Custom Manufacturing Solutions for Micro Silica Fume Production Facilities

Custom Micro Silica Fume Factories Harnessing the Power of Advanced Materials

Micro silica fume, also known as silica dust or micro silica, is a byproduct of producing silicon and ferrosilicon alloys, primarily used in the construction and materials industries. It consists of very fine particles that enhance the properties of concrete and other materials. With the growing demand for high-performance concrete and sustainable construction practices, custom micro silica fume factories have emerged as essential players in the material supply chain. This article explores the significance of these factories and the innovation they bring to the industry.

Understanding Micro Silica Fume

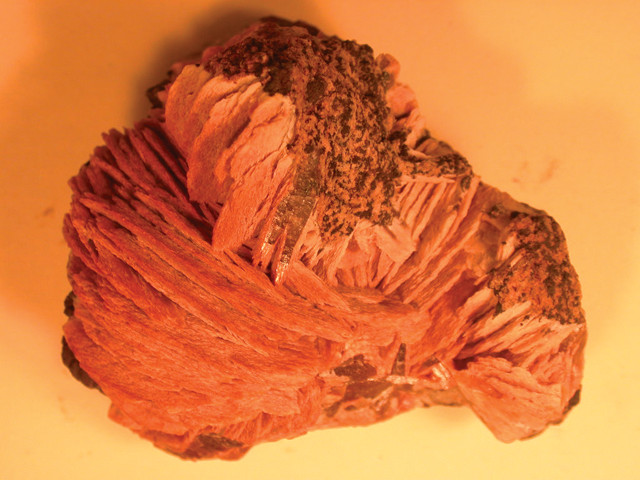

Micro silica fume is composed of amorphous silicon dioxide. Its particles are approximately 100 times smaller than that of ordinary cement, which allows for a high surface area that significantly improves the mechanical and durability properties of concrete. When added to concrete mixtures, micro silica fume helps in reducing permeability, increasing compressive strength, and enhancing resistance to chemical attacks, making it a desirable material for infrastructure projects.

The Rise of Custom Micro Silica Fume Factories

As the construction industry continues to evolve, the need for specialized materials has led to the establishment of custom micro silica fume factories. These facilities are designed to produce silica fume tailored to specific requirements of contractors and projects. Factors such as particle size, purity, and chemical composition can be adjusted to meet the unique demands of various applications, from skyscrapers to bridges and underground structures.

The customization aspect is crucial because different regions and projects have varying climatic conditions and engineering requirements. For instance, urban environments with high exposure to moisture may require silica fume with enhanced water resistance properties, whereas industrial projects might necessitate higher thermal resistance. Custom factories allow for on-demand production that can adapt to these unique specifications.

Production Processes in Custom Factories

The production process of micro silica fume involves several sophisticated steps. Initially, silicon metal is produced from quartz and carbon at high temperatures in submerged arc furnaces. The fumes generated during this process, primarily consisting of amorphous silicon dioxide, are collected using advanced filtration and cyclone systems.

custom micro silica fume factories

In a custom factory, these raw fumes can undergo further processing to enhance their properties. This may include size classification, where particles are sorted based on their dimensions, or purification processes to remove unwanted contaminants. Manufacturing facilities often implement state-of-the-art technologies to ensure quality control at every stage, ensuring that the final product meets strict industry standards.

Environmental Considerations

Custom micro silica fume factories are not only about meeting demand; they also play a vital role in promoting sustainability. The use of micro silica fume in concrete helps to reduce the environmental impact of construction. By replacing a portion of cement in concrete mixtures, silica fume contributes to lower carbon emissions, as cement production is a significant source of greenhouse gas emissions.

Furthermore, custom factories are increasingly adopting eco-friendly practices, such as waste reduction, energy efficiency, and recycling processes. Many facilities employ closed-loop systems to minimize waste and ensure that byproducts are reintroduced into the production cycle, thus emphasizing a circular economy.

The Future of Custom Micro Silica Fume Production

As the world moves towards more sustainable construction methods, custom micro silica fume factories are poised to play a pivotal role in meeting these needs. The rise of green building certifications and standards means that the demand for high-performance materials like micro silica fume will only increase.

Moreover, advancements in technology, such as automation and artificial intelligence in manufacturing processes, can lead to enhanced productivity and efficiency in custom silica fume production. The ability to analyze data from production lines can help in refining processes, reducing costs, and improving product quality.

Conclusion

Custom micro silica fume factories represent a critical evolution in material production within the construction industry. By providing tailored solutions that enhance concrete performance and support sustainable practices, these facilities are not only meeting the demands of contemporary construction projects but also promoting a greener future. As the industry continues to innovate and adapt, the role of these specialized factories will undoubtedly grow, contributing to safer, more durable, and environmentally friendly infrastructure worldwide.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025