Custom Barite Powder for Drilling - High-Quality Barite Solutions

Custom Barite Powder for Drilling A Vital Component in the Oil and Gas Industry

Barite powder, primarily composed of barium sulfate (BaSO4), plays a crucial role in the oil and gas industry, particularly in drilling operations. With its unique physical and chemical properties, barite is utilized primarily as a weighting agent in drilling fluids. Custom barite powder tailored for drilling applications is essential for optimizing performance and ensuring efficiency in various drilling conditions.

Barite's high density—typically between 4.2 to 4.5 g/cm³—gives it the ability to counteract the pressure exerted by fluids in the wellbore. This is essential in preventing blowouts and maintaining well control during drilling operations. By incorporating custom formulations of barite powder, drilling companies can achieve precise density requirements that match the specific geological formations they encounter. This is especially crucial when drilling in deep-water or high-pressure environments where conventional barite might not provide the required performance.

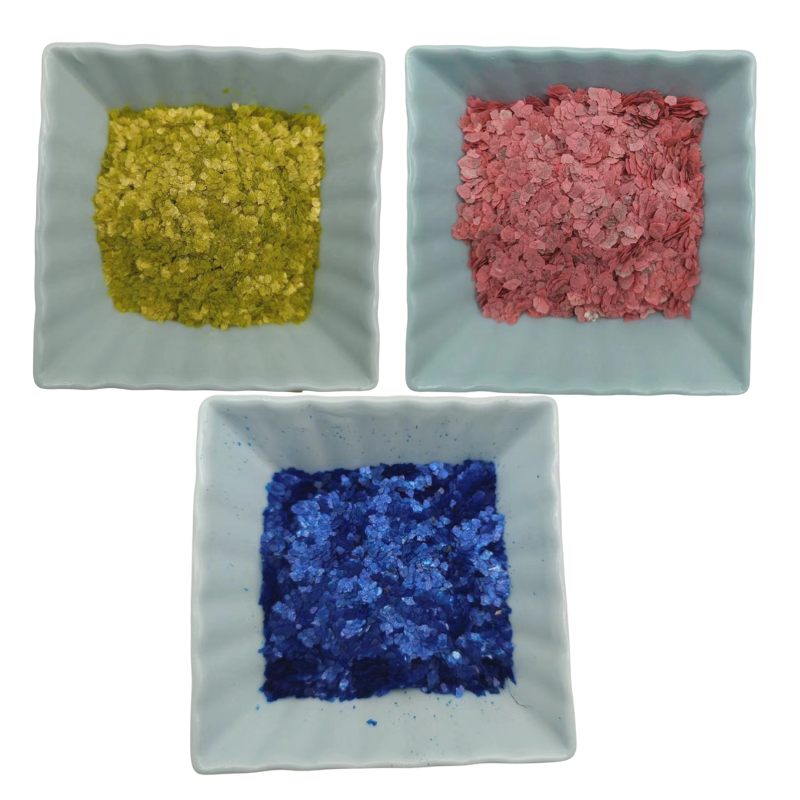

The production of custom barite powder for drilling involves careful selection of raw materials and a controlled manufacturing process to ensure consistent quality and performance. Leading manufacturers employ advanced techniques to produce barite that is finely milled and specifically treated to enhance its dispersibility and prevent sedimentation in drilling fluids. Additionally, custom blends may include additives that improve the rheological properties of the drilling mud, enhancing its performance and efficiency during operations.

custom barite powder for drilling factories

One of the significant advantages of using custom barite powder is the ability to tailor its properties to meet the specific needs of different drilling environments. For instance, in volatile regions where the risk of unexpected geological formations is high, employing a custom barite formulation can provide the necessary adaptability. Moreover, custom barite solutions can also improve the environmental impact of drilling fluids by reducing the need for additional chemicals that may alter the mud’s natural balance.

Furthermore, the demand for custom barite powder is increasing as exploration and production activities expand into more challenging terrains. Oil and gas companies are recognizing the importance of utilizing high-quality materials in their drilling operations to minimize risks and costs associated with drilling failures and inefficiencies.

In conclusion, custom barite powder is an integral part of the drilling industry, providing essential properties that contribute to safe and efficient drilling operations. As the industry continues to evolve, the need for specialized barite products will undoubtedly grow. By investing in custom barite powder solutions, drilling companies can enhance their operational capabilities and maintain a competitive edge in a rapidly changing market. With the right formulation and quality assurance processes in place, the use of custom barite powder will undoubtedly continue to play a pivotal role in successful drilling operations worldwide.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025