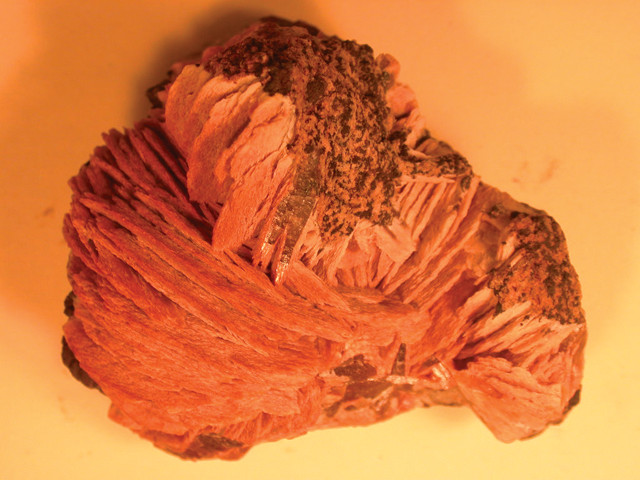

custom zeolite crystal

Custom Zeolite Crystals A Comprehensive Overview

Zeolites are naturally occurring or synthetic aluminosilicate minerals that have garnered significant attention due to their unique porous structures and ion-exchange properties. Their applications range from water purification to catalysis, making them invaluable in various industries. The term custom zeolite crystal refers to the tailored synthesis of zeolite materials to meet specific application requirements, offering unprecedented flexibility and efficiency in their use.

Understanding Zeolites

Zeolites are characterized by their crystalline nature and uniform pores, typically ranging from 0.3 to 1 nanometer in diameter. This size allows them to selectively adsorb molecules, making them ideal for processes like gas separation, ion exchange, and catalysis. Natural zeolites can be found in volcanic ashes and sedimentary rocks, while synthetic zeolites are created through hydrothermal processes and provide the ability to customize their properties for specialized uses.

The Importance of Customization

Custom zeolite crystals present a significant advantage over their naturally occurring counterparts. While natural zeolites possess fixed structural and chemical properties, custom synthesis allows for adjustments in framework composition, pore size, and ionic content. This tailoring can enhance specific properties, such as selectivity, adsorption capacity, and thermal stability, leading to improved performance in various applications.

For instance, in the field of catalysis, custom zeolites can be designed to enhance catalytic activity for specific reactions, thereby increasing efficiency and reducing unwanted byproducts. Additionally, in the realm of environmental remediation, custom zeolites can be synthesized to target particular pollutants, enhancing the effectiveness of wastewater treatment processes.

Synthesis Techniques

custom zeolite crystal

The synthesis of custom zeolite crystals typically involves several methods, including hydrothermal synthesis, sol-gel processes, and template-directed synthesis. Hydrothermal synthesis is the most commonly used method, where an aqueous solution containing silicon and aluminum sources is subjected to high temperature and pressure, leading to the formation of zeolite crystals. The composition of the initial solution can be modified to achieve the desired zeolite type and properties.

Another innovative approach is the use of organic templates, which guide the formation of the zeolite structure. By altering the template's chemical structure, researchers can influence the resulting zeolite’s pore size and morphology, paving the way for the production of novel zeolite materials with enhanced performance characteristics.

Applications of Custom Zeolite Crystals

The versatility of custom zeolite crystals allows for a wide range of applications across different sectors. In the petroleum industry, custom zeolites serve as catalysts for cracking processes, enhancing the yield of lighter hydrocarbons. In environmental applications, they are used in filters to remove heavy metals and contaminants from water sources. Moreover, in agriculture, custom zeolites can improve nutrient retention and prevent leaching, contributing to sustainable farming practices.

In the context of greenhouse gas reduction, custom zeolites can be employed in carbon capture technologies. Their ability to selectively adsorb CO2 makes them suitable for capturing emissions from industrial processes, thus playing a crucial role in combating climate change.

Conclusions

Custom zeolite crystals represent a frontier in material science with significant implications across various industries. Their unique properties, coupled with the ability to tailor them for specific applications, make them essential for innovative solutions to contemporary challenges. As research and development in this field continue to advance, we can expect to see even broader applications and increased efficiency from custom zeolite materials. The future of zeolite technology appears bright, promising enhanced capabilities to meet the world's evolving industrial and environmental needs.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025