Exploring Titanium Dioxide Production in China for PAI Applications Trends and Innovations Ahead

China's Titanium Dioxide Production for the PAI Industry An Overview

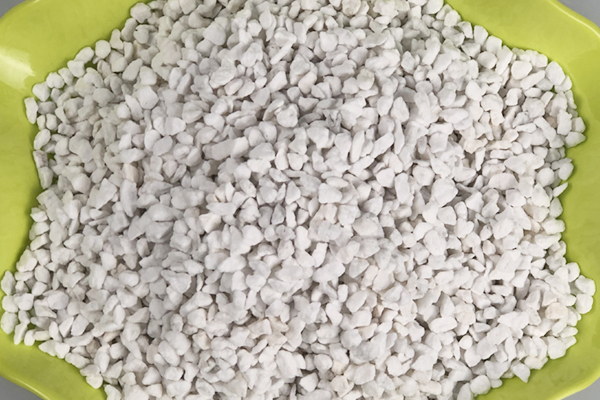

Titanium dioxide (TiO2) has become an essential compound in various industries, notably in coatings, plastics, and the production of pigments. One of the significant applications of titanium dioxide is in the production of Polyamide Imide (PAI), a high-performance polymer known for its excellent thermal stability, mechanical strength, and chemical resistance. As the demand for PAI continues to rise, particularly in automotive, aerospace, and electronics sectors, China has emerged as a leading producer of titanium dioxide to support this expanding industry.

China's titanium dioxide manufacturing is characterized by its scale and technological advancements. With numerous state-of-the-art factories spread across the country, Chinese manufacturers are capable of producing a vast amount of TiO2 to meet both domestic and international demands. The production processes have evolved over the years, moving towards more sustainable and environmentally friendly methods. This development is crucial as the traditional manufacturing processes for titanium dioxide have faced scrutiny due to their environmental impact.

China's Titanium Dioxide Production for the PAI Industry An Overview

Chinese factories have made substantial investments in modernizing their facilities to adopt the chloride process, thereby increasing the production efficiency and reducing the ecological footprint. Furthermore, automation and advanced monitoring systems are enhancing the quality control of TiO2 production, ensuring that the end product meets the stringent requirements needed for applications in PAI. As a result, manufacturers can deliver titanium dioxide that not only meets performance standards but also complies with global environmental guidelines.

china titanium dioxide for pai. factory

In terms of application, titanium dioxide plays a crucial role in the production of PAI by providing essential properties that enhance the material's performance. TiO2 is valued for its ability to improve the thermal and mechanical properties of PAI, making the final product suitable for high-temperature applications. Additionally, it acts as a reinforcing agent, which further increases the durability and lifespan of PAI components.

The demand for PAI is expected to grow as industries look for high-performance materials that can withstand extreme conditions. With sectors such as automotive focusing on lightweight and fuel-efficient solutions, the need for advanced polymers like PAI reinforced with titanium dioxide will only increase. This surge in demand places immense pressure on titanium dioxide producers to not only increase output but also innovate and maintain high-quality standards.

China's strategic position in the global titanium dioxide market is solidified by its comprehensive supply chain, from raw mineral extraction to sophisticated manufacturing processes. The presence of abundant raw materials like ilmenite and rutile, combined with competitive labor costs, offers Chinese TiO2 manufacturers a unique advantage.

In conclusion, as the world moves towards more sustainable industrial practices, China's titanium dioxide factories are at the forefront of producing high-quality TiO2 for various applications, particularly in the PAI industry. By investing in cleaner and more efficient production methods, these manufacturers are poised to meet both current and future demands, solidifying China’s role as a global leader in titanium dioxide production. The balance between economic growth and environmental stewardship will define the future landscape of this important industry.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025