Custom Ceramic Particle Factories - High-Quality Tailored Solutions

Custom Ceramic Particle Factories Revolutionizing Material Innovation

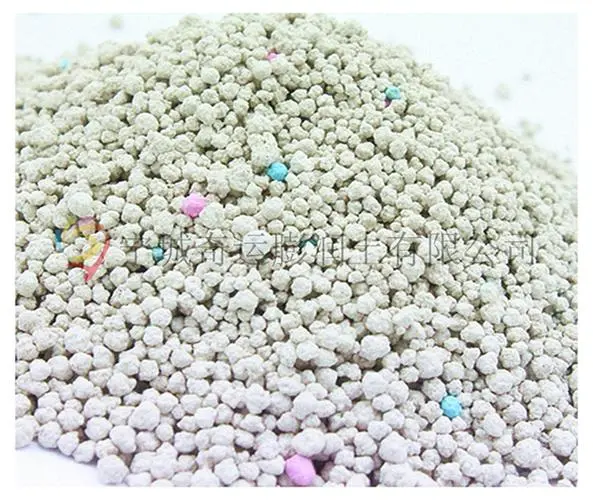

In recent years, the demand for advanced materials has accelerated, particularly in the field of ceramics. Custom ceramic particle factories are now at the forefront of this innovation, offering tailored solutions that meet the specific needs of various industries. These specialized facilities leverage cutting-edge technology to produce ceramic particles that can be customized in terms of size, composition, and properties, making them invaluable for a wide range of applications.

Ceramic materials have unique characteristics, such as high thermal stability, chemical resistance, and exceptional hardness. However, the performance of these materials is heavily dependent on the properties of the ceramic particles used in their production. Custom ceramic particle factories focus on understanding the unique requirements of their clients, allowing them to create particles that enhance the performance of end products, be it in electronics, aerospace, biomedical applications, or additive manufacturing.

One of the primary advantages of utilizing custom ceramic particle factories is the ability to produce particles of varying sizes and shapes. For instance, finer particles can be used to create smoother surfaces and improve the density of ceramic products, while larger particles might be used to achieve specific mechanical properties. Through precise control over the particle production process, manufacturers can tailor the material’s characteristics to exact specifications, ensuring that the final product performs optimally in its intended application.

custom ceramic particle factories

Moreover, these factories employ advanced techniques such as sol-gel processing, precipitation, and spray drying, as well as innovations in nanotechnology. These methods allow for the control of not only the size but also the morphology and distribution of ceramic particles. The result is a product that not only meets aesthetic and functional requirements but also pushes the boundaries of what ceramics can achieve.

Another notable aspect of custom ceramic particle production is sustainability. Many factories are now adopting environmentally friendly practices, utilizing raw materials that minimize ecological impact. This commitment to sustainability, coupled with technological advancements, has positioned custom ceramic particle factories as a responsible choice for industries looking to innovate without compromising on environmental values.

In conclusion, custom ceramic particle factories represent a significant step forward in material science. By focusing on customization, advanced production techniques, and sustainability, these facilities are paving the way for new and improved ceramic applications across various industries. As the demand for high-performance materials continues to grow, the role of these factories will become even more critical in shaping the future of ceramic technology.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025