custom silica fume suppilers

Custom Silica Fume Suppliers Meeting Specialized Needs

Silica fume, a byproduct of the silicon and ferrosilicon alloy production, is gaining recognition for its beneficial properties in concrete and other construction materials. Its pozzolanic nature, which allows it to react with calcium hydroxide in the presence of water, leads to a significant enhancement in the durability and strength of concrete. As industries continue to innovate, the demand for custom silica fume products is on the rise. This article delves into the importance of custom silica fume suppliers and how they cater to specialized requirements across various sectors.

The Role of Silica Fume in Construction

Silica fume is known for its ability to improve the mechanical properties of concrete, such as compressive strength and workability. It also reduces the permeability of concrete, making structures more resistant to environmental factors, such as chloride ingress and sulfates. This characteristic is particularly valuable in construction projects involving bridges, highways, and industrial floors where durability is paramount.

Custom silica fume suppliers focus on tailoring their products to meet specific project requirements. This may include adjustments to the chemical composition or variations in particle size distribution, allowing engineers and architects to optimize concrete mixes for unique applications. For instance, some projects may necessitate higher reactivity for quick setting times, while others may require formulations that enhance aesthetic properties.

Advantages of Working with Custom Suppliers

custom silica fume suppilers

1. Tailored Solutions Unlike generic silica fume products, custom suppliers can modify their offerings based on customer specifications. This level of customization ensures that end-users receive materials that perfectly align with their project needs, leading to optimal performance and reduced waste.

2. Technical Expertise Custom silica fume suppliers often employ knowledgeable professionals who can provide technical advice and support. These experts can assist in mix design, offer recommendations for usage, and help troubleshoot any challenges that may arise during the construction process.

3. Quality Assurance Reputable suppliers of custom silica fume prioritize quality control, ensuring that their products meet industry standards and regulatory requirements. This commitment to quality is crucial for maintaining the integrity of construction projects and for achieving long-lasting results.

4. Sustainability The use of silica fume contributes to sustainability in construction. Custom suppliers may also offer eco-friendly solutions that include recycled materials or lower emissions during production, helping builders to achieve green certifications.

Conclusion

The demand for silica fume in construction and other applications continues to grow, and custom silica fume suppliers play a pivotal role in this evolution. By providing tailored solutions, expert guidance, and a commitment to quality, these suppliers help ensure that projects not only meet but exceed expectations. As industries evolve, the collaboration between manufacturers and builders will innovate further, leading to even more advanced materials and techniques in construction. Investing in a reliable custom silica fume supplier is essential for any organization looking to enhance the quality and durability of their concrete and construction materials.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

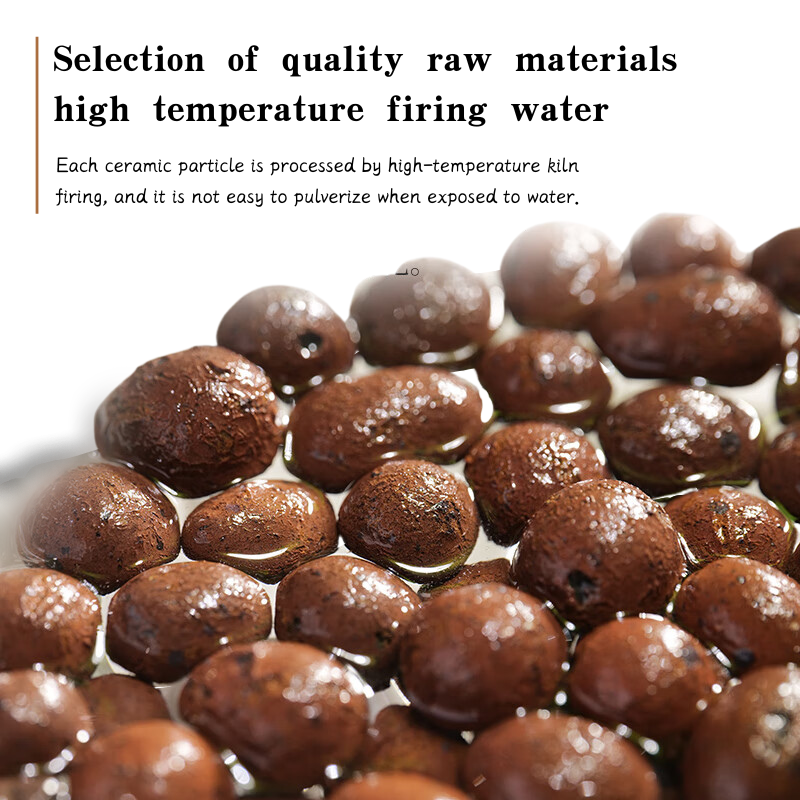

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025