custom titanium dioxide rutile factory

Custom Titanium Dioxide Rutile Factory Harnessing Innovation for Superior Quality

In the ever-evolving world of materials science and manufacturing, titanium dioxide (TiO2) stands out as an essential pigment and a key ingredient in various industrial applications. Among the different forms of titanium dioxide, rutile is particularly prized for its superior opacity and brilliant whiteness, making it a staple in paints, coatings, plastics, and even food products. Establishing a custom titanium dioxide rutile factory can meet industry demands while pushing the boundaries of innovation and sustainability.

Understanding Titanium Dioxide and Rutile

Titanium dioxide exists mainly in two crystalline forms rutile and anatase. Rutile, characterized by its high refractive index and strong UV light absorption properties, is extensively used in applications requiring durability and longevity. Its unique properties make it ideal for enhancing the quality and performance of products while ensuring their longevity. Industries from paint and coatings to cosmetics and food processing heavily rely on this essential compound, opening avenues for businesses to thrive in its production.

The Significance of Custom Production

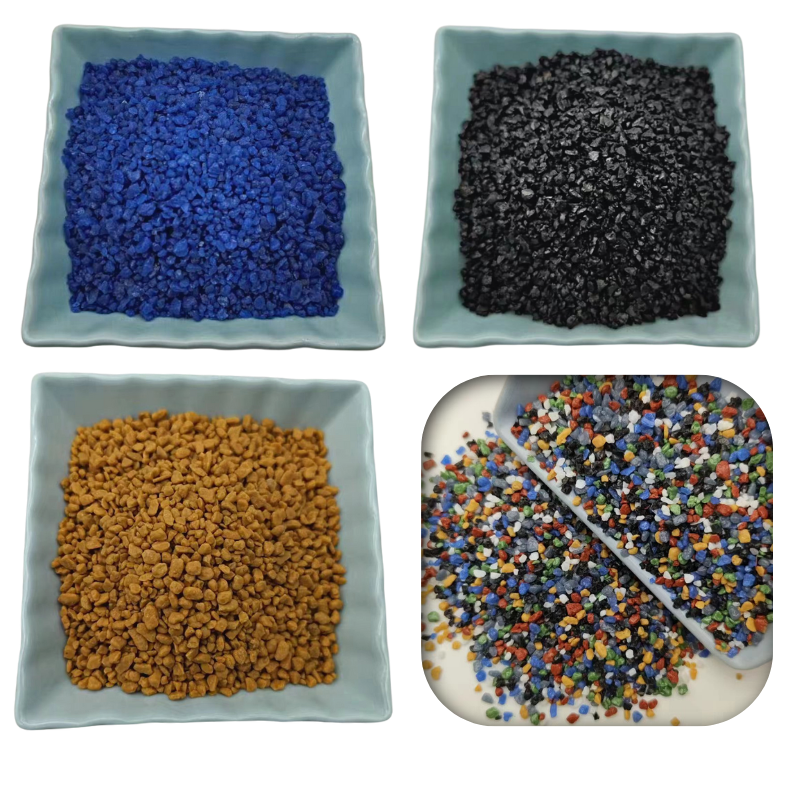

Custom titanium dioxide rutile factories emphasize tailored production processes to accommodate specific client needs. Instead of a one-size-fits-all approach, such factories invest in flexible technologies that allow for modifications in particle size, surface treatment, and formulation. This customization is crucial in meeting the diverse requirements of various sectors, ensuring optimal performance and satisfaction for clients.

For instance, in the paint industry, different formulations may be required based on the intended use (interior vs. exterior), application methods (spray vs. brush), and environmental conditions (humidity, temperature). A custom titanium dioxide rutile factory can adjust the tiO2 particle size to enhance dispersion, increase coverage, and improve durability, thus directly impacting the quality of the final product.

Investing in Quality Control and Technology

custom titanium dioxide rutile factory

The establishment of a custom titanium dioxide rutile factory demands a strong emphasis on quality control and cutting-edge technology. High-quality raw materials, combined with advanced manufacturing processes, ensure the final product meets stringent industry standards. This is essential in industries such as food and pharmaceuticals, where purity and safety are paramount.

Factories should implement rigorous testing protocols for every batch produced. Techniques such as X-ray diffraction, scanning electron microscopy, and spectrophotometry can be employed to analyze the chemical composition, particle-size distribution, and overall quality of titanium dioxide. By investing in state-of-the-art technology and quality assurance processes, a factory not only enhances its reputation but also builds long-term relationships with clients based on trust and reliability.

Sustainability in Production

In today's environmentally conscious market, establishing a custom titanium dioxide rutile factory also involves a commitment to sustainability. Finding environmentally friendly methods for the extraction and processing of titanium dioxide is crucial. Modern factories can employ innovative recycling processes to minimize waste, utilize renewable energy sources, and adopt more efficient usage of natural resources.

Furthermore, sustainable production practices can be a significant differentiator in a competitive market, attracting clients who prioritize environmental responsibility. The use of eco-friendly surface treatments can enhance product appeal without compromising performance. Thus, the factory not only caters to its clients but also contributes positively to the planet.

Conclusion

The establishment of a custom titanium dioxide rutile factory represents a robust opportunity for businesses looking to capitalize on the growing demand for high-quality TiO2. By focusing on customization, quality control, technology investment, and sustainable practices, such factories can lead the way in innovation and excellence within the industry. As sectors continue to evolve, those who adapt and innovate will not only succeed but also reshape the future of manufacturing and material science. The journey towards establishing this factory, while challenging, promises significant rewards in terms of profitability and market presence, signaling a bright future for all stakeholders involved.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025