Glass Beads for Sandblasting Production and Suppliers Overview

Glass Beads for Sandblasting An Overview of Manufacturers and Their Benefits

In the realm of surface preparation and finishing, sandblasting has emerged as a versatile and highly efficient technique. Among the materials used for sandblasting, glass beads have gained considerable attention due to their unique properties and advantages. The glass beads for sandblasting are produced by several manufacturers, each aiming to provide high-quality products that meet industry standards. This article explores the key features of glass beads and the role of manufacturers in this essential marketplace.

What Are Glass Beads?

Glass beads are small, spherical particles made from high-quality glass, often utilized in sandblasting applications. Their smooth and round structure allows for effective surface treatment without causing significant damage to the substrate being processed. Unlike traditional abrasive materials such as sand, glass beads are non-toxic and environmentally friendly, making them an excellent choice for various applications, including cleaning, finishing, and etching surfaces.

Advantages of Glass Beads for Sandblasting

One of the primary reasons for the increasing popularity of glass beads is their ability to provide a superior finish. They produce a clean, bright, and uniform surface ideal for various industries, including automotive, aerospace, and metalworking. Here are some of the key advantages of using glass beads for sandblasting

1. Minimal Substrate Damage Glass beads are less abrasive than other materials, meaning they can clean or finish surfaces without causing harm. This is particularly beneficial when working with delicate substrates or parts that require precision finishing.

2. Reusability Glass beads can often be reused multiple times before needing to be replaced. This not only reduces the operational costs associated with sandblasting but also lessens environmental impact.

glass beads for sandblasting manufacturers

4. Versatile Applications Glass beads are suitable for a wide range of applications. From removing paint and rust to preparing surfaces for coating, these versatile abrasives can be employed across multiple sectors.

The Role of Manufacturers

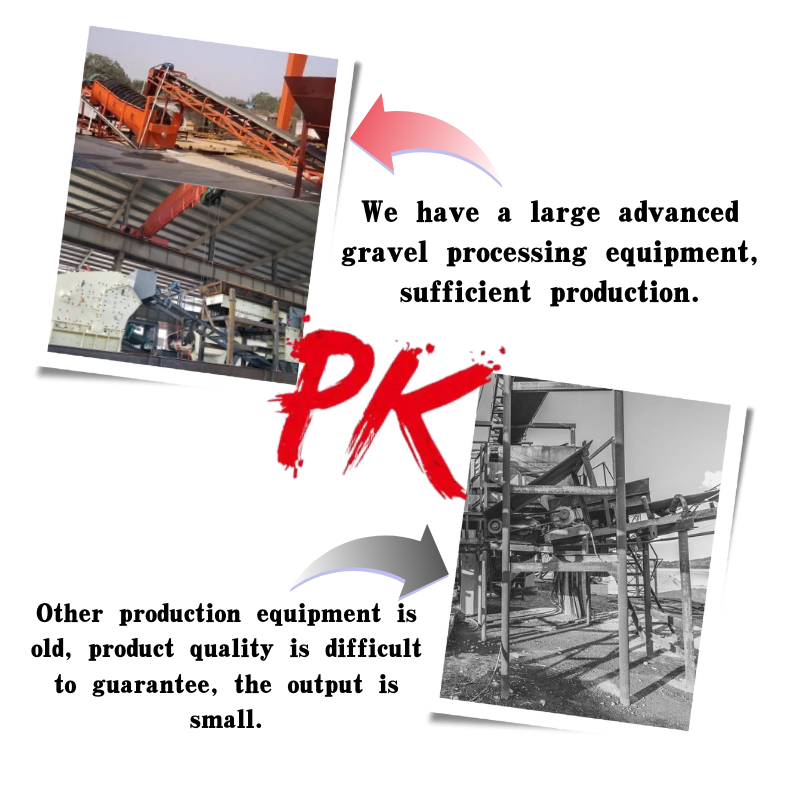

The production and distribution of glass beads for sandblasting is a specialized field, with numerous manufacturers investing in technology and innovation to ensure top-quality products. Leading manufacturers are focused on producing glass beads that meet stringent industry standards for size, hardness, and cleanliness.

1. Quality Control The best manufacturers implement rigorous quality control measures to ensure that their glass beads meet specifications. Batch consistency is essential, as variances in size or composition can affect the outcomes of sandblasting operations.

2. Customization Some manufacturers offer customized glass beads tailored to specific applications or customer requirements. By adjusting factors such as bead size and chemical composition, manufacturers can provide solutions that better meet the needs of particular industries.

3. Research and Development To stay competitive, manufacturers are increasingly investing in research and development. Innovations might include developing new glass formulations or improving production techniques to enhance performance and reduce costs.

4. Customer Support and Training Knowledgeable manufacturers also provide customer support and training services. By partnering with businesses in the sandblasting industry, they can help clients optimize their processes and achieve the best possible results using glass beads.

Conclusion

Glass beads for sandblasting represent a significant advancement in surface preparation technology. Their numerous advantages make them a preferable choice over traditional abrasives. With a robust market presence, dedicated manufacturers are committed to producing high-quality glass beads and supporting their customers. As industries continue to evolve, the role of glass beads in sandblasting will likely expand, creating opportunities for manufacturers and end-users alike. Whether for cleaning, finishing, or preparing surfaces, glass beads stand out as a reliable, effective, and environmentally friendly option in the sandblasting landscape.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025