custom large bags of perlite factories

Understanding Custom Large Bags of Perlite A Key Component in Modern Horticulture

Perlite is a remarkable mineral that has become a staple in various industries, particularly in horticulture. Known for its lightweight, porous nature, perlite is often used in soil amendments, potting mixes, and as a hydroponic growing medium. With the rising demand for sustainable gardening and horticultural practices, factories producing custom large bags of perlite have emerged as vital suppliers to meet this growing need.

One of the primary advantages of using perlite is its ability to improve soil aeration and drainage. In traditional gardening, compacted soil can hinder root development, leading to poor plant growth and health. Perlite, when mixed with soil, creates air pockets, allowing roots to breathe and absorb nutrients more efficiently. This characteristic makes perlite an essential component for both professional growers and hobbyists aiming to cultivate healthy plants.

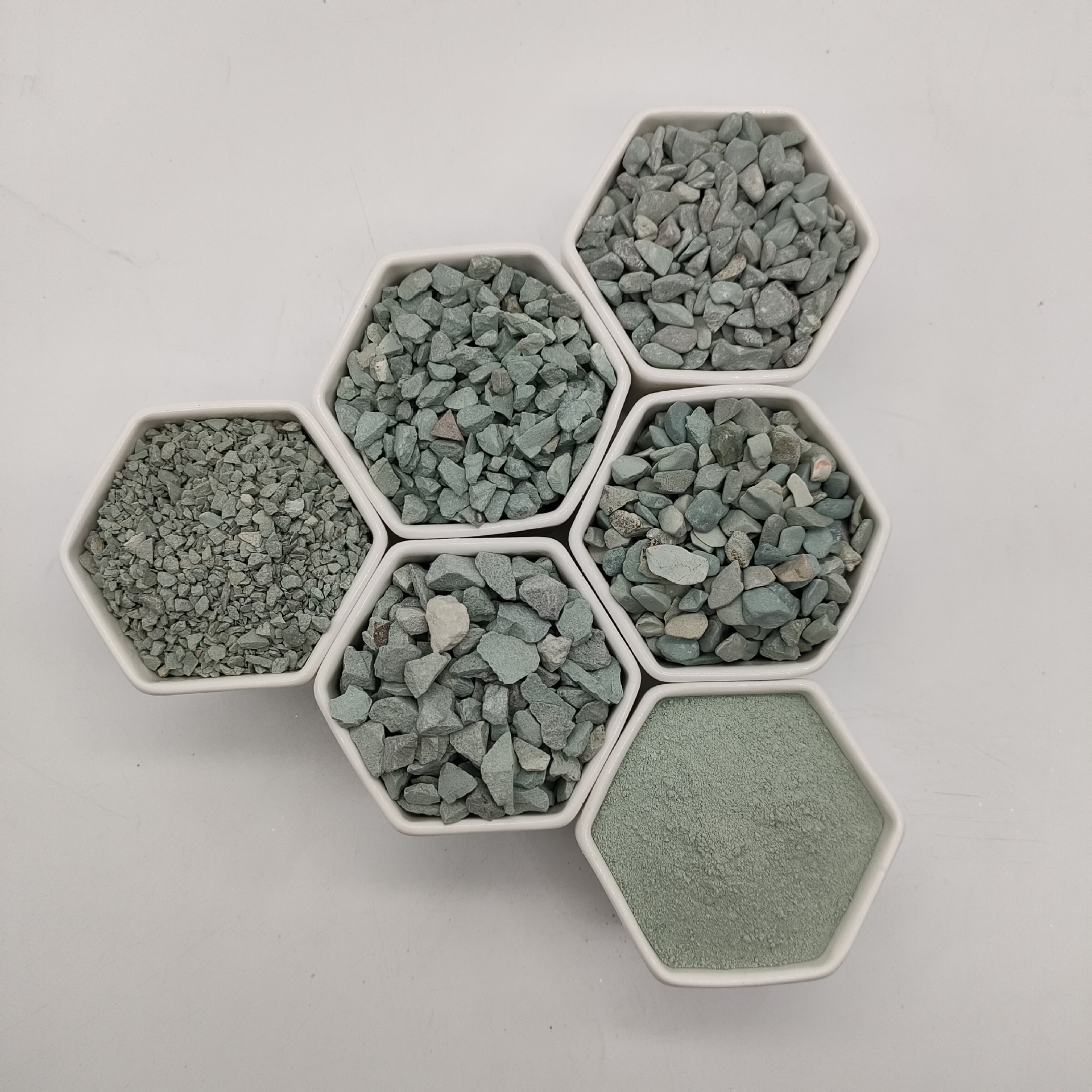

When it comes to the production of perlite, factories have begun to customize their offerings to cater to the diverse needs of their clients. Custom large bags of perlite can vary in size, ranging from 500 to 1500 liters or more, depending on the client's requirements. This flexibility allows growers to order the exact amount they need, reducing waste and ensuring that they have adequate supplies for their operations.

The production process of perlite typically involves heating raw volcanic glass to high temperatures, causing it to expand and become the lightweight, white aggregate that is widely recognized. This process not only creates the desired physical properties of perlite but also ensures that it is free from pathogens and contaminants. Factories focus on quality control to guarantee that every batch of perlite meets industry standards, offering growers peace of mind regarding the materials they use.

custom large bags of perlite factories

Additionally, eco-friendly practices are becoming more prominent in perlite production. Many factories are now adopting sustainable methods, such as recycling water used in the mining and processing stages. Moreover, the lightweight nature of perlite reduces transportation emissions, making it a more sustainable choice compared to heavier soil amendments.

Custom packaging solutions are also an essential feature provided by perlite factories. When ordering large bags of perlite, growers can choose from various options, such as UV-resistant materials to protect the contents from sunlight and deterioration. This customization ensures that the perlite maintains its integrity and effectiveness during storage and transport.

As the horticultural sector evolves, so do the applications of perlite. Beyond traditional gardening, it is now being used in innovative agricultural practices, such as vertical farming and hydroponics. The demand for perlite in these areas has prompted factories to scale up production and offer more specialized grades of perlite, tailored to specific growing requirements.

Moreover, the trend towards organic gardening has left a mark on the perlite industry. Many growers are seeking organic certifications for their growing mediums, and perlite, being naturally mined, fits well into this organic framework. Factories are responding to this demand by ensuring that their perlite complies with the necessary organic standards, thus appealing to a broader customer base.

In conclusion, custom large bags of perlite have become increasingly important in the horticulture industry. With its ability to enhance soil properties, its eco-friendly production processes, and the flexibility in packaging options, perlite remains a key ingredient for successful plant cultivation. As the industry continues to innovate and evolve, factories that specialize in perlite are poised to play a crucial role in supporting sustainable horticultural practices worldwide. This commitment to quality and customization not only benefits growers but also contributes to the overall health and vigor of the plants that depend on this versatile mineral.

Share

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025