Tailored Fly Ash Solutions for Concrete Production by Leading Manufacturers

Custom Fly Ash for Concrete Manufacturers Enhancing Quality and Sustainability

In the world of concrete manufacturing, the drive for enhanced performance and sustainability is more pressing than ever. One of the most significant innovations in this arena is the use of custom fly ash, a byproduct of coal combustion that has found a vital role in the production of concrete. This article delves into the characteristics, benefits, and future potential of custom fly ash in the concrete industry.

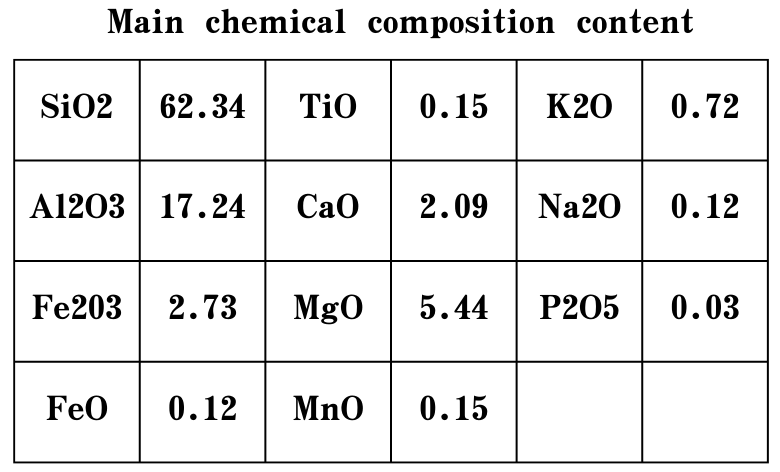

Fly ash is produced when coal is burned in power plants, and it is collected from the flue gases. Traditionally, this material has been used as a partial replacement for Portland cement in concrete, offering a range of benefits. However, the increasing need for high-quality materials tailored to specific engineering requirements has led manufacturers to explore custom fly ash solutions that cater to diverse applications.

Custom Fly Ash for Concrete Manufacturers Enhancing Quality and Sustainability

Moreover, using custom fly ash contributes significantly to sustainability efforts in construction. The concrete industry is one of the largest consumers of natural resources and a substantial contributor to greenhouse gas emissions. By substituting traditional cement with fly ash, manufacturers not only reduce the carbon footprint of their products but also promote the circular economy by repurposing waste materials. Custom fly ash can further enhance this sustainability narrative by optimizing the properties of concrete while minimizing the need for virgin raw materials.

custom fly ash for concrete manufacturers

Color and aesthetics are also essential considerations in modern construction. Custom fly ash can be engineered to achieve specific visual characteristics, allowing architects and designers to create appealing structures without compromising on performance. As the demand for unique and attractive finishes grows, the ability to modify fly ash for color and texture opens new avenues for innovative design while still leveraging its functional advantages.

Another important aspect is the ongoing research and development in the field of fly ash applications. Continuous advancements in technology allow manufacturers to explore novel ways to utilize custom fly ash, such as in 3D printing, precast concrete, and high-performance concrete mixtures. The exploration of new sources of fly ash, including alternative fuels in power generation, widens the range of materials that can be customized for specific uses.

However, the adoption of custom fly ash is not without challenges. The variability in fly ash properties based on its source can lead to inconsistencies in performance, making it imperative for manufacturers to establish robust quality control measures. A thorough understanding of the source of fly ash, along with detailed testing and certification, is critical in ensuring that the material meets the required standards.

In conclusion, custom fly ash stands as a transformative material for concrete manufacturers, providing a pathway to enhanced performance, sustainability, and versatility. By leveraging the unique qualities of fly ash through customization, manufacturers can meet the evolving demands of the construction industry while contributing to a greener future. As the market continues to evolve, the integration of custom fly ash into concrete production is set to redefine quality and innovation in the built environment.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025