Effective Use of Fly Ash in Concrete Production for Enhanced Sustainability and Strength

The Role of Fly Ash in Concrete Manufacturing

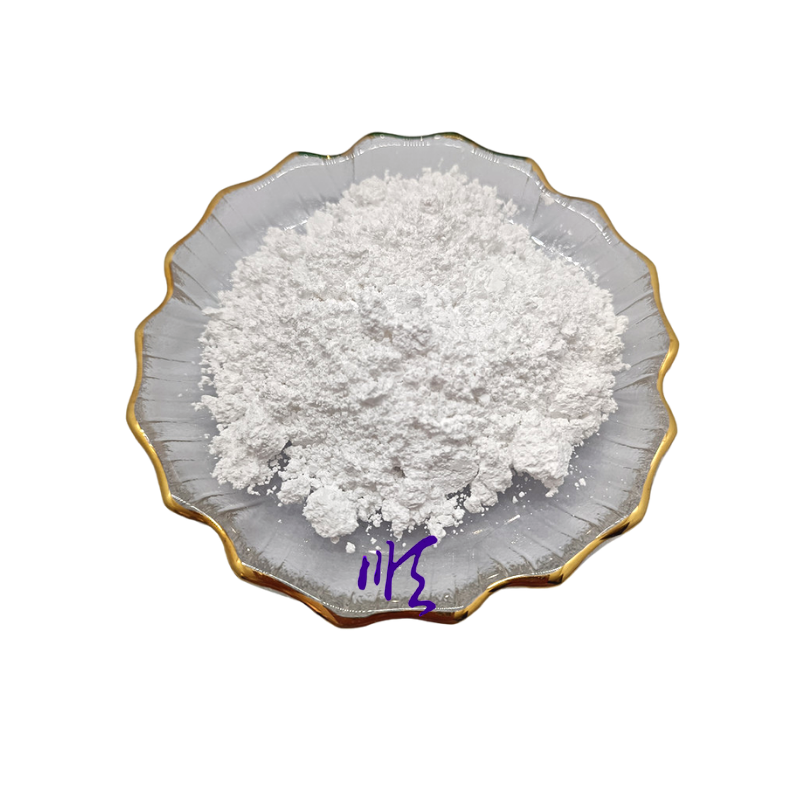

Fly ash, a byproduct of coal combustion in power plants, has gained significant attention in the construction industry for its application in concrete manufacturing. This fine, powdery material not only contributes to the sustainability of construction practices but also enhances the properties of concrete, making it a favorable alternative to traditional cement.

Understanding Fly Ash

Fly ash consists of tiny glassy spheres that are formed when the combustion of pulverized coal occurs. Most of this byproduct is disposed of in landfills; however, its utilization in concrete production represents a shift towards more sustainable construction methodologies. There are two main classes of fly ash used in concrete manufacturing Class F and Class C. Class F fly ash, produced from anthracite or bituminous coal, is characterized by its high silica content. On the other hand, Class C fly ash, derived from lignite or sub-bituminous coal, contains more lime and is known for its cementitious properties.

Benefits of Fly Ash in Concrete

1. Sustainability One of the primary advantages of using fly ash in concrete is its contribution to sustainability. By incorporating fly ash, manufacturers can reduce the reliance on Portland cement, which is known for its high carbon footprint. The production of cement contributes approximately 8% of global CO2 emissions. Thus, using fly ash helps in lowering the overall environmental impact of concrete.

2. Improved Workability Fly ash improves the workability of concrete. The spherical particles of fly ash create a more fluid mixture, making it easier to handle and manipulate. This enhanced workability can lead to better finishing and reduced labor costs during construction.

3. Strength Development Although fly ash is not a direct substitute for cement, its pozzolanic properties allow it to react with lime in the presence of moisture. This reaction contributes to the strength development of concrete over time. Concrete containing fly ash often shows improved long-term strength characteristics compared to conventional concrete.

fly ash for concrete manufacturers

4. Durability Fly ash enhances the durability of concrete by reducing permeability, which is crucial for protecting against environmental factors such as sulfate attack, chloride intrusion, and alkali-silica reaction. Additionally, concrete with fly ash tends to have a lower heat of hydration, which minimizes cracking during the curing process, especially in large structural elements.

5. Cost Efficiency Incorporating fly ash into concrete mixtures can be a cost-effective solution for manufacturers. Since fly ash is often less expensive than traditional cement, its use can lead to reduced material costs. Moreover, the potential for longer-lasting structures translates to lower maintenance costs over time.

Challenges in Using Fly Ash

While the benefits of using fly ash are substantial, there are some challenges that manufacturers may face. The quality of fly ash can vary significantly based on its source and handling practices. Consistent performance in concrete requires careful selection and quality control of the fly ash used. Additionally, some regulatory standards may limit the incorporation levels of fly ash in concrete mixes, necessitating compliance with these regulations.

Another challenge is the perception within the industry. Some stakeholders may be hesitant to adopt fly ash due to misconceptions about its performance or concerns regarding variability. Educating manufacturers, engineers, and clients about the established benefits and successful case studies can help alleviate these concerns and promote wider acceptance.

Conclusion

Fly ash is an invaluable material in the concrete manufacturing industry, providing a range of benefits that align with contemporary goals of sustainability and performance enhancement. As the construction sector continues to grapple with environmental concerns, the adoption of fly ash represents a forward-thinking approach that not only conserves resources but also leads to improved material properties. By addressing the challenges and increasing awareness, fly ash can play a key role in the future of sustainable concrete production, paving the way for more eco-friendly building practices. As the industry evolves, ongoing research and innovation will further unlock the potential of fly ash, ensuring its place in the concrete landscape for years to come.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025