custom volcanic rock stone factories

The Fascinating World of Custom Volcanic Rock Stone Factories

Volcanic rock, known for its unique properties and aesthetic appeal, has become increasingly popular in various industries, from construction to landscaping. Custom volcanic rock stone factories play a crucial role in this booming market, providing tailored solutions that meet the specific needs of clients around the globe. This article delves into the characteristics of volcanic rock, the processes behind its customization, and the implications of its widespread use.

What is Volcanic Rock?

Volcanic rock, or igneous rock, originates from the solidification of lava or magma. Its formation process yields various types of stone, such as basalt, pumice, and obsidian, each with distinct physical and chemical properties. This rock type is generally characterized by its durability, resistance to weathering, and unique textures and colors, making it a preferred choice for architects and designers.

One of the most noteworthy types of volcanic rock is basalt, known for its strength and versatility. It has been used in construction for decades, favored for its ability to withstand heavy loads, making it an ideal material for road construction, building facades, and even decorative features. Pumice, on the other hand, is lightweight and porous, often used in landscaping and gardening as a soil amendment due to its excellent drainage properties.

Customization in Volcanic Rock Production

Custom volcanic rock stone factories focus on producing personalized dimensions, shapes, colors, and finishes to cater to various project requirements. This level of customization not only enhances the visual appeal but also optimizes the functionality of the volcanic rock in different applications.

custom volcanic rock stone factories

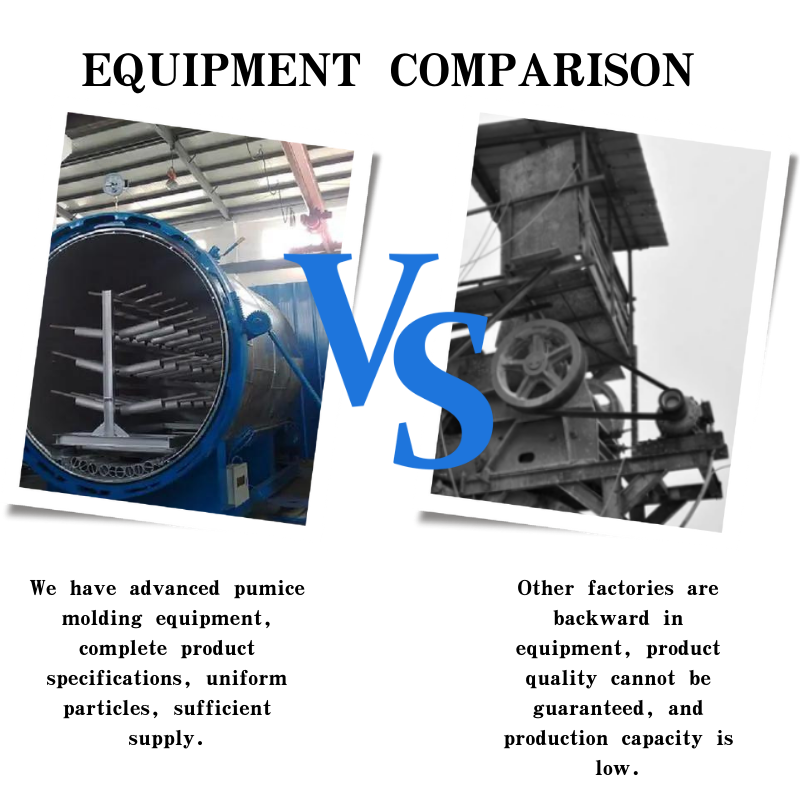

The process of customization begins with sourcing high-quality volcanic rock from reputable quarries. Factories use advanced technology such as Computer Numerical Control (CNC) machines and laser cutting methods to create precise shapes and sizes. Clients can specify their design preferences, including textures, patterns, and finishes, allowing for unique creations. For instance, a client may request polished basalt tiles for flooring in a modern high-rise building or rugged, natural-looking stones for a backyard garden.

Moreover, custom volcanic rock factories often collaborate closely with architects and designers. This partnership facilitates a more comprehensive understanding of the intended use of the volcanic stone, ensuring that the final product aligns perfectly with the project's vision. Customization can extend to color matching, where pigments are added to the stone in order to create a specific hue that complements the overall design theme.

Environmental and Economic Considerations

Utilizing volcanic rock derived from sustainable practices has significant environmental benefits. Since volcanic rock is abundant in many regions, responsible quarrying techniques minimize ecological impact. Furthermore, volcanic rock is often locally sourced, reducing transportation emissions and supporting local economies.

The economic implications of custom volcanic rock production are profound. By investing in custom stone solutions, businesses can differentiate themselves in a competitive market. Additionally, the growing trend toward sustainable building materials means that volcanic rock is becoming increasingly sought after, elevating its market value.

Conclusion

In summary, custom volcanic rock stone factories represent a dynamic sector that combines natural beauty with functional design. By offering tailored solutions, these factories not only meet the diverse needs of their clients but also promote environmentally sustainable practices. Whether you are an architect, contractor, or homeowner, the allure of volcanic rock is undeniable. Its unique characteristics and customizable options provide endless possibilities for creating stunning, durable, and eco-friendly spaces. As the demand for volcanic rock continues to rise, so too will the innovations and creative applications that emerge from the factories dedicated to this fascinating material.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025