiolite Powder: Versatile Adsorbent & FillerNewsAug.09,2025

-

Premium Talcum Powder - Smoothness & Purity GuaranteedNewsAug.08,2025

-

Premium Fly Ash Powder: Ideal Admixture for Strong ConcreteNewsAug.07,2025

-

Premium Pine Bark Mulch: Nuggets & Shredded StylesNewsAug.06,2025

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025