custom quartz and mica factories

The Intricacies of Custom Quartz and Mica Factories

In the world of industrial manufacturing, quartz and mica have established themselves as essential materials across various sectors, including electronics, construction, and cosmetics. Custom quartz and mica factories have emerged to cater to the specific needs of these industries, providing tailor-made solutions that enhance product performance and aesthetics.

Quartz, a mineral composed of silicon and oxygen, is renowned for its hardness and resistance to chemical weathering. This makes it an invaluable resource in numerous applications, from countertops to industrial equipment. Mica, on the other hand, is a group of silicate minerals known for their perfect basal cleavage, allowing them to be split into thin sheets. Due to their innate properties, mica is widely used in electrical insulators, paint, and cosmetics.

The establishment of custom quartz and mica factories involves a meticulous process that begins with sourcing high-quality raw materials. Factories often collaborate with trusted suppliers to ensure that the minerals meet stringent quality standards. Once the materials are gathered, they undergo thorough testing to determine their suitability for various applications. This is a critical step that ensures the end products are both durable and efficient.

One of the primary advantages of custom quartz and mica factories is their ability to produce materials tailored to specific customer requirements. Clients may need particular colors, sizes, or properties that are unique to their applications. Employers in these factories use advanced technology and techniques to modify the minerals. For instance, quartz can be engineered to achieve enhanced clarity for aesthetic applications, while mica can be processed to exhibit specific thermal or electrical characteristics.

custom quartz and mica factories

In addition to customization, these factories also prioritize innovation. The demand for higher-performing materials requires constant research and development. Many manufacturers invest significantly in R&D to explore new methods of processing and utilizing quartz and mica. This leads to the development of advanced materials that are lighter, stronger, and more sustainable. For example, combining quartz with resin has produced composite materials that offer the beauty of natural stone with enhanced durability. Such innovations are pivotal in attracting new clientele and retaining existing customers.

Sustainability is another key focus for custom quartz and mica factories. As environmental concerns grow, manufacturers are compelled to adopt eco-friendly practices. This includes sourcing materials responsibly, reducing waste during manufacturing, and implementing recycling initiatives. Some factories have transitioned to using renewable energy sources, minimizing their carbon footprint and setting an example within the industry. Clients are increasingly looking for partners who prioritize sustainability, making this a crucial aspect of modern manufacturing.

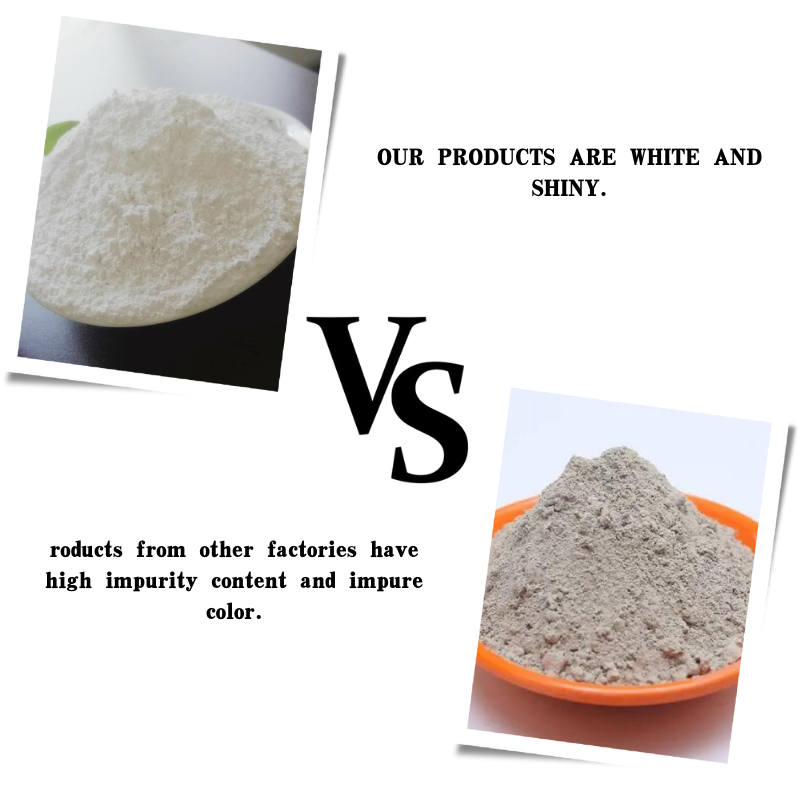

Quality control also plays a vital role in the operations of custom quartz and mica factories. Each batch of material produced undergoes rigorous testing to ascertain its properties and quality. This dedication to maintaining high standards ensures that clients receive reliable products that perform as expected. Such attention to quality not only builds trust with customers but also enhances the factory's reputation in a competitive market.

In conclusion, custom quartz and mica factories are at the forefront of material innovation and customization. By focusing on quality, sustainability, and constant improvement, these factories fulfill the diverse needs of various industries. As technology advances and demands evolve, the role of these factories will continue to grow, shaping the future of manufacturing and providing the necessary resources to meet evolving industry challenges. Whether in electronics or beauty products, the impact of custom quartz and mica manufacturing is profound and far-reaching.

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025